Will Morgan Build The First-Ever Multi-Gear EV?

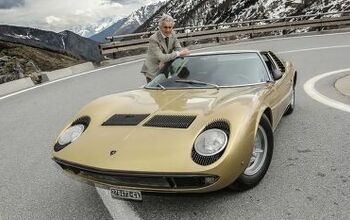

Rattle off a list of the buzzworthy EV makers that seem likely to achieve the “holy grail of EV development,” a multi-gear electric car, and chances are that firms like Tesla, Fisker, Th!nk or even a major OEM like Nissan will make the cut. You probably wouldn’t consider the ultra-conservative British sportscar maker Morgan to be in the running, as they still build body substructures out of wood… surely the brand that’s most stuck in the early 20th Century seems an unlikely candidate for EV technical leadership. Think again…

GreenCarCongress reports that Morgan is working on something called the +E, an electrified version of its Aero 8 sportscar, with prototype production scheduled for early 2012. And believe it or not, the plan is to send 221+ lb-ft of zero-rpm torque through a “conventional manual transmission.” That’s right all you Silicon Valley hotshots and US DOE grant-receivers: the most advanced EV may just be developed by a firm that was long said to be “stuck in the 1930s.”

Part-funded by a $166k R&D grant from the Niche Vehicle Network CR&D Program, the +E will be made by replacing an Aero 8’s BMW V8 and replacing it with a variation of Zytek’s innovative electric drivetrain. The Zytek drivetrain, which is known for its extremely compact packaging, is also being used for GOrdon Murray’s T.27 electric city car ( click here for more on the drivetrain). Featuring lithium-ion batteries, the rear-drive +E will take advantage of Zytek’s extensive research into hybrid and KERs technology (the firm supplied technology for the first Grand Prix-winning KERS system).

But the most important development is the use of a manual transmission in an EV application. From the sound of it, Morgan will use the 6-speed Getrag transmission that’s normally mated to the BMW V8… but because it’s not clear how much power the +E will produce, it’s possible that another solution will be used. But the man-tran will definitely make an appearance, as Zytek’s Neil Cheeseman explains

Keeping the motor in its sweet spot will help it use energy more efficiently, which will increase the vehicle’s range. It also allows us to provide lower gearing for rapid acceleration from pull-away and higher gearing for top speed. It should also make the car more engaging for keen drivers.

EVs will make better progress with hard-core gearheads when shiftable multi-speed transmissions are made part of the package, but as Tesla has proved, engineering a reliable multi-gear EV ain’t easy. If Morgan is the first firm to bring one to market, it could radically alter the retro sportscar maker’s position in the industry.

More by Edward Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- InCogKneeToe Wow, memories. My Parents have a Cabin on a Lake, I have a Plow Truck and Friends, access to Lumps (old tired autos). What happens? Ice Racing!. The only rules were 4 cylinder, RWD only. Many Chevettes were destroyed, My Minty 1975 Acadian Hatch Auto with 62,000kms, did also. Rad, Rad Housing etc. My answer, a 1974 Corolla Hatch 4 speed, the rest of the Vettes took offence and Trashed the Yota. It was so much quicker. So rebuttal, a 1975 Celica GT Notch, 2.2L 20R, 5 Speed. Needed a New Pressure ate but once that was in, I could Lap the Vettes, and they couldn't catch me to Tag me.

- 28-Cars-Later I'm not sure when it was shot, but I noticed most shots featuring a Ford are pushing the BEV models which haven't sold well and financially kicked the wind out of them. Is it possible they still don't get it in Dearborn, despite statements made about hybrids etc.?

- ToolGuy I watched the video. Not sure those are real people.

- ToolGuy "This car does mean a lot to me, so I care more about it going to a good home than I do about the final sale price."• This is exactly what my new vehicle dealership says.

- Redapple2 4 Keys to a Safe, Modern, Prosperous Society1 Cheap Energy2 Meritocracy. The best person gets the job. Regardless.3 Free Speech. Fair and strong press.4 Law and Order. Do a crime. Get punished.One large group is damaging the above 4. The other party holds them as key. You are Iran or Zimbabwe without them.

Comments

Join the conversation

Someone explain why a rev matching algorithm with DSG-style manual transmission would not work. That seems to be the logical answer. For upshifts, the motor controller can brake the motor (regen, anyone?) to match revs with the clutch disengaged. For downshifts, juice the motor to spin it up, match revs, and let regen scrub off speed. The motor would be operating more like a servo. Seems obvious and it is baffling why no-one is trying it. What am I missing?

I'm just posting here because my name is Morgan!