QOTD: How Would Tariffs Impact the Automotive Industry?

Once again, I am going to borrow today's question of the day from one of our earlier posts. I like to do this because it gives you all another forum to give your opinion about any given topic, and sometimes we can pick a particular question from a certain story and really dig in.

Today, Matt wrote about presidential candidate/former president Donald Trump's rhetoric involving tariffs and the automotive industry.

Why Did Trump Propose a 100-Percent Tariff on Mexican Auto Imports?

Earlier this week, Donald Trump suggested that he would impose a 100 percent tariff on select automobiles manufactured in Mexico — sending the industry into a minor tizzy.

Having done some digging into the matter, Trump only appears to be targeting Chinese vehicles being manufactured south of the border. The statement was made during the “Buckeye Values PAC” rally in Dayton, Ohio, and comes after Chinese automaker BYD announced plans to build a production facility in Mexico. While most of the resulting vehicles are assumed to be electric, BYD has stated its intention is not to sell them within the United States.

Report: Lithium Americas Breaks Ground in Nevada Mining Operation

Lithium Americas has broken ground on its Thacker Pass mining operations, potentially opening the door to what some are calling the largest lithium deposit in the entire world. However, it’s estimated to be another three years before refinement takes place and the materials can be adapted for use in battery powered products — including all-electric vehicles.

Possible Arson Causes Tesla to Temporarily Shutter Gigafactory Berlin

We’ve heard of automakers shuttering factories for production issues and parts shortages over the last few years, but Tesla’s recent shutdown is a new one. The automaker said it shut down production at its Gigafactory Berlin due to a potential sabotage attack, which left the facility without power.

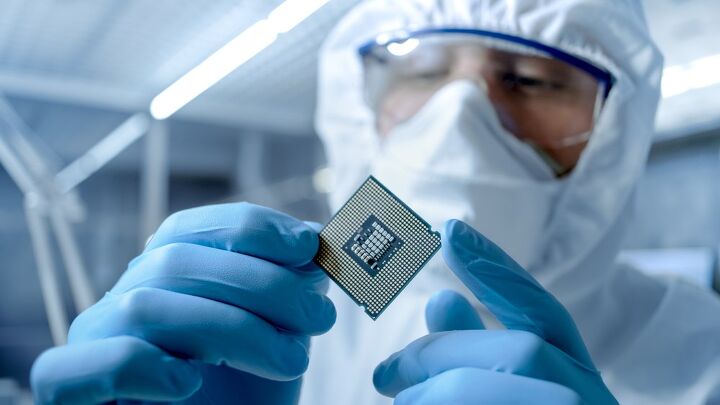

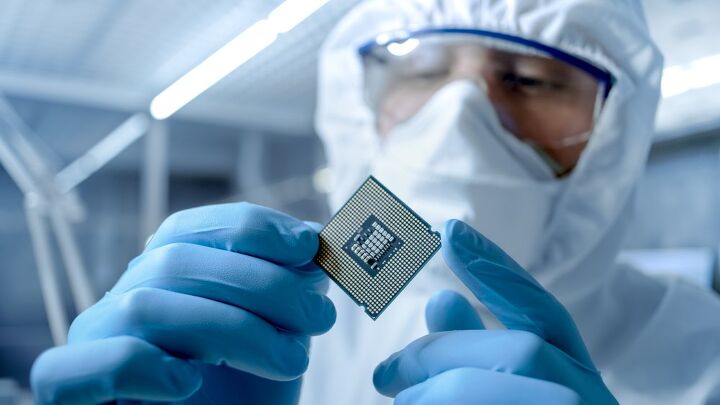

Report: U.S. Prepping $540 Million for SK Group Semiconductor Factory in Michigan

The United States Department of Energy has confirmed plans to loan $544 million to South Korean tech conglomerate SK Group under the conditions it be used to expand semiconductor production in the Midwest. Finances have been earmarked for a facility operated by subsidiary SK Siltron CSS to expand a plant located in Bay City, Michigan, which had previously expressed plans to build more chips.

Report: BYD Plotting New EV Factory in Mexico

China’s BYD is reportedly prepared to set up a new production facility in Mexico with the alleged plan to use the locale as an export hub for the United States.

Mexico has long been a convenient venue for automakers vying to sell products within the Western Hemisphere without having to pay the kind of salaries commensurate with higher living standards. American brands love sending jobs to Mexico, as does every other company interested in moving high volume models through North and South America. With BYD having previously voiced its global aspirations, setting up shop in El Águila Real seems like an obvious play.

Chips Ahoy: Manufacturers Warn of Glut

Remember when there was a shortage of microchips in the automotive industry? Pepperidge Farm remembers. According to reports, images showing fields of almost-but-not-quite completed new cars awaiting One More Chip, along with manufacturers wildly deleting features like heated seats as if they were the mob deleting computer files, could be permanently in the rear-view mirror.

Mustang Gallops Back Into Production

Customers who had thrown down money to reserve a new Ford Mustang have been playing a waiting game in recent months, with the Blue Oval pushing production back in April and again earlier this month. Now, according to several reservation holders with accounts on the 7thMustang.com fan forum, production is ramping up and should be underway by at least the end of July.

Toyota Scales Back June Production, Ford Drops German Factory

Despite starting 2022 announcing a plan to normalize output, Toyota has had trouble living up to its promise. While most automakers were figuring out how to make more money off diminished production, the Japanese brand was plotting assembly schedules that would restore assembly rates to levels that would have been considered normal prior to 2020. But the rest of the market hasn’t managed to match Toyota’s optimism and the automaker has had to scale back its global production plan yet again — citing the usual supply chain constraints stemming from COVID restrictions and worldwide deficit of semiconductors.

Meanwhile, Ford Motor Co. looks to be abandoning its vehicle assembly plant in Saarlouis, Germany. The facility produces the Focus for Europe and may be in danger of closing if the automaker elects to sell it. While the site was in the running to produce Ford’s next-gen electric vehicles, those products have since been slated for assembly in Valencia, Spain.

Report: Ferrari Plotting Italian EV Assembly Line

Ferrari is rumored to be preparing a third assembly line in Maranello, Italy, dedicated for electric vehicles. The automaker has already purchased land near the facility and is presumed to make an official announcement on June 16th when it’s scheduled to present its four-year business plan.

As usual, this comes from a major media outlet that cited unnamed sources from within the industry. Though, considering the luxury sports car manufacturer’s confirmation that it would begin producing hybrid and all-electric automobiles, it’s more than plausible. Ferrari’s first battery electric vehicles are scheduled to arrive in 2025 and it still needs somewhere to build them.

How Shanghai Lockdowns Are Changing the Auto Industry

While the semiconductor shortage was long considered the excuse par excellence for why the automotive sector couldn’t produce enough vehicles during the pandemic, some manufacturers have begun pivoting to blaming supply chains that have been stymied by Chinese lockdowns. Toyota is probably the best-known example. But the matter is hardly limited to a singular automaker and market analysts have already been sounding the alarm bell that strict COVID-19 restrictions in Asia will effectively guarantee prolonged industrial hardship around the globe.

Back in April, Shenzhen was emerging from a month-long lockdown. However, the resulting downtime severely diminished the tech hub’s output which exacerbated global component shortages. While Chinese state-run media claimed regional factories maintained full-scale production during the period, the reality was quite a bit different. Meanwhile, Shanghai has remained under harsh restrictions since March and more look to be on the horizon. As an important industrial center and the world’s busiest port by far, the situation has created an intense backlog of container ships that are presumed to create some of the sustained problems that we’re about to explore.

Chinese Lockdowns Force Toyota to Cut Production Again

The automotive industry has basically resigned itself to running with lessened production for the foreseeable future. A significant number of automakers have suggested that it might be more lucrative to scale back output, reduce overhead, and focus on achieving broader margins per car during this prolonged period of economic and logistical duress. However, Toyota started the year saying it would do its utmost to raise production output as a way to make up for losses incurred during the pandemic. The company even said it anticipated things to gradually normalize through the spring.

Unfortunately, things have not gone according to plan. By March, the Japanese automaker had lowered its output goal for the fiscal year by 500,000 global units. Another 20 percent was lopped off for the month of April and leadership began expressing concerns that those preexisting goals might be totally untenable. While there were moments with the target actually rose, Toyota has repeatedly been forced to walk those claims back as the realities of the market dashed its dreams. Now, the company is once again cutting planned output for the month of June over supply chain issues with China.

Still Interested? 2023 Acura Integra Enters Production

Acura has announced that production of the much-anticipated 2023 Integra has officially commenced in Marysville, Ohio. Deliveries of the iconic nameplate are said to commence in June and orders can be placed now.

But with pricing having revealed the starting MSRP of $31,895 — over three grand more than the mechanically similar Honda Civic Si — one wonders if the public interest has held strong. We now know that we’re effectively getting a revamped version of the ILX (also based on the Civic) with a steeper price tag and a more desirable name. The Integra comes with a 200-horsepower turbocharged 1.5-liter inline-four, mated to either a continuously variable automatic (CVT) or a six-speed manual transmission. But the CVT is standard, forcing customers that want a manual to spend $36,895 (including destination) for the A-Spec — which also comes with adaptive dampers, sportier looks, a limited-slip differential, and Acura’s technology package.

Ford Lightning Getting Company in Tennessee

The 2022 Ford F-150 Lightning has officially started production at the company’s Rouge Electric Vehicle Center in Michigan and will apparently be getting some company at the Blue Oval City campus in Tennessee. On Tuesday, CEO Jim Farley said that the upcoming plant had been selected to produce a new model during a press event covering the official launch of the all-electric F-Series.

“It’s another truck,” he explained. “This is not our only truck. We said very clearly we want to be the leader in electric pickup trucks.”

Mazda Rotary Engine Returning on MX-30

After years of speculation that Mazda would someday bring back rotary-powered performance, the company is finally willing to confirm that our collective hope was not in vain. However, there will be no rear-drive RX model spinning up its triangular Wankel beyond 8,000 rpm because piston-free rotary engines are difficult to seal. Despite making oodles of power for their size, they’re not well optimized for everyday driving and tend to offer the kind of fuel economy and emissions that get regulators’ panties in a twist.

Given the circumstances, Mazda’s rotary will be returning as a range extender for the MX-30 PHEV.

Toyota Supra Finally Getting Manual Transmission

Toyota engineers have been fairly adamant that there would eventually be a manual version of the Supra sports coupe since its formal introduction in 2019. By February of 2020, chief engineer Tetsuya Tada even confirmed that the car has been tested extensively with a clutch and choose-your-own-adventure gearbox. But Toyota explained that the automaker opted against having one at launch due to a desire to lead with the model yielding the best specs on paper. Toyota was also fretting over customers modifying vehicles, claiming the eight-speed automatic could handle far more torque before giving into physics and dismantling itself.

However, the automaker has recently begun teasing the Supra with a three-pedal setup over social media, later stating that an-all new manual transmission was indeed on the way for the coupe. But why now?

Honda Insight Being Replaced By More Hybrids Across Lineup

Ahead of Honda’s planned EVs offensive for the United States, the automaker has announced a deluge of hybrid variants of existing products. However these new vehicles will come at the expense of the Insight, which the company had just confirmed will be discontinued after 2022. In its stead will be new hybrid trips for the CR-V, Accord, and Civic — the latter of which served as the template for the passing model.

Chip Shortage Lambasts Europe, Supply Chains Confront New Problems

Even though the global semiconductor shortage has been going strong for about two years now, the world has failed to successfully manage the situation. Production stoppages remain relatively common within the automotive sector, with manufacturers continuing to attribute factory stalls to an inability to procure a sufficient number of chips. But the excuse seems to have evolved into a catch-all explanation for supply chain issues that continue that go beyond a single missing component.

That makes it a little hard to determine precisely how much of the ongoing production shortfalls can be pinned on semiconductors. But AutoForecast Solutions (AFS) was keen to take a whack at it and determined roughly 1.4 million vehicles have been removed from the automotive industry’s targeted output for 2022 — that’s on top of the 10.5 million units we lost in 2021. While the issue is indeed global, AFS stated that the last batch of vehicles to get the ax was predominantly from Europe.

GM's Oshawa Plant Increasing Truck Production, CAMI Getting Electric Vans

On Monday, General Motors’ added a second shift for Heavy Duty variants of the Chevrolet Silverado at Oshawa Assembly to ensure the automaker can meet demand. There are also plans to launch a third shift to spur production of light-duty pickups after GM spent the last two years struggling to deliver vehicles in a timely manner.

GM Canada recently representatives from the Canadian federal government, eager to show that its $2 billion investment into Ontario manufacturing (specifically at Oshawa and CAMI Assembly) had already borne fruit. While this is said to eventually include the production of BrightDrop’s all-electric and perpetually connected Zevo vans, GM is presently focused on swelling production on some of its most valuable products.

Ford, GM Pausing Production in Michigan Over Parts Shortage

Ford Motor Co and General Motors will be individually suspending production in Michigan next week due to supply chain constraints. However, it’s difficult not to notice that the chosen facilities are responsible for lower-volume models they could probably afford to idle.

GM is stalling Lansing Grand River Assembly and Stamping, citing a parts shortage it said had nothing to do with the ongoing deficit of semiconductor chips. The company later stated that the Russo-Ukrainian war had not played a factor, abandoning the two most popular excuses for why something isn’t being done in 2022. Meanwhile, Ford has said the chip shortage has everything to do with its temporary closure of Flat Rock Assembly.

Auto Industry Assets Could Be Seized by Russian Nationalization

The war in Ukraine continues to have ripple effects.

A new report from industry bible Automotive News suggests Vladimir Putin is considering seizing the assets of automakers who left Russia in the wake of its invasion of Ukraine.

Will Toyota's Production Pause Go Global?

Following last week’s announcement where Toyota explained its need to scale back Japanese production by 20 percent this April, the automaker has outlined planned slowdowns for the foreseeable future. It’s citing all the usual problems. Countries are still employing various COVID-19 restrictions that are upending supply chains, semiconductor production for automobiles remains insufficient, and there’s a war in Eastern Europe that’s creating all-new troubles while exacerbating some of the more familiar ones. But scaling back output might not be the death sentence it sounds like.

With last year resulting in 10 million deliveries worldwide, Toyota actually managed to improve its sales against 2020’s year-over-year global production decline of 12 percent. And the last two years have also yielded enhanced profitability for the automaker, despite it having expressed repeated concerns about procuring enough components to keep popular models (like the RAV4) in stock. In 2021, Toyota saw $249.4 billion in revenue and even became the best-selling automaker in the United States, dethroning former top-dawg General Motors.

Ford Outlines EV Production Strategy for Europe

Ford Motor Co. has shared its intent to launch seven fully electric vehicles in Europe, including a battery-electric variant of the Puma subcompact crossover, its best-selling (and looking) passenger car for the market. Though the first EV in its new product offensive will be a midsize crossover helping Blue Oval deliver on a previous promise to manufacture electric vehicles in Cologne, Germany.

The unit is said to capitalize on Ford’s partnership with Volkswagen Group by leaning on the latter entity’s MEB platform that already underpins VW’s ID products and Audi’s e-tron vehicles. Driving range is estimated at 311 miles per charge, with the company anticipating a formal debut later this year.

Toyota Cutting Production By 20 Percent Next Month

Earlier this week, we covered Toyota stressing over the feasibility of its current production plans. Automakers around the world are presently trying to suss out how to maintain solid profitability with diminished output, with Japan’s largest manufacturer suggesting the present state of the world might force it to do likewise.

While we assumed the resulting decisions would take a couple of weeks for Toyota to finalize, as it considered its many options, the company announced on Friday that it would need to cut domestic production by 20 percent for the month of April. The automaker framed this as part of its preexisting “recovery plan” necessary to account for supply chain issues that never seem to end, saying that diminished output would gradually normalize in Japan over the spring.

Toyota Considers New Production Strategy As World Burns

Toyota Motor Corp. is reconsidering its existing production strategy, citing ongoing global issues that are hindering its ability to manufacture vehicles at a normal pace.

Like most other automakers, Toyota has endured COVID restrictions, supply chains bottlenecks, component shortages, at least one cyberattack, and some new obstacles stemming from Russia’s invasion of Ukraine. These issues have already encouraged General Motors to pursue lower output as it focuses on selling on higher-margin vehicles. Though it’s hardly the only automaker signaling diminished production for 2022. Even the National Automobile Dealers Association is assuming 2022 will be another year of extra-tight inventories and wild markups. It’s something the industry was already doing, with Toyota becoming the next company opting to rejigger its targets to account for hard times.

Audi Approved for $3.3 Billion EV Factory in China

Audi and FAW Group, the state-owned partner it is effectively required to have in order to preferential treatment from the Communist Party of China, received some good news this week. Government officials have approved the duo for a new, jointly operated production facility in Changchun.

With Volkswagen Group having shifted its focus toward China in recent years, the market has become all-important for the German company. VW is currently the top-selling brand for the entire region, with its Audi subsidiary typically being the highest volume premium automaker from Europe. Building in China is good optics for brands hoping to remain popular there and has the added benefit of placing manufacturing complexes closer to relevant suppliers, especially if you’re swapping to electric vehicles.

Porsche Becoming Volume Brand

While it may not be on the cusp of supplanting Toyota in terms of sales, the Porsche brand has enjoyed relatively consistent growth since 2009. Despite 2020 representing a poor sales year for just about everyone who wasn’t producing vaccines, the German manufacturer weathered the storm better than most and came back to break a few records the following year.

By the end of 2021, Porsche had sold nearly 302,000 vehicles globally. It also managed to break its previous sales records in China and the United States. Considering that global production volumes have remained suppressed by supply chain problems, it was an impressive accomplishment. However, Detlev von Platen, Executive Board Member Sales & Marketing at Porsche AG, believes the automaker can still outdo itself in 2022.

Tesla Cybertruck Delayed Until At Least 2023

During last week’s earnings call, Tesla CEO Elon Musk confirmed that the Cybertruck would be delayed until at least 2023. That places the polygonal pickup two years behind its original schedule. But who among us with knowledge of the automaker’s production history actually thought it would be delivered on time?

Delaying products has become a hallmark of the Tesla brand and Musk doesn’t seem to be sweating it. Rather than focusing on launching a new vehicle for 2022, the business wants to prioritize increasing capacity and finalizing its move from California to Texas. Now based in Austin, Tesla made $5.5 billion last year compared with the previous record year of $3.47 billion in net income posted in 2020. Musk said the shift into routine profitability is proof that EVs are viable, adding that the company could have done even better if factory output hadn’t been so constrained last year. Unfortunately, those hurdles haven’t dissipated for 2022, encouraging the automaker to wait on both the Tesla Cybertruck and Roadster.

Volkswagen Passat Passes Away

The final Volkswagen Passat has rolled off the assembly line in Chattanooga, Tennessee, ending the model’s extended run on the North American market.

Designed by Giorgetto Giugiaro and introduced in 1973 using the VW/Audi B1 platform, the Passat arrived in the United States as the Dasher and was sold as a midsized luxury vehicle to people in the market for an imported economy car. The model carried different names in other parts of the world and even saw a few unique monikers used in the U.S. (e.g. Quantum) to help differentiate between the hatchback, sedan, and wagon variants sold throughout the 1980s. But it was officially known as the (B2) Passat by 1990, regardless of format.

Ford Pausing Reservations on Maverick Hybrid Until Summer

Ford’s sales success with the Maverick pickup has been undeniable. But if you’re in need of more evidence, the automaker has begun notifying dealerships to stop taking reservations on the base hybrid model because it doesn’t even think it can keep up with the existing backlog.

Will Intel's Ohio Chip Plants Fix Automotive Supply Chains?

Intel has announced a $20 billion investment to transform a 1,000-acre plot in New Albany, Ohio, into the latest addition to its U.S. chip-manufacturing hub. Construction is scheduled to commence later this year with operations starting in 2025. But everyone’s wondering if it is going to be enough to rectify the pathetic state in which domestic vehicle production currently finds itself.

Toyota Confronting Widespread Factory Stalls in Asia

Toyota Motor Corp is currently having to contend with idle factories in Asia, reducing the automaker’s estimated output by over 47,000 units this month. Shockingly, it’s not alleged to have anything to do with the semiconductor shortage that’s been wreaking havoc on Western markets.

With chip production having been localized primarily in China and Taiwan, Asian suppliers have had better access to them. But Eastern markets have still been subjected to other routine plant closures due to supply chain restrictions stemming from the pandemic. Existing protocols in China, combined with renewed restrictions in Japan, have created a situation impacting numerous automakers with Toyota announcing this week that it probably won’t reach its goal of manufacturing 9 million cars this year — though it made sure to include the ongoing semiconductor issue as relevant.

Mustang Production Paused at Flat Rock Assembly

Ford will be idling Mustang production this week due to an insufficient supply of semiconductor chips. For all the talk the industry made about getting over supply chain hurdles in 2021, manufacturers continue citing insufficient access to microchips as the primary obstacle preventing them from enjoying more routine operations.

The automaker confirmed the move on Tuesday, explaining that Michigan’s Flat Rock Assembly will be down until sometime next week.

McLaren Artura Delayed Again for the Usual Reasons

McLaren has confirmed that it will be delaying the launch of its new hybrid supercar, the Artura, until the summer of 2022. Slated to commence deliveries by the end of 2021, the company has stated that the chip shortage has forced a revised timeline.

The semiconductor shortage has been a popular excuse for automakers the world over and may still be valid. Chip manufacturers have continued prioritizing the production of newer, more advanced components yielding higher margins. However, these units typically do not make their way into automobiles and are more commonly found in smaller electronic devices.

Corvette Production Halted Over Kentucky Tornadoes, TMMK Okay

Chevrolet’s Corvette plant in Bowling Green, Kentucky, will be seeing a week of downtime following the vicious tornadoes that swept through the United States over the weekend. With twisters populating Southern and Midwestern states, Kentucky became ground zero from some of the most devastating weather seen all year.

Governor Andy Beshear called for a state of emergency Saturday due to the extensive damage across the state, with Bowling Green yielding some of the most harrowing examples. While the Corvette factory was spared the total destruction endured by other buildings, General Motors has said the site will still need to remain closed so the necessary cleanup can be done.

M1 Successor? BMW Previews 750-Horsepower XM Hybrid Concept

It’s been decades since BMW introduced a dedicated M car, so imagine our surprise when we learned the next one would be a boxy SUV. Considering the last standalone M was the ground-hugging wedge that was the M1 coupe, we have to assume M Division engineers were either trying to challenge themselves or someone higher up figured they could make more money selling a utility vehicle.

While just a concept at present, the BMW XM boasts a fairly radical design. But the manufacturer has claimed it will retain over 90 percent of the prototype’s good (?) looks when it enters into production. There’s a lot of interesting stuff here that might make it into the finished product, including the extra-thin daytime running lights that sit atop the real headlamps that have been snuck behind tinted glass. It’s a strange beast that doesn’t seem like it’s targeting the traditional M shopper and, according to BMW, that’s because it isn’t.

Rumor Has It Rivian Will See More Production Delays

Rivian may be experiencing more production delays. Maybe this is why it now apparently has a delivery-time estimator on its build site?

Toyota, Stellantis Announce North American Battery Plants

Automakers Toyota and Stellantis separately announced plans to construct lithium-ion battery plants in North America on Monday. With regulatory pressures mounting, the industry has been shifting its eggs between baskets to avoid trouble. But the ultimate goal for most brands is to transition toward selling EVs, requiring meaningful action and financial expenditures on the part of manufacturers.

We’ve already seen General Motors and Ford Motor Co. squabbling over who will nestle the biggest battery facilities between America’s Frost and Sun Belts. It’s only fitting that the remnants of the Chrysler Corporation contained in Stellantis walk the path of electrification, especially now that it’s absolutely riddled with European influence. Meanwhile, Toyota is predictably exercising a bit of caution as it similarly navigates how to modernize itself via upcoming lithium-ion plants.

Car Loans Get Longer, Rental Vehicles Get Older

While nobody needs to tell you that the economy isn’t in good health, we should at least hip you to the latest automotive trends relating to the financial purgatory we’re currently living through. Ford sent a memo to dealers last week indicating that it would be removing the minimum FICO requirement for 84-month financing, indicating that the industry may soon normalize auto loans that are even longer than the 72-month whoppers that have grown in popularity over the last several years.

Meanwhile, those needing a vehicle intermittently will find that rental rates have not been declining as hoped. Despite analysts previously suggesting that auto pricing may stabilize through the fall, we now look to be going into the holidays facing familiar high-priced troubles — and there’s really no reason to think that’s going to change after 2022 gets here.

UK Vehicle Registrations Fall Into Bottomless Pit

Despite manufacturers still managing to turn a profit, the automotive sector hasn’t been in the best of health these last few years. Growth appears to have plateaued in most Western nations, encouraging companies to cater this business toward other markets, supply chains have also been negatively impacted by the pandemic — with semiconductor shortages hindering production schedules on a scale we’ve not seen since the Great Recession.

It’s a bad situation and rumored to get worse if the warning cries of economists are to be believed. But there’s also mounting evidence to support their claims. The Society of Motor Manufacturers and Traders (SMMT) recently reported that vehicle registrations in the United Kingdom fell by roughly 35 percent in September vs the same timeframe in 2020. This is relevant because the month typically represents the second-busiest period for the country and numbers were already low due to production stops created by coronavirus lockdowns.

Will Chip Shortage Dethrone GM's Sales Dominance?

Ninety years. That’s the amount of time that General Motors has led the sales charts in the U.S.

That may change this year, according to industry bible Automotive News, because of the ongoing microchip shortage.

Lucid Motors Becomes an Automaker

Production of the 2022 Lucid Air started this week, adding another automaker to the North American roster. The manufacturer held an event on September 28th, inviting Arizona Governor Doug Ducey, relevant executives, big-time investors, select media outlets, and customers who dropped $170,000 to purchase the limited Dream Edition of the electric vehicle.

While often framed as a Tesla ripoff, Lucid Motors has been setting its sights so high that it hardly feels like a fair assessment. Because the Air is offering one of the most impressive all-electric spec sheets in the industry right now and should probably worry the competition.

German Automakers Aren't Interested in Returning to Normal

With supply chain hiccups crippling the automotive industry’s ability to conduct business as normal, resulting in rolling production stalls and skyrocketing vehicle prices, manufacturers looked to be in serious trouble throughout the pandemic. But we learned that wasn’t to be the case by the summer. Automakers were posting “surprise profits” because people still needed cars. We also found out there’s been a growing appetite for expensive (see: highly profitable) models and the industry saved itself a bundle by not needing to pay for office space or line workers, as COVID restrictions kept everyone at home.

Having considered the above, most automakers are seriously considering how they can further leverage this new modality. German manufacturers have even said they’re not that interested in going back to the normal way of doing things — instead electing to intentionally limit volumes and focus on high-end models that will yield the greatest return on investment. But it’s not quite the curveball it seems, as some companies were already ditching the volume approach.

Place Your Bets: German Gigafactory Operational By October?

Tesla Gigafactory has been hit with more red tape than a last-minute Christmas present and is reportedly nearing completion. Elon Musk even suggested the facility could be producing vehicles by the end of October. However, some of the language emanating from his recent 0n-site engagement has us wondering what the odds are on that becoming a reality. The facility has already been delayed on more than one occasion by environmental activists and bureaucratic hang-ups. Though it now appears to be within a few weeks of commencing operations, Tesla’s CEO didn’t sound overly optimistic about the target.

On Friday, Musk met with Armin Laschet — Germany’s leading Conservative candidate to succeed Angela Merkel as chancellor — to tour the grounds of Gigafactory Berlin (technically Gruenheide). Though the main event was Elon’s preceding meeting with local Brandenburg officials that have not yet given final approval on the facility, citing ecological concerns.

More Ford Delay Woes: Chip Shortage Slows Mach-E Deliveries

If today’s news regarding production delays at Ford was a game of Clue, the first victim would be Bronco, caused by hardtops. Now it’s Mach-E, with lack of chips being the weapon.

Ford Bronco Hardtops to Be Replaced, Delays Continue

Ford is continuing to have hard-top issues with the Bronco. So much so, that according to Bronco6G via Autoblog, the company will replace all the molded-in-color hardtops it has built up to now.

Tesla Cybertruck Delayed Until 2022

Tesla’s Cybertruck has been delayed. The automaker updated its online vehicle configurations to reflect that the model will no longer be arriving in 2021. The pickup’s new launch date is set for sometime in 2022, with no hints on what part of the year the company plans on getting the assembly lines humming.

Though there’s little reason to get bent out of shape. Tesla has always been notorious for delaying vehicles and the automotive sector is currently in a state where you’d probably be more shocked to learn that Cybertruck was arriving on time. Besides, Tesla now has more time to dangle the model in front of consumers as a way to keep itself relevant.

Tesla Cybertruck Production Appears Delayed Until 2022

Comments made by Tesla boss Elon Musk and other company execs on an earnings call seem to suggest that Tesla Cybertruck production may be delayed.

That doesn’t necessarily mean the truck will be a flop, as I’ve predicted, but it’s not great news for Tesla, either.

Chip Shortage Leads to 'Dead' Cars On Factory Lots, GM Halts Truck Production

Have you heard the one about the dead cars? No, not the ones we find in junkyards, but the ones that haven’t had life yet, thanks to the chip shortage.

Tesla's German Factory Needs Help From Shanghai

Despite achieving a miraculous global expansion in a period where established industrial conglomerates and regulatory hurdles make it nearly impossible for new automakers to persist, Tesla’s German facility is running behind schedule. Production at the Gruenheide plant (aka Giga Berlin or Gigafactory 4) was originally planned to commence this month, with deliveries kicking off shortly thereafter. But those targets have been shifted closer to the end of this year or the more likely scenario of early 2022.

As Tesla would still like to supply the market, its facility in Shanghai will begin shipping vehicles to Europe in August until local production can be achieved. Model Y crossovers will be imported from China until its German site has its assembly lines humming, which has turned out to be a harder task than the automaker anticipated.

Stellantis Plots More Factory Downtime, Ford Loses Tech Chief

Stellantis plans to extend the typical summer downtime at a couple assembly plants while relaunching production at Windsor Assembly next month. The Canadian van factory will be see two shifts returning on July 5th, while its Belvidere Assembly Plant in Illinois and Toluca Assembly Plant in Mexico will be idled due to the ongoing semiconductor shortage. This has become a common tactic within the automotive industry, with our doubting it’ll be the last occasion we’ll be reporting on extended summer vacations.

Meanwhile, Ford Motor Co. appears to have lost its technology chief to Amazon. Ken Washington was hired into Blue Oval after a stint with Lockeed Martin in 2014 and will be leaving the automaker next month to become vice president of software engineering for the tech giant.

Subaru Getting Super Screwed By Semiconductor Shortage

The global semiconductor shortage has been particularly hard on Western automakers, though it’s not been peaches and cream for Asian brands. Following news that Nissan had run into issues resulting in additional downtime this summer, we’ve learned that Subaru is currently operating with a scant, nine-day supply of product and will be required to conduct more plant closures due to a lack of chips.

Having already stalled its Yajima plant on multiple occasions, as well enacting work stoppages at Subaru of Indiana Automotive (its U.S. facility), this is hardly where the brand wanted to find itself going into the warmer months. On Friday, Subaru announced it would be idling two plants in Japan’s Gunma prefecture this July.

Polestar Announces Electric SUV Will Be Made in America

Volvo-owned Polestar has announced that its upcoming “performance SUV” will be manufactured within the United States, starting late in 2022. The model will be assembled alongside other Volvo products at the Swedish company’s facility in South Carolina. It also provides an opportunity for Chinese parent Zhejiang Geely Holdings to make meaningful moves on the North American marketplace and less ammunition for critics to reference the EV-focused Polestar as a foreign brand.

“Polestar 3 will be built in America, for our American customers,” said Polestar CEO Thomas Ingenlath. “I remember the great response when I first shared Polestar’s vision here in the USA and I am proud that our first SUV will be manufactured in South Carolina. From now on, the USA is no longer an export market but a home market.”

QOTD: Should the U.S. Produce Its Own Semiconductor Chips?

Now that it’s effectively too late to avoid a crisis, the United States has begun asking itself whether or not now is the time to put into motion a plan that will eventually lead to the nation manufacturing its own semiconductor chips. As you’re undoubtedly aware, the automotive sector has taken a beating as Asian-based supply chains are experiencing what can only be described as unprecedented demand. But they aren’t building enough to satisfy everyone and the local markets are taking precedent.

U.S. Commerce Secretary Gina Raimondo proposed a $52-billion solution on Monday that would cram fresh government funds into production and research that could result in seven to 10 new U.S. factories. But that’s just to get the ball rolling on an industry that will take several years to mature, leaving some to wonder whether the country should even bother.

Tundra Versus the F-150 – What's Wrong With Toyota?

Can the Toyota Tundra go toe-to-toe with the Ford F-150, and does it make sense to try? The F-150 is the most popular vehicle in the U.S., despite a 12 percent drop in sales. Ford still managed to sell 787, 422 F-150s in 2020. Toyota sold a little over 109,000 Tundras in 2020, down two percent from 2019. While that sounds like the Tundra did well, it only outran the Nissan Titan.

Vehicle Miles Traveled On The Rise Again

In March, vehicle miles traveled (VMT) rebounded to pre-pandemic levels. According to the Auto Care Association, this was the first month since August 2019 that VMT topped 300 million miles. To give you some perspective, the distance between the earth and the moon is only 238,856 miles, according to Wikipedia.

Kia 2021 Seltos and 2020-21 Soul Are Flaming Hot

Kia has recalled 2021 Seltos SUVs and 2020-21 Soul wagons with 2.0-liter, four-cylinder engines. 147,249 vehicles are involved. Inconsistent piston ring heat treating may cause engine damage. This can lead to a loss of power, and an increased risk of fires or crashing.

Rental Car Companies Reeling From Uptick in Travelers

Rental car companies are their own worst enemies, having sold off much of their fleets during the pandemic’s height. With travel restrictions easing in many places they find themselves with no inventory.

Auto Industry Requests U.S. Government Help With Chip Shortage

The Alliance for Auto Innovation (AAI) is hard at work begging the federal government for help while the world continues coping with the semiconductor chip shortage, though it’s hardly the first time the industry has asked for or received administrative assistance. With pandemic lockdowns throwing global supply chains into a tailspin, U.S President Joe Biden said his administration would be seeking $37 billion and new legislation to address the chip shortage while federal agencies were directed to see what could be done in the interim.

But there’s little to be done with the brunt of the relevant manufacturing taking place in Asia, hence the AAI lobby requesting U.S. Commerce Department set aside some cash for domestic chip production in a new bill.

Mercedes Spending $59 Million to Build ESprinter in U.S.

On Tuesday, Mercedes announced it would be pouring roughly $59 million (€50 million) to build the all-electric Sprinter van at three facilities. One of them will is the American MBV factory in Ladson, South Carolina, with the remaining two sites naturally situated in Düsseldorf and Ludwigsfelde, Germany.

Over 200,000 Sprinter and Metris model vans have been assembled in the United States since 2006, though the automaker had actually been using the state to avoid the chicken tax for much longer. Considering the region is the second-largest market for Sprinter vans, Mercedes is not interested in dissolving its American commitments either. The investment will be spread across the three facilities for the necessary tooling to build the EV variant the automaker already started selling in Europe.

Recent Comments