Plus a Charge: 1916 Woods Dual Power, An Early Gas/Electric Hybrid of Surprising Sophistication

Reading Alex Dykes’ review of the 2014 Honda Accord Hybrid, I was reminded of something by Alex’s description of the Accord’s drivetrain layout. Unlike the Toyota and Ford parallel hybrid systems (similar in function but arrived at independently), or the Chevy Volt’s Voltec drivetrain (a different spin, no pun intended, on the same basic idea that allows the Volt to operate mostly in pure electric or serial hybrid modes), which all connect electric motors and a gasoline engine to a planetary gearset, the Accord now uses an inline serial/parallel hybrid system, a concept that actually goes back a century to the Woods Dual Power automobile.

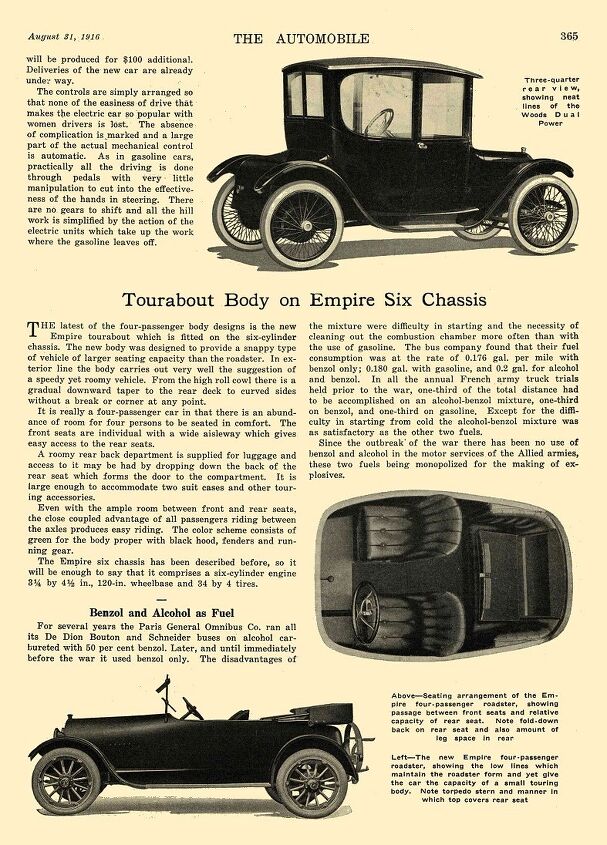

Directly connected to the engine’s output shaft of the 2014 Accord Hybrid is a motor/generator whose own output shaft is in turn connected to an electronically controlled clutch. Behind the clutch is another electric motor that drives the wheels without the use of a transmission. At low to moderate speeds, when it’s not operating on battery power alone, the Accord operates as a straight serial hybrid, like a diesel-electric locomotive. The engine drives the generator, which powers the second electric motor and there is no physical connection between the engine and the driven wheels. At higher speeds, the clutch engages and the combustion engine and motor/generator start contributing mechanical power to the system via the armature shaft of the primary drive motor. The new Accord Hybrid’s drivetrain layout reminded me of a car built almost a century ago, the 1916 Woods Dual Power. I sent Alex a link to a post I’d written about the Woods car last year for Hemmings, and when he agreed that the systems were similar I thought I’d share a description of the Woods hybrid with our readers here at TTAC. In the year or so since that was published I’ve learned more about the Woods company’s history, so this is a good opportunity to update that information.

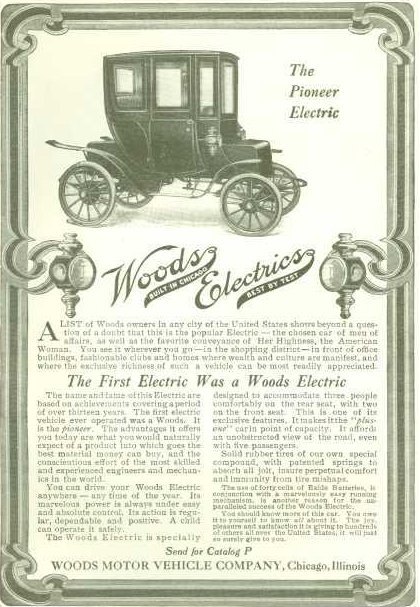

Clinton Edgar Woods, it could be said, wrote the book on electric cars, literally. Okay, so he published it in 1900 and there wasn’t as much to write about then as there is more than a 110 years later, but Woods was indeed an electric vehicle pioneer. The MIT graduate started his first electric car company, American Electric, in 1896, which two years later merged with the Indiana Bicycle company to become Waverly, a company that produced electric automobiles until 1916. In 1897, Woods started a new company under his own name in Chicago, producing five models of electric cars but the company was not profitable. A group of financiers including Chicago’s Samuel Insull, who founded Commonwealth Edison, and New Yorker August Belmont, along with a syndicate of Canadian Standard Oil investors, staged a takeover of Woods’ company to use as a vehicle to challenge the taxicab monopoly of the Electric Vehicle Company. They bought Woods’ patents and recapitalized the company at a value of $10 million, calling it the Woods Motor Vehicle Company, keeping Clinton Woods on as a consulting engineer.

Later advertising would claim that they were the first company to sell an electric automobile. Perhaps the oil interests were hedging their energy bets but in any case they were hoping to be able to use Woods’ expertise. However, after a 1901 reorganization Woods left the firm, apparently to become a car dealer.

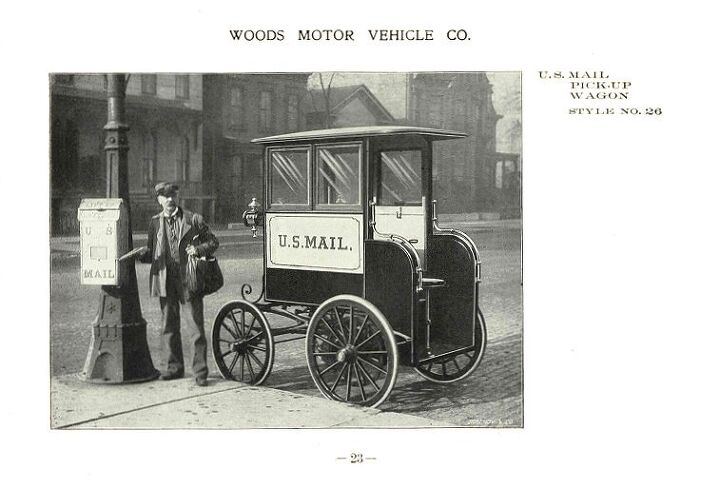

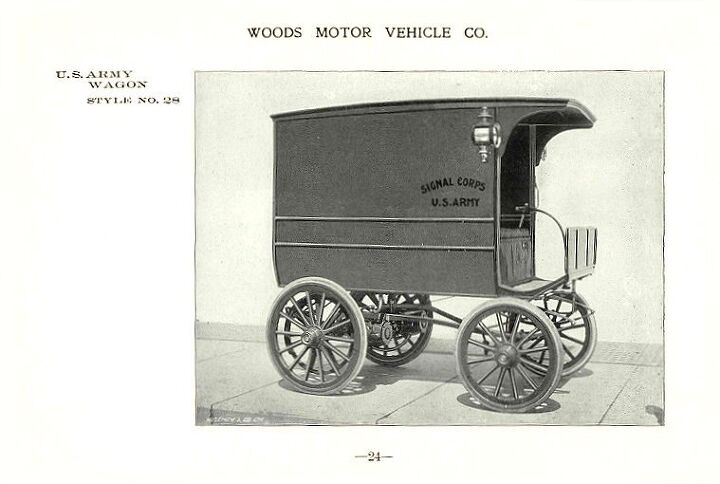

Over the course of about two decades, the company would go on to sell about 13,500 passenger and commercial vehicles, including electric cars, gasoline powered cars and gasoline/electric hybrids. Long before the federal government encouraged the development of EVs, Woods was selling electric trucks to the U.S. Postal Service and the U.S. Army Signal Corps.

That production figure would probably make Woods Motor one of the most successful electric car companies before the modern era. The last car they sold, the Woods Dual Power, may not have been a commercial success but it was a remarkably sophisticated machine whose features are echoed in many modern hybrids besides the obvious similarities in layout with the latest Accord Hybrid.

By 1915, two developments sounded the death knell for the early EV industry. First, in 1912 Cadillac introduced Charles Kettering’s electric self starter, making it possible for large numbers of women (who didn’t have the upper body strength to hand crankstart a car) to drive. Women drivers were an important, perhaps primary, market for the early electric car industry. Secondly, Henry Ford moved production of the Model T to his new Highland Park plant and in 1913 started using a moving assembly line, producing over 300,000 cars that year, significantly driving down the manufacturing cost and retail price of gasoline powered automobiles. Compared to Ford, the growing General Motors, and Studebaker, makers of electric cars and trucks were boutique manufacturers, they simply couldn’t compete with volume manufacturing.

Woods had made electric cars and they had made gasoline cars. To stay in business the company decided to make a car that used both power sources. While a technically clever idea with some marketing potential, a small volume car company making a novel car that involved the cost of both an electric drivetrain and a gasoline engine just as Mssrs. Ford and Durant were making conventional automobiles even cheaper may not have been the best strategic business move, but had they not gone with the hybrid you wouldn’t be reading this, then, would you?

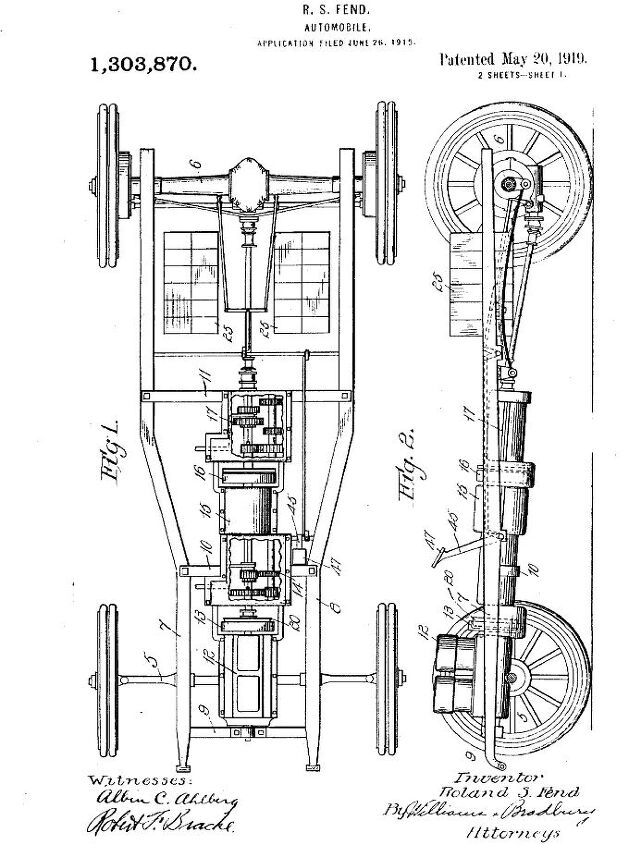

The drivetrain of the 1916 Woods Dual Power was the brainchild of another inventor named Roland S. Fend. Though there are differences, the Woods production cars were based on a patent of Fend’s that was assigned to the company. Fend was an acknowledged expert on EVs in his day, also consulting for early EV maker Baker, Rauch & Lang

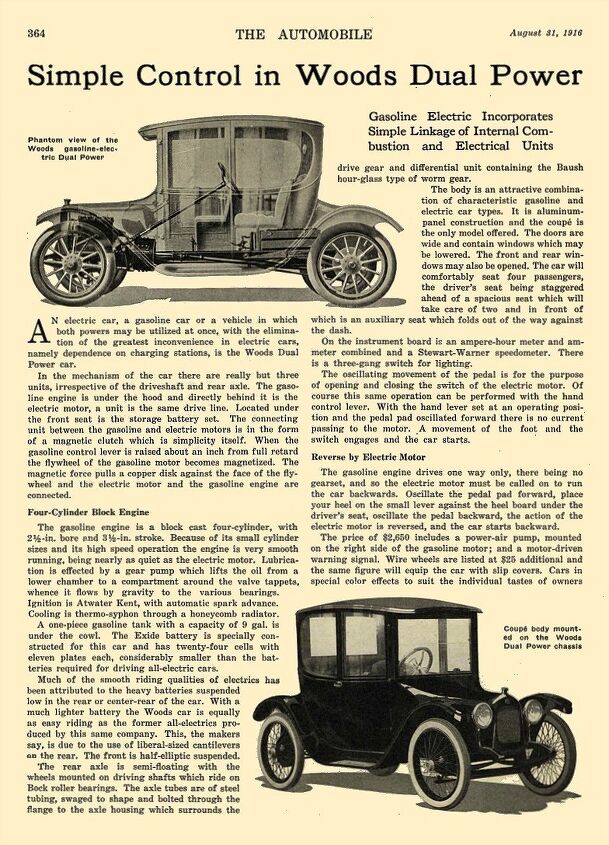

Advertised as “a self-charging, non-stalling, two-power car with unlimited mileage [range], adequate speed, and greatest economy,” the Dual Power was said to have the advantages of both gas and electric power, with the disadvantages of neither. It was faster than most other electric cars, it was easier to operate than gasoline cars, it had no clutch or gear selectors, and it didn’t necessarily need a charging station. The Dual Power even had a great logo, though in an age when some still called automobiles horseless carriages, it surprisingly used a team of two identical horses to represent the two different power sources. It’s a fantastic period logo, but it’s still a little odd.

The concept behind the Dual Power hybrid was that gasoline powered cars, in order to have reserve power for passing or hill climbing, had to be equipped with engines that are bigger and more powerful than needed in regular driving. Electric cars needed to carry around heavy extra batteries for reserve power. Fend’s idea was that the combination of a less powerful gasoline engine and an electric drive with a smaller motor and fewer batteries would be a greater whole than the sum of its parts. Each power source could propel the car at low to moderate speeds, while they could be combined when more power was needed.

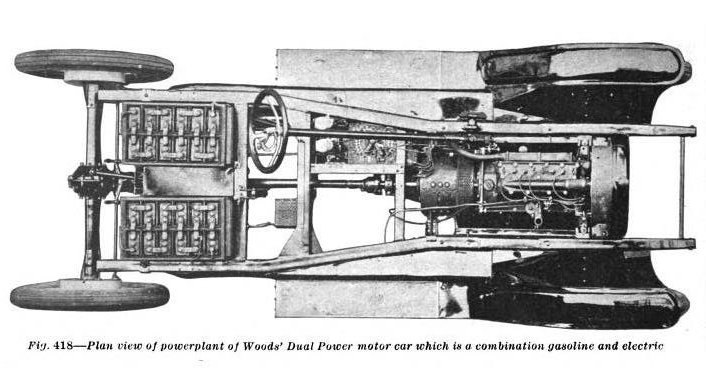

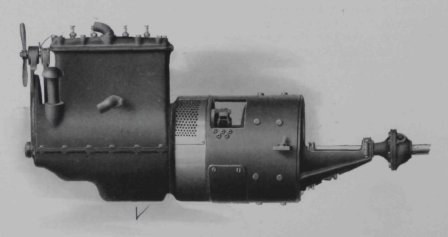

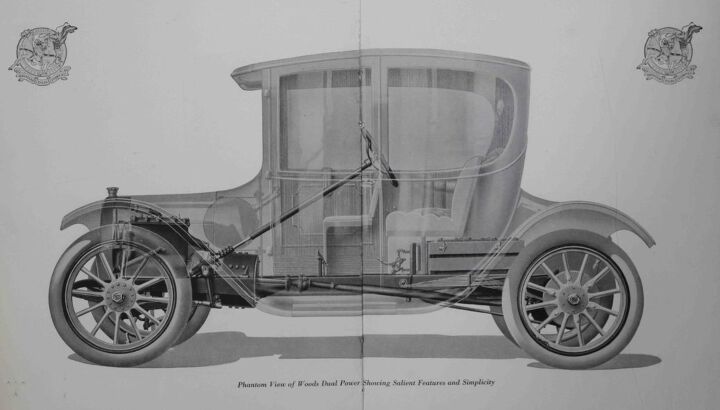

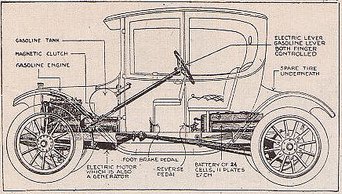

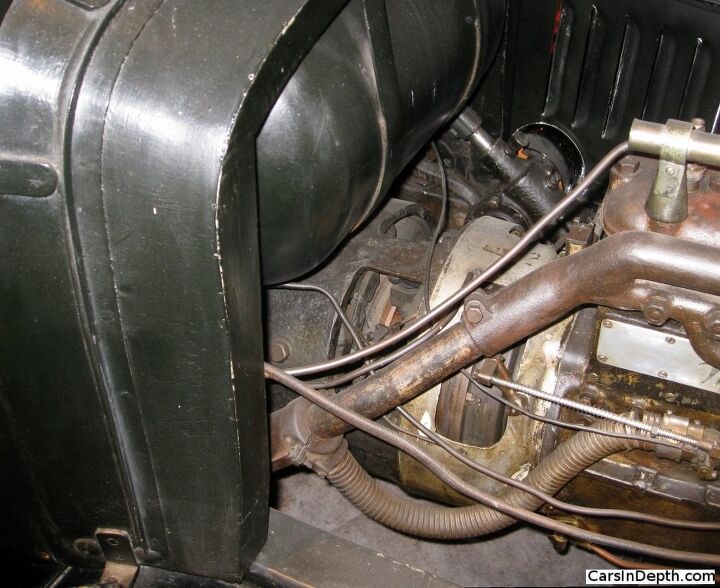

The Dual Power has a 14 horsepower, 68.7 cubic inch L-head four cylinder engine supplied by Continental. It was connected to a compound-wound electric motor. Woods Motor called it a dynamotor, what we would call a motor/generator. DC compound motors have both series and parallel (also known as shunt) windings, providing adequate starting torque while still allowing accurate speed control. It was made by General Electric and rated at 48 volts at 60 amps (~6 horsepower). The electric motor was connected to the output shaft of the engine with an electromagnetic clutch manufactured by Cutler-Hammer. A battery pack made of purpose built lead acid cells supplied by Exide was rated at 115 amp-hours at a five hour discharge rate. It was about half of the size and weight of the battery packs used by conventional EVs then. The output shaft of the electric motor was connected to a driveshaft running to the back axle. While Fend’s patent shows gearboxes in the power chain before and after the electric motor, the Woods Dual Power had no transmission. The layout in Fend’s patent with gearing before and after the electric motor is similar to GM’s recently aborted 2-Mode hybrid. It also didn’t have an Entz magnetic transmission, as used in the Owens Magnetic car from the same era, even though Wikipedia says it did. That error may be attributable to the fact that the Owens Magnetic is better known than the Woods Dual Power because well known car collector Jay Leno owns an Owens Magnetic.

There are three and a half Woods Dual Powers known to exist. The half car, coincidentally is a Woods body mounted to the chassis of another early alternative energy vehicle, a Stanley Steamer (though in the early days, electricity and gasoline were actually alternatives to steam engines). One complete Woods car, the subject of a preservation project, is owned by a Los Angeles county museum and is on loan, displayed at the Petersen Museum. Another, said to be restored and in operating condition, is owned by the Louwman Museum in the Netherlands. The Woods Dual Power photographed here is in the collection of the Henry Ford Museum, in original, unrestored condition, with just 11,085 miles on the odometer, though the car is not currently operational.

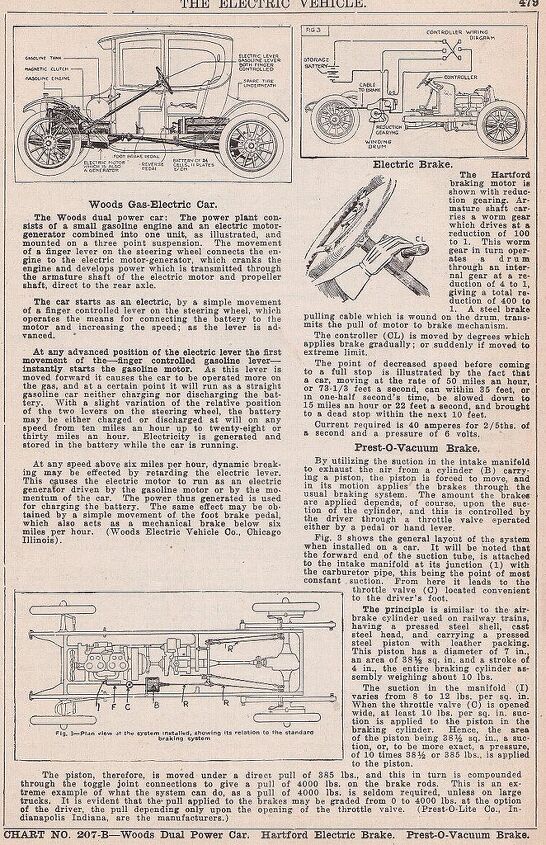

When it was operational, how did the Woods Dual Power work? With the clutch engaged, the combustion engine would drive the car, with torque passing directly through he electric motor’s armature shaft. With the clutch disengaged and the engine not running, the electric motor powers the car. That much was clear.

Finding out exactly how the Woods Dual Power worked, though, was a bit of a task. To begin with, with only three existing Woods powertrains, it’s not like you can find an expert on the marque at any big car show. It’s not a 1969 Camaro, or even an Isetta. Fortunately, I was able to find a sales brochure (PDF), a period guide to automotive electrical equipment for car enthusiasts, and some old trade journals that explained how the Dual Power worked and how it was operated.

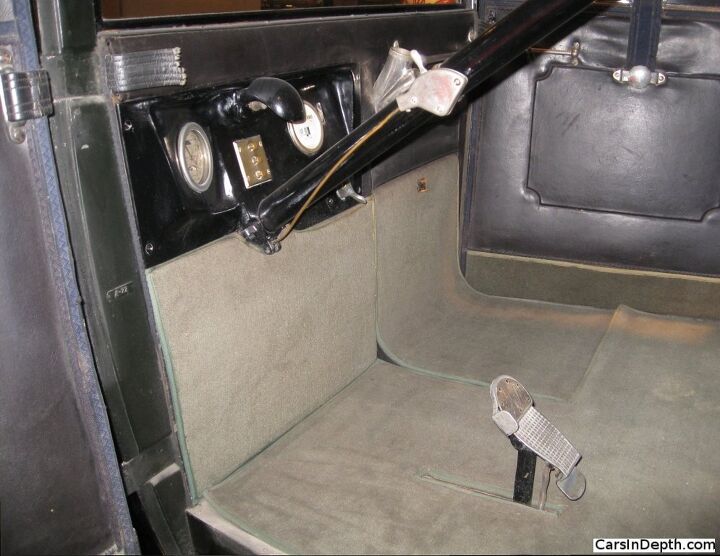

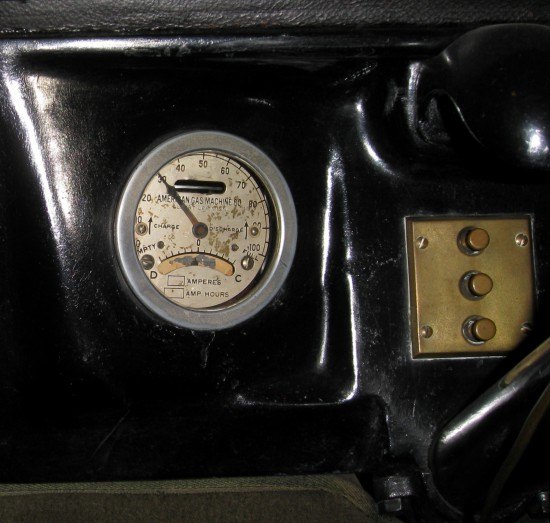

Matt Anderson, the transportation curator of the Ford Museum, graciously gave me access to their car, a 1916 Woods Dual Power Model 44, for these photos. It has simple controls: a steering wheel mounted with long and short control levers, one for each of the powerplants, a brake pedal on the floorboard, and a backup pedal below where the driver sits. The dashboard contains a Stewart Warner “magnetic type” speedometer/odometer/trip meter along with a combination ammeter and charge indicator.

To operate the Dual Power, first an ignition switch on the steering column is turned on. The sources say that it’s a locking switch though the example at the Henry Ford Museum doesn’t use a key. That switch closes electrical connections in both the combustion engine’s ignition circuit and part of the circuit for the main solenoid that’s between the traction batteries and the electric motor. For safety, all high-voltage switching was done with solenoids. The longer of the two levers on the steering wheel is moved forward. That completes the main solenoid circuit, allowing electricity to power the motor, getting the car moving. Moving the lever farther forward changes the position on a shunt field control rheostat near the motor under the floorboard and as the field resistance on the motor changes, the speed increases. Moving the lever back towards its idle position decreases speed.

Once the Woods Dual Power was moving, the gasoline engine could be engaged at any time. Electric drive was generally used up to about 15 MPH. If more power was needed, just moving the shorter lever on the steering wheel to a forward position would start up the gasoline engine. That lever controlled the throttle on the carburetor. Also, moving it off the stop activated a circuit that engaged the magnetic clutch between the engine and the motor. Electricity to activate the clutch was provided either by the battery or by the motor/generator when the car was running on gasoline power.

Since the ignition circuit on the Dual Power is activated when the car is first switched on, with the relatively powerful electric traction motor already rapidly spinning, the engine on the Woods Dual Power was claimed to fire up immediately as soon as the clutch was engaged, faster than with the much weaker electric starters on conventional cars of the day. I suppose this feature would be comparable in some ways to a modern stop-start system, starting the engine when needed and shutting it off when the car was standing still. The company also claimed that the Dual Power could not be stalled. Whenever the combustion engine was driving the car, the electric motor was already spinning at engine speed even if it wasn’t energized. If the engine started to stall, power could be sent to the electric motor to assist the engine by just moving the control lever forward.

The best selling electric cars then were made by Detroit Electric and had a top speed of 20 miles per hour. With both control levers all the way forward, the Woods Dual Power had a top speed of 35 MPH, a significant improvement.

Once the car was moving forward, the gasoline engine had enough power and torque to keep it going at moderate speeds and the control lever for the electric part of the hybrid could be adjusted so that the electric motor was no longer driving the car. In those conditions, the “dynamotor” was generating more current than it was drawing, so the Woods Dual Power could theoretically recharge its own batteries while it traveled. In that aspect, the Woods Dual Power is like the extended range Chevy Volt.

Once the gasoline engine was running, the electrical system could be charged or discharged “at will” at any speed between 10 MPH and about 30 MPH, or at least that’s what the company claimed. Keeping the batteries moderately charged by the gasoline engine also extended battery life by preventing the gassing and sulphating caused by overcharging or fully depleting the charge. One could say that this was an early version of battery conditioning, an important feature of most modern electric vehicles.

Another feature of modern EVs that the Dual Power had was regenerative braking, what the company called “dynamic braking”. To slow the car, the driver would return the electric control lever to its original position, allowing the motor/generator to generate electricity and slow the car as the motor was spun by the car’s forward motion. If engine braking was needed or desired, the driver throttled back the engine with its control lever but kept the clutch engaged, then returned the engine control to it’s stop, disengaging the clutch and shutting off the engine as the car came to a full stop.

Regenerative braking was advertised as working above 6 miles per hour. To come to a complete stop the car’s mechanical brakes were activated with a foot pedal. An interesting safety feature of the car was that if the driver didn’t want to use the hand controls to slow the car, or more importantly if they didn’t have time, the brake pedal could be used by itself instead. In addition to activating the mechanical brakes, the floor pedal also closed the gasoline throttle, disengaged the clutch, and returned the field control rheostat to its minimum position, initiating regenerative braking. According to one source, the foot pedal could also be used to control the speed of the motor when operating on electricity. As with other early electric cars, advertising for the Woods Dual Power emphasized how women would find it easy to operate.

Since there was no transmission, to go backwards, the polarity of the power to the direct current electric motor was flipped so the motor spun backwards. There was also an interlock device that would not allow the operation of the reverse pedal unless the brake pedal was fully depressed. Stepping on the reversing pedal also disengages the magnetic clutch, allowing the gasoline engine to continue to run while the Dual Power is reversing.

In a recent post I asked, if General Motors’ 2-Mode hybrid system for pickups and SUVs worked so well at saving fuel, how did it fail at the market, discontinued in the next product cycle? Well, just like the 2-Mode vehicles, the Woods Dual Power was relatively expensive, $2,650 in 1916 dollars. While much cheaper than the $9,000 Owens Magnetic, in 1916 you could buy almost four Ford Model Ts for the price of one Woods Dual Power. The Woods hybrid returned gas mileage that would be remarkable today, a reported 48 MPG, but economy generally has never been a big selling point with people who can afford expensive cars.

Another reason why it didn’t succeed was that the Dual Power was not as smooth, nor as reliable as advertised. For the 1917 model year, there was some reengineering in response to customer dissatisfaction, including using a larger, 95 cubic inch engine from Continental. Though faster than other electrics, the Dual Power could easily be overtaken by the far less expensive Model T, which could cruise at 40 mph, 45 if the driver was brave or stupid.

Maybe an even bigger engine or a more powerful electric drive would have made the Woods Dual Power more competitive with conventional cars. Being superior to electric cars at a time when the first generation of EVs were already in decline as the technology of gasoline engines improved and the cost of gasoline powered cars declined was not good enough. Though they planned to make between 650 and 750 Dual Power cars a year, a fraction of that number was made and Woods Motor Vehicle Company went out of business two years after introducing the hybrid.

Still, the Woods Dual Power had features associated with modern hybrids and extended range hybrids like regenerative braking, stop-start, charging on the fly, and battery conditioning. It was an elegant, well thought out design whose simple operating controls belied the complexity of the electrical components, solenoids and mechanical linkages that actually operated and coordinated the machinery, gas and electric. While it may not have been superior to the conventional automobiles of the era, the Woods Dual Power’s hybrid drive system in fact did work. That Woods Motor Vehicle Co. was able to get it to do so 100 years ago, using solenoids and mechanical linkages rather than digital computer controls, was an impressive technical achievement and worthy of inclusion in a world class car museum like The Henry Ford. In that recent post about another hybrid system, the 2-Mode transmission now abandoned by its inventor, General Motors, and GM’s partners in developing the technology, Daimler, Chrysler and BMW, I said that you never know, sometime in the next century the 2-Mode system might return on passenger vehicles (the Allison truck and bus transmission the 2-Mode is based upon has been a commercial success). Perhaps 100 years from now, someone will introduce some kind of transportation device and an older person will ask a similar question as I did, “Doesn’t that operate a lot like the Accord hybrid?” and someone even older will chime in, “Or the Woods Dual Power.”

In the 1980s, General Motors tried saving fuel through cylinder deactivation. It was a pretty high tech thing and and befitting as such, GM introduced it on a Cadillac engine called the V8-6-4. Today, cylinder deactivation is commonplace across the industry and it works pretty much seamlessly. Back then, control and actuation devices weren’t so good. Cadillac buyers ended up with rather rough running engines, something that badly damaged the brand for decades, though the V8-6-4 was available for just one model year. Old ideas are indeed sometimes a bit early for their times and worth a second look when materials science and technology improve.

I’d be intrigued what would happen if someone made a modern replica of the Dual Power drivetrain. The Accord Hybrid is similar, no doubt, but it also includes a second electric motor that normally operates as a generator. The Woods car has only one motor/generator. It would be interesting to see how something directly analogous to the Woods Dual Power would work. Maybe use one of the turbocharged 3 cylinder liter motors that are proliferating in the automotive world, connected via a clutch to something smaller than the traction motor in the Tesla Model S, with a correspondingly smaller and lighter lithium-ion battery pack. Control it with a computer just like modern hybrids are controlled so you just have to step on the gas and brake pedals, not fiddle with steering wheel mounted controls, and so the batteries are maintained in a healthy state of charge without the driver’s attention needed. It might not be as quick as a Model S, but I bet it could move a compact or midsize car around safely in traffic, maybe even smartly. It would be interesting to see how it would stack up in terms of fuel and electricity consumption and range with modern hybrid designs.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can get a parallax view at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks for reading – RJS

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- ToolGuy If these guys opened a hotel outside Cincinnati I would go there to sleep, and to dream.

- ToolGuy Michelin's price increases mean that my relationship with them as a customer is not sustainable. 🙁

- Kwik_Shift_Pro4X I wonder if Fiat would pull off old world Italian charm full of well intentioned stereotypes.

- Chelsea I actually used to work for this guy

- SaulTigh Saw my first Cybertruck last weekend. Looked like a kit car...not an even panel to be seen.

Comments

Join the conversation

Just read that it has an aluminum body to boot. Everything that's old is new again.

Thanks for posting this!