Tesla Hires Former Audi Exec to Oversee Production as Report Slams Imported Labor at Fremont Factory

In a bid to get the Model 3 out the door on time, ideally without the snafus that plagued the Model X, Tesla Motors has hired a longtime Audi executive to serve as vice-president of vehicle production.

The hiring of 22-year Audi veteran Peter Hochholdinger, first reported by Reuters, comes as Tesla ramps up its manufacturing capacity to handle the 400,000 reservations placed on its upcoming $35,000 sedan.

Amid the company’s all-out dash to bring its Fremont, California factory’s production capacity to 500,000 vehicles per year by 2018, a damning report just released by the Bay Area News Group sheds light on the low-cost foreign labor helping to build that capability.

The report details a group of Slovenian and Croatian laborers brought into the U.S. on business visas to help build the Fremont factory’s new paint shop last year.

The workers, one of whom sustained a serious injury in a fall at the Tesla paint shop, were among many eastern European men hired by overseas contractors to work in the U.S., despite having few qualifications. The group at the Tesla plant worked up to 10 hours a day, six days a week, and received compensation to the tune of $5 an hour.

Neither Tesla nor the contractor have accepted responsibility for the practice, which critics say violates labor and visa laws. Local trades groups aren’t happy about the jobs going to the imported workers.

Because the hiring and compensation occurred through a private contractor, the automaker absolved itself of blame for the working conditions, telling the media group, “Tesla expects all its contractors and their subs … to comply with all applicable pay laws.”

While the foreign labor issue is one that impacts many companies, not just Tesla, the automaker’s focus remains on bringing the Model 3 to market in big numbers by late 2017.

After the botched roll-out of the Model X SUV due to supplier issues, Tesla purged Greg Reichow, the company’s former vice-president of production, and Josh Ensign, vice-president of manufacturing, from its ranks.

Hochholdinger’s job is to boost production of existing models while creating a cost-conscious manufacturing program for the Model 3.

Putting all of the pieces together in a timely fashion is key. Founder and CEO Elon Musk already announced on Twitter that tardy buyers might have to wait until 2019 to see delivery of their Model 3.

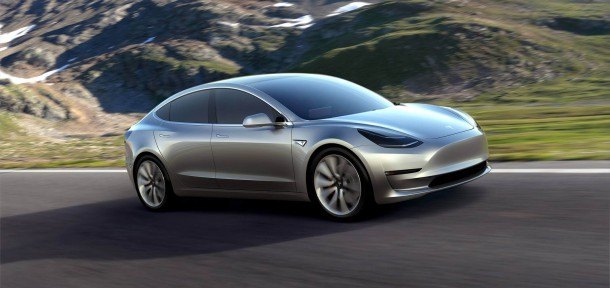

[Image: Tesla Motors]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Kjhkjlhkjhkljh kljhjkhjklhkjh A prelude is a bad idea. There is already Acura with all the weird sport trims. This will not make back it's R&D money.

- Analoggrotto I don't see a red car here, how blazing stupid are you people?

- Redapple2 Love the wheels

- Redapple2 Good luck to them. They used to make great cars. 510. 240Z, Sentra SE-R. Maxima. Frontier.

- Joe65688619 Under Ghosn they went through the same short-term bottom-line thinking that GM did in the 80s/90s, and they have not recovered say, to their heyday in the 50s and 60s in terms of market share and innovation. Poor design decisions (a CVT in their front-wheel drive "4-Door Sports Car", model overlap in a poorly performing segment (they never needed the Altima AND the Maxima...what they needed was one vehicle with different drivetrain, including hybrid, to compete with the Accord/Camry, and decontenting their vehicles: My 2012 QX56 (I know, not a Nissan, but the same holds for the Armada) had power rear windows in the cargo area that could vent, a glass hatch on the back door that could be opened separate from the whole liftgate (in such a tall vehicle, kinda essential if you have it in a garage and want to load the trunk without having to open the garage door to make room for the lift gate), a nice driver's side folding armrest, and a few other quality-of-life details absent from my 2018 QX80. In a competitive market this attention to detai is can be the differentiator that sell cars. Now they are caught in the middle of the market, competing more with Hyundai and Kia and selling discounted vehicles near the same price points, but losing money on them. They invested also invested a lot in niche platforms. The Leaf was one of the first full EVs, but never really evolved. They misjudged the market - luxury EVs are selling, small budget models not so much. Variable compression engines offering little in terms of real-world power or tech, let a lot of complexity that is leading to higher failure rates. Aside from the Z and GT-R (low volume models), not much forced induction (whether your a fan or not, look at what Honda did with the CR-V and Acura RDX - same chassis, slap a turbo on it, make it nicer inside, and now you can sell it as a semi-premium brand with higher markup). That said, I do believe they retain the technical and engineering capability to do far better. About time management realized they need to make smarter investments and understand their markets better.

Comments

Join the conversation

Looking through Eisenmann's press releases, it looks like they've been hired by a number of auto companies. I see Volvo, Mercedes, VW, BMW, and FCA. Probably others. So, if you're gonna bitch about Tesla hiring this company, it's probably safe to say the same thing has happened at these other auto manufacturers as well.

So why are we importing auto workers? These visa programs exist for trades which there isn't a pool of skilled workers in the country to hire from. Last time I checked we had a few unemployed auto workers. Of course they get paid more than minimum wage. So it isn't a case of "there is nobody to do the job", but rather a case of "We don't want to pay what the US market has decided an auto worker is worth". The pendulem swings back and forth and these sort of shenanigans are what leads to union shops. Also, substitute "Tesla" with "Trump" in this article and me thinks many of the voices that are OK with this would be crying foul.