TTAC Project Car: The Deeper You Go…

Most of this dialogue happened:

Brian: “My wife and kids are going on vacation somewhere I’d never go (Disney World) so that’s a good time to drive up to Dallas and work on the Sierra.”

Me: “Your family just had to pick the hottest week of the year to dump you on me, didn’t they?”

Brian: “Shut up, Sanjeev! Get over here and work on your stupid brown car!”

But I’m getting ahead of myself, as our last installment had the Sierra waiting for a (not bashed) front subframe and a higher performance 2.3-liter “Lima” accessory drive to get to the next phase. Luckily the good used subframe from Merkur Midwest dropped in perfectly, with no issues regarding the right-hand drive steering rack/shaft!

And, as previously mentioned, I went to my local LKQ Pull a Part and found the holy grail: the modular 1992-1994 Ford Ranger 2.3L serpentine assembly setup. I grabbed the alternator bits, the crank and water pump pullies, noting this also includes Ford’s 3G alternator ( big upgrade) to boot: this ensures the inclusion of an electric fan and maybe an Infinity Bass-link subwoofer (that I have lying around) in the future without repercussions.

This setup is completely modular: adding options (power steering and A/C) without changing anything but the length of the serpentine belt! None of that V-belt nonsense because you wanted power steering!

You’ll see why I wasted all this time/spilled so much digital ink with the next photo.

The low to the earth demeanor lowers the Sierra’s center of gravity (by 20-ish lbs) but, more importantly, streamlines the turbo plumbing’s path. More on that later.

The system truly shines (so to speak) after adding a remanufactured alternator and cleaning every nook in that fancy aluminum casting (after years of oil from a valve cover leak and dirt accumulation).

Once the motor bolted to its Merkur subframe, the valve cover didn’t clear the outer cowl. This motor is pushed significantly rearward in this modest body, and the Ford’s turbo-bespoke aluminum valve cover isn’t exactly slender.

And this outer cowl is a unique part for right-hand-drive designs, so the Merkur parts car was no help!

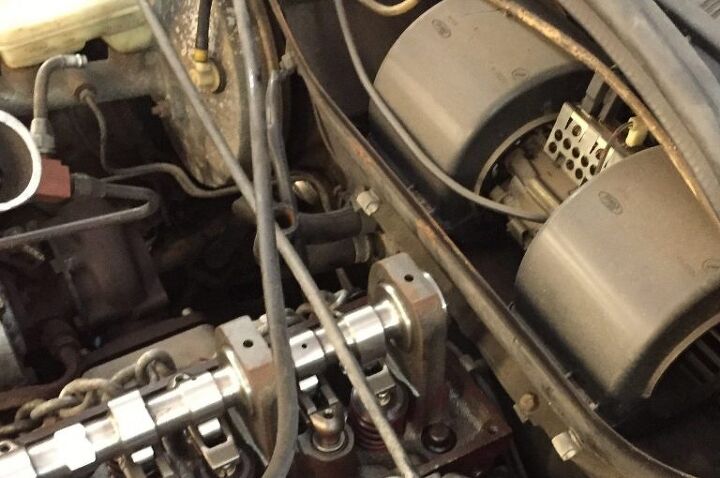

Luckily, a 1-2mm bend in the cowl had it sorted: body shaping hand tools provided the requisite clearance. But look how close the camshaft sits relative to the HVAC blower motor!

With the motor in and (mostly) assembled, it’s time to get the intake/turbo plumbing laid out.

That silver 90-degree elbow (left, sourced from a Merkur Facebook group) is the turbo’s outlet, implying this is no ordinary Ford 2.3 Turbo: the air’s now going to a front-mounted intercooler.

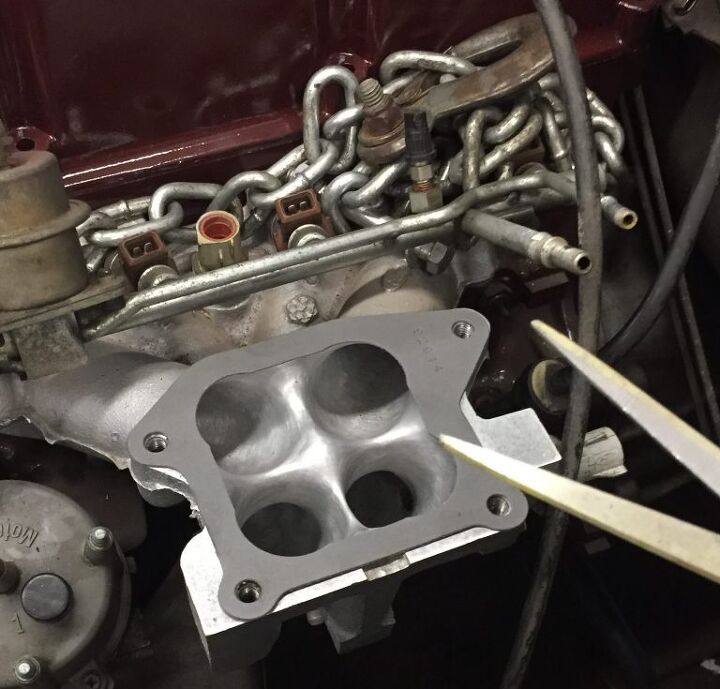

I quite love the finished product in this Steve Schlodes ported lower intake; pretty enough to necessitate a good trim to the manifold gasket!

The silver “elbow” was the ported upper intake from our Thunderbird Turbo (from an earlier update) whose previous owner ground down the cosmetic ribbing (and EFI lettering) for a look that blends nicely with the Ford Motorsport cam cover. A visit to Merkur Depot for a 90-degree rotation (including shortening to clear the hood) and an EGR delete completed the task: this rotation is possible because of the aforementioned Ranger alternator, ensuring air leaves the intercooler and enters the engine as efficiently as possible.

Repeat after me: Bends are not your Friends!

While I wanted to keep all factory emissions equipment, the EGR valve was another layer of complication in this croissant of automotive madness. I’m still doing the most important bit: adding a high-flow catalytic converter to the exhaust (eventually).

With the front of the motor sorted, it’s time to discuss the transmission. The Sierra came with Ford’s not terrible (for 1983) C3 automatic, but it’s clearly not what this high horsepower project demands. Neither was the Merkur’s sloppy, weak-kneed T-9: only a proper Borg Warner T-5, found in the Sierra Cosworth/Mustang SVO/Thunderbird Turbo, had the capacity to handle our custom cammed 2.3 Turbo.

Oh, and thanks again to fellow autojourno Zach Bowman for donating this clutch and flywheel after his Ugly Horse went full Ford Ecoboost.

Here you see the T-5 bellhousing installed, but what you can’t see is how tightly formed the 1982-84 (1985?) Sierra’s transmission tunnel is compared to later versions. The T-5 fits, but bolting to the body isn’t nearly as straightforward as Merkur T-5 google searches suggest.

Because nothing looks like what we had to make:

The end result may not be beautiful, but it’s a work of art. Within minutes, Brian made this bespoke transmission crossmember from metal scraps!

And I grabbed an SN-95 Mustang transmission mount for it.

Rubber is being used everywhere possible for factory levels of NVH control. Plastic based bushings aren’t my style, Houston’s roads are far too unforgiving, and I don’t need to feel every vibration from this ‘box.

Sometimes it pays to have friends that can see a problem, imagine the stuff in their shop coming together, and just make it happen out of sheer brilliance. That, and a lot of measuring.

It’s far from complete, but there’s another installment coming soon on TTAC’s Ford Sierra.

[Images:© 2019 Sajeev Mehta]

More by Sajeev Mehta

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Lou_BC Well, I'd be impressed if this was in a ZR2. LOL

- Lou_BC This is my shocked face 😲 Hope formatting doesn't fook this up LOL

- Lou_BC Junior? Would that be a Beta Romeo?

- Lou_BC Gotta fix that formatting problem. What a pile of bullsh!t. Are longer posts costing TTAC money? FOOK

- Lou_BC 1.Honda: 6,334,825 vehicles potentially affected2.Ford: 6,152,6143.Kia America: 3,110,4474.Chrysler: 2,732,3985.General Motors: 2,021,0336.Nissan North America: 1,804,4437.Mercedes-Benz USA: 478,1738.Volkswagen Group of America: 453,7639.BMW of North America: 340,24910.Daimler Trucks North America: 261,959

Comments

Join the conversation

Painting the brace red helped, you gained 10 HP right there.

I happen to like the T-9 five speed that came with my two XR4Ti's, but I wasn't doing what you're doing-I was just driving them as they came 'in the box', with no powertrain mods. And for those guys with a attitude towards XR4Ti's, drive one before you rag on them. If nothing else, they had the best front seats I've had in any FoMoCo ride. Last thing, one of my buddies races a Caterham 7 with a Focus SVT motor and T-9 transmission, and has had no problems with either motor or trans.