Toyota Gas Pedal Fix Explained – With Exclusive Photos

Update: A portal to all of TTAC’s related articles on Toyota gas pedals is here:

Toyota has released their official “fix” for the sticky CTS-made gas pedals on the recalled models affected. From their graphic, it’s difficult to understand what parts are involved, and how they work. Thanks to our recent tear-down of the CTS pedal, we have the pictures and familiarity with the unit to explain it in detail.

The pedal is designed to have a certain amount of friction or hysteresis built in. This is done so that the fatigue of pressing the pedal continually is not onerous or becomes fatiguing. It also replicates the friction that would normally be present in a conventional throttle cable as it passes through its housing. A throttle assembly without the correct amount of friction or hysteresis would be very difficult to control smoothly.

Obviously, the exact amount of friction designed into the unit is very critical, so that the pedal returns as soon as the pressure is removed or reduced. The relationship of the spring pressure and built in friction must be stable and consistent. Toyota has stated that that is not always the case with the recalled CTS units, and that the degree of friction can increase over time due to wear and/or condensation, to the extent that the friction is greater than the pressure from the return spring. This would potentially cause a gas pedal to return slowly, unevenly, or not at all from the point where it was released.

This problem would not be the cause of “unintended acceleration” to the extent that the pedal would only stay open as much as it was before being released, although it could well be experienced as such. If the car was being accelerated briskly as on an on-ramp or hill, and the pedal stuck in that degree of openness, the car could well feel like it was accelerating on its own after the target speed was attained and the foot pressure reduced.

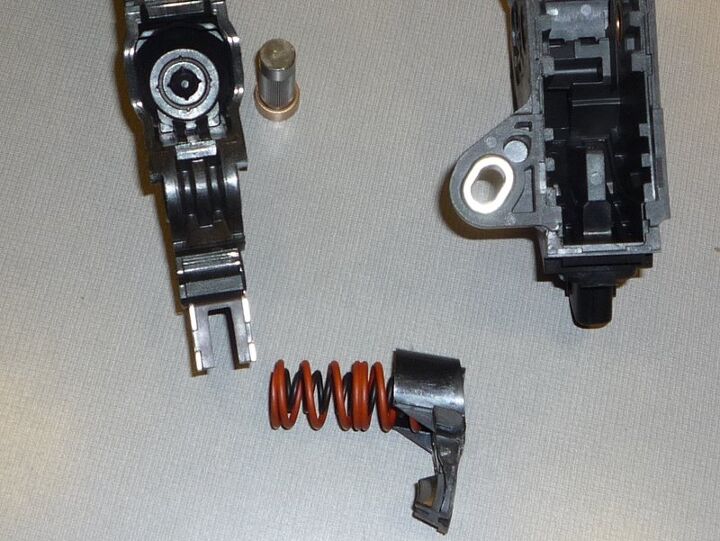

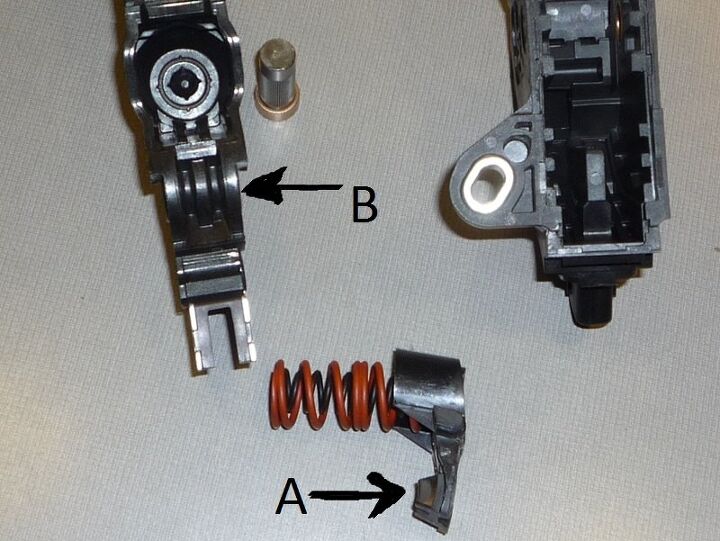

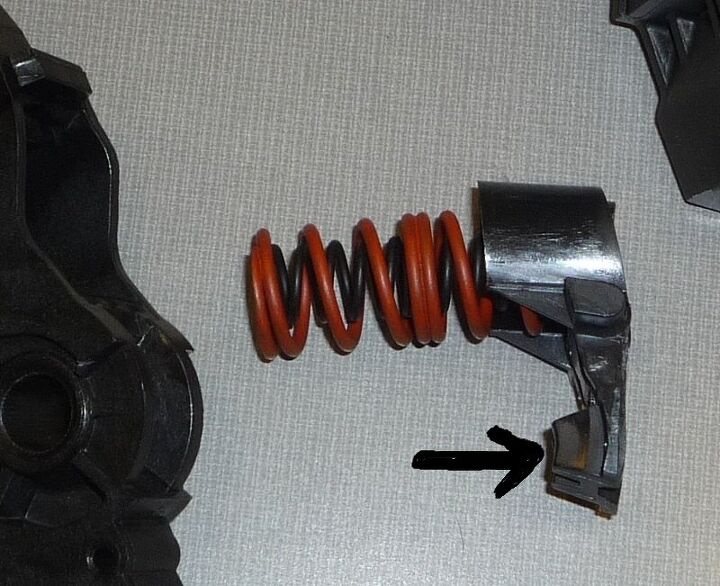

The affected part is in the lower center of the photo above (A), and in more detail in the one below. It is integral to the part that retains the return spring. The friction area is seen as the small “teeth” or “ears” protruding to the left at the very bottom of the picture. These two teeth ride in the two grooves of the pedal assembly (B), and are held against each other when the spring assembly is locked into position. The area of friction is seen as the grayish worn area on the teeth just beyond of the (crude) arrow.

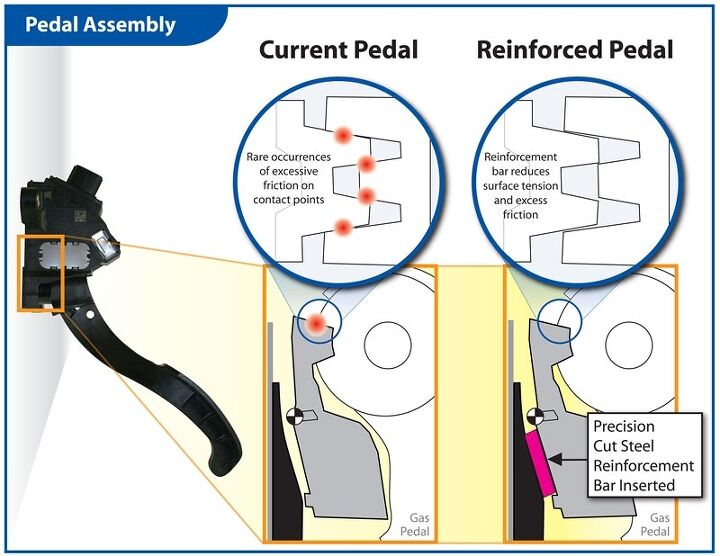

From Toyota’s graphic (below) and from my experience handling the unit, it appears that there is a certain amount of free play of the spring retainer/friction block unit. In Toyota’s graphic below, it shows that unit tilting slightly, perhaps due to too much free play or wear of the plastic components. The steel reinforcement bar (red unit below) is apparently intended to stabilize the angle of the spring retainer/friction block unit, to ensure that the degree of friction is either more consistent or is compensated for the wear that has occurred.

We intend to secure a pedal unit and the steel reinforcement bar as soon as they are available for further examination and evaluation.

Update: see follow-up story on replicating the “fix” here. And the final piece comparing the Denso with the CTS unit, and our conclusion and recommendation is here.

More by Paul Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- NotMyCircusNotMyMonkeys so many people here fellating musks fat sack, or hodling the baggies for TSLA. which are you?

- Kwik_Shift_Pro4X Canadians are able to win?

- Doc423 More over-priced, unreliable garbage from Mini Cooper/BMW.

- Tsarcasm Chevron Techron and Lubri-Moly Jectron are the only ones that have a lot of Polyether Amine (PEA) in them.

- Tassos OK Corey. I went and saw the photos again. Besides the fins, one thing I did not like on one of the models (I bet it was the 59) was the windshield, which looked bent (although I would bet its designer thought it was so cool at the time). Besides the too loud fins. The 58 was better.

Comments

Join the conversation

Guys, if the throttle pedal sticks there is a simple remedy: shift to neutral, or turn the power key off. It is that simple! I drive both a Camry and Lexus with this kind of pedal, and they never sticked. Looks like car corporations' games.

My daughter took her 2009 Camry in to the dealer today for the Gas Pedal recall, and were very suprised and dissapointed with the "fix" that Toyota has chosen for this problem. We picked the car up, getting the keys and a copy of the repair order from the cashier. We were not told about any precautions to take or be aware of changes in the operation of the car. The Repair order indicated that the cars computer was reprogrammed, and some work was done on the gas pedal. I asked her to test drive the car in the dealers parking lot before she went home, to check for any problems. There were 2 issues she found unacceptable, that I want to talk about here. First, she said the feel of the accelerator had changed greatly, that it took very little foot pressure to move the pedal, that it felt very light and that she was startled when she pulled out from the parking space at how fast the car jerked forward. It seems that the fix reduced the force needed to move the accelerator greatly, and she had not expected the change, and it would take some time to get used to. Secondly, the other part of the fix was to "chew off" the bottom of the gas pedal, reducing its length to about 4 inches. I say "chewed off" because the cut was very sloppy, looking like a racoon has eaten the bottom end of the pedal off. It appears that they did not replace the floor mat, as it looked like that same 10 month old mat. After calling both conditions to the attention of the service manager, he acted like we were the only one of "thousands" to complain about the recall fix. . We did NOT get acknowledgement from him that we should have been informed about the change in pedal pressure, and that an unsuspecting person might have an accident because of this change. As for the gas pedal fix, he said that "we only do what is dictated to us by Toyota." I asked if the cutting of the pedal was an interium fix, or the final fix, and did he agree with me that the gas pedal cutting was a sloppy fix for a $25,000 car ? His reply was to repeat that "this is what the factory has told us to do." This service manager did not know if this was the final fix.. At a minimum, we should have been warned that there would be a change in the pressure required to depress that gas pedal, and to be careful when first driving the car. I also feel that the removal of bottom part of the gas pedal was done very sloppy, and did not conform to any quality standard in todays manufacturing world. I am sure that Toyota would not ship a new Camry with a "chewed off" gas pedal, and that this "fix" was a "cheap way out" If we are now safer in our Toyota Camry because of this recall, a "chewed off" gas pedal might seem like a petty complaint, and would be acceptable as an interium countermeasure. If this is the final solution, then the "sloppy" nature of the fix makes me wonder where else is Toyota being "sloppy"