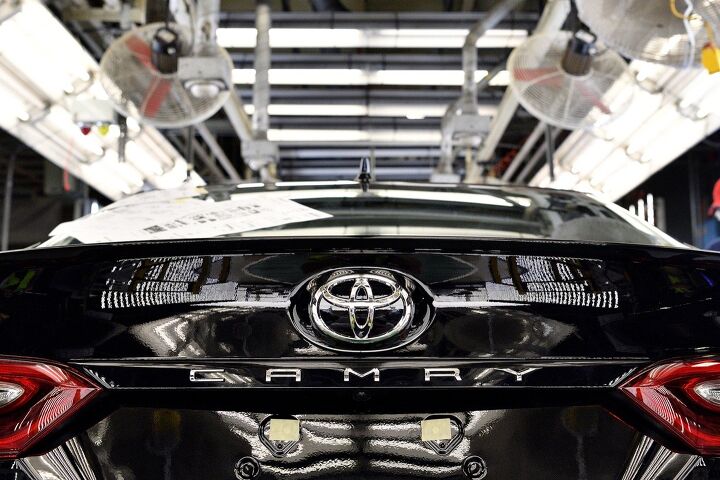

Toyota Scales Back June Production, Ford Drops German Factory

Despite starting 2022 announcing a plan to normalize output, Toyota has had trouble living up to its promise. While most automakers were figuring out how to make more money off diminished production, the Japanese brand was plotting assembly schedules that would restore assembly rates to levels that would have been considered normal prior to 2020. But the rest of the market hasn’t managed to match Toyota’s optimism and the automaker has had to scale back its global production plan yet again — citing the usual supply chain constraints stemming from COVID restrictions and worldwide deficit of semiconductors.

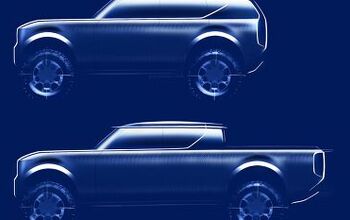

Meanwhile, Ford Motor Co. looks to be abandoning its vehicle assembly plant in Saarlouis, Germany. The facility produces the Focus for Europe and may be in danger of closing if the automaker elects to sell it. While the site was in the running to produce Ford’s next-gen electric vehicles, those products have since been slated for assembly in Valencia, Spain.

Ford explained its decision in a corporate release, saying that its commitment to Germany will be retained via a $2-billion investment in a state-of-the-art electric vehicle center in Cologne. Production is scheduled to commence there in 2023 and focus on vehicles borrowing Volkswagen’s MEB electric platform. However, the company decided that Spain was simply “best positioned” to produce EVs using its own next-gen architecture.

“We are committed to building a vibrant, sustainable business in Europe as part of our Ford+ plan, and that requires focus and making tough choices,” stated Jim Farley, Ford president and CEO. “The European auto industry is extremely competitive, and to thrive and grow we can never settle for less than unbelievably great products, a delightful customer experience, ultra-lean operations and a talented and motivated team.”

That last line bolsters preexisting assumptions that Ford knows it wouldn’t have paid Spanish workers as much as their German counterparts. However, the manufacturer hasn’t outright said the Saarlouis facility was doomed, just that its fate was up in the air.

Though both plants will still see staffing reductions as EVs simply require fewer employees to assemble (one of the reasons automakers are so interested in EVs to begin with). Valencia currently has around 6,000 employees building the Kuga, Galaxy, and S-Max for the European market. By contrast, Saarlouis only has about 4,500 people and endured more work stoppages due to supply chain issues. Ford confirmed that the German plant will end Focus production in 2025, saying it will be looking for “alternative opportunities” for vehicle production. This apparently does not exclude selling the plant off to another automaker.

Getting back to Toyota, the company has stated that it’s scaling back its production plan for July by 50,000 units. While the manufacturer has said it would adhere to its annual global production target of 9.7 million vehicles, it has also spent the last several months tamping down output. Most of this has been attributed to Chinese lockdowns persisting into 2022, though the brand has likewise noted that it’s been difficult to source chips due to the ongoing semiconductor shortage. It’s kind of tragic, considering Toyota was one of the few auto brands that actually seemed interested in business returning to normal.

As of today, the company said it still expects to build 800,000 vehicles during July. However, Toyota made sure to explain that’s more of a moving target than a real guarantee.

“As it remains difficult to look ahead due to the shortage of semiconductors and the spread of COVID-19, there is a possibility that the production plan may be lower. However, we will examine the parts supply closely to minimize sudden decreases in production, and continue to make every effort possible to deliver as many vehicles to our customers at the earliest date,” the Japanese automaker said in a release.

[Image: Toyota]

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- ToolGuy If these guys opened a hotel outside Cincinnati I would go there to sleep, and to dream.

- ToolGuy Michelin's price increases mean that my relationship with them as a customer is not sustainable. 🙁

- Kwik_Shift_Pro4X I wonder if Fiat would pull off old world Italian charm full of well intentioned stereotypes.

- Chelsea I actually used to work for this guy

- SaulTigh Saw my first Cybertruck last weekend. Looked like a kit car...not an even panel to be seen.

Comments

Join the conversation

This is just the beginning my friends: https://journal-neo.org/2022/06/21/global-planned-financial-tsunami-has-just-begun/

I heard that Toyota is getting out of the automotive business.