#ProductionTargets

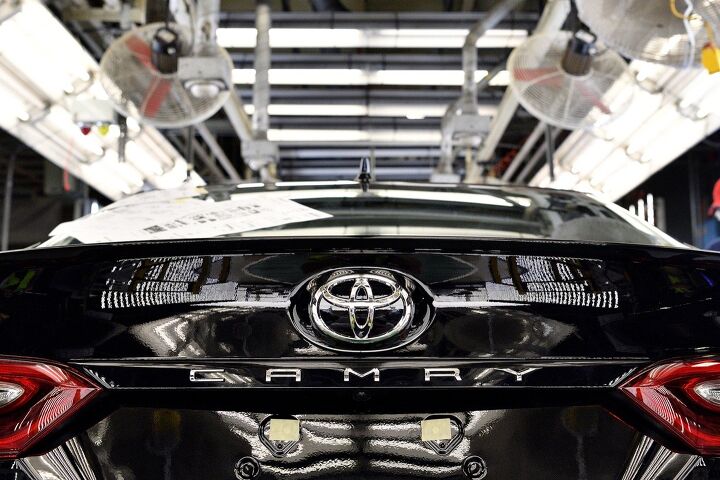

Toyota Scales Back June Production, Ford Drops German Factory

Despite starting 2022 announcing a plan to normalize output, Toyota has had trouble living up to its promise. While most automakers were figuring out how to make more money off diminished production, the Japanese brand was plotting assembly schedules that would restore assembly rates to levels that would have been considered normal prior to 2020. But the rest of the market hasn’t managed to match Toyota’s optimism and the automaker has had to scale back its global production plan yet again — citing the usual supply chain constraints stemming from COVID restrictions and worldwide deficit of semiconductors.

Meanwhile, Ford Motor Co. looks to be abandoning its vehicle assembly plant in Saarlouis, Germany. The facility produces the Focus for Europe and may be in danger of closing if the automaker elects to sell it. While the site was in the running to produce Ford’s next-gen electric vehicles, those products have since been slated for assembly in Valencia, Spain.

Chinese Lockdowns Force Toyota to Cut Production Again

The automotive industry has basically resigned itself to running with lessened production for the foreseeable future. A significant number of automakers have suggested that it might be more lucrative to scale back output, reduce overhead, and focus on achieving broader margins per car during this prolonged period of economic and logistical duress. However, Toyota started the year saying it would do its utmost to raise production output as a way to make up for losses incurred during the pandemic. The company even said it anticipated things to gradually normalize through the spring.

Unfortunately, things have not gone according to plan. By March, the Japanese automaker had lowered its output goal for the fiscal year by 500,000 global units. Another 20 percent was lopped off for the month of April and leadership began expressing concerns that those preexisting goals might be totally untenable. While there were moments with the target actually rose, Toyota has repeatedly been forced to walk those claims back as the realities of the market dashed its dreams. Now, the company is once again cutting planned output for the month of June over supply chain issues with China.

Will Toyota's Production Pause Go Global?

Following last week’s announcement where Toyota explained its need to scale back Japanese production by 20 percent this April, the automaker has outlined planned slowdowns for the foreseeable future. It’s citing all the usual problems. Countries are still employing various COVID-19 restrictions that are upending supply chains, semiconductor production for automobiles remains insufficient, and there’s a war in Eastern Europe that’s creating all-new troubles while exacerbating some of the more familiar ones. But scaling back output might not be the death sentence it sounds like.

With last year resulting in 10 million deliveries worldwide, Toyota actually managed to improve its sales against 2020’s year-over-year global production decline of 12 percent. And the last two years have also yielded enhanced profitability for the automaker, despite it having expressed repeated concerns about procuring enough components to keep popular models (like the RAV4) in stock. In 2021, Toyota saw $249.4 billion in revenue and even became the best-selling automaker in the United States, dethroning former top-dawg General Motors.

Toyota Cutting Production By 20 Percent Next Month

Earlier this week, we covered Toyota stressing over the feasibility of its current production plans. Automakers around the world are presently trying to suss out how to maintain solid profitability with diminished output, with Japan’s largest manufacturer suggesting the present state of the world might force it to do likewise.

While we assumed the resulting decisions would take a couple of weeks for Toyota to finalize, as it considered its many options, the company announced on Friday that it would need to cut domestic production by 20 percent for the month of April. The automaker framed this as part of its preexisting “recovery plan” necessary to account for supply chain issues that never seem to end, saying that diminished output would gradually normalize in Japan over the spring.

Toyota Considers New Production Strategy As World Burns

Toyota Motor Corp. is reconsidering its existing production strategy, citing ongoing global issues that are hindering its ability to manufacture vehicles at a normal pace.

Like most other automakers, Toyota has endured COVID restrictions, supply chains bottlenecks, component shortages, at least one cyberattack, and some new obstacles stemming from Russia’s invasion of Ukraine. These issues have already encouraged General Motors to pursue lower output as it focuses on selling on higher-margin vehicles. Though it’s hardly the only automaker signaling diminished production for 2022. Even the National Automobile Dealers Association is assuming 2022 will be another year of extra-tight inventories and wild markups. It’s something the industry was already doing, with Toyota becoming the next company opting to rejigger its targets to account for hard times.

Musk Opens Up Over Model 3 Progress, Television Cameras Enter Fremont Facility

Tesla Motors is months behind schedule. Despite promises that Model 3 production would be humming along by the end of last year, the automaker has found itself bogged down by all kinds of delays. In March, the company’s problems were exacerbated by a voluntarily recall on 123,000 Model S sedans and another high-profile crash involving its Autopilot system.

This has shaken investors’ previously unwavering faith in Tesla, and forced a significant dip in its overall share price. Last month, the company’s stock valuation took a hit that it’s just now starting to come back from. But Tesla CEO Elon Musk knows he cannot simply dazzle shareholders with new ideas and promises, and has been camping out at the factory in Fremont, California, to prove his resolve and engage in some on-sight troubleshooting.

While he has mentioned his office sleeping-bag before, we actually got to see it in a recent interview he had with CBS This Morning host Gayle King — along with the rest of the factory. Musk invited CBS to come and see the plant and discuss Tesla’s current status, providing a rare glimpse of the facility. Normally, the automaker is incredibly strict in terms of who it allows inside and no network television crew has ever been able to film the assembly process.

Hitting the Ramp: Tesla Misses First-quarter Model 3 Production Target

You’ve probably heard of the Ford Model T before — perhaps in a book or on Tumblr or something. Brainchild of auto pioneer Henry Ford, the Model T (introduced in late 1908) revolutionized the use of the assembly line for mass production five years later. Between 1912 and 1917, annual Model T production soared from 68,711 vehicles to 735,020.

Why am I mentioning a car that’s over a century old? Well, it’s because Tesla, in all of its its exuberance, decided to namedrop the Model T in its first-quarter 2018 production report. Apparently, we might be looking at the next one.

Of the 34,494 Tesla vehicles built in Fremont, California over the first three months of 2018, some 9,766 were Model 3s. In the fourth quarter of 2017, Tesla built 2,425 Model 3s. However, Tesla claims some 2,020 of the compact electric sedans came to be in the last seven days, meaning roughly one-fifth of its Model 3 output came during an eleventh-hour, all-stops-pulled production push at Fremont — which reportedly saw volunteers from other model lines switch over to Model 3 assembly.

Bad News for Tesla: Another Autopilot Crash and a Missed Production Target

A rollover crash on the Pennsylvania Turnpike doesn’t generate many headlines, unless it’s a Tesla Model X operating in Autopilot mode.

After last week’s revelation of a fatal May crash involving Autopilot, another incident involving the semi-autonomous technology is the last thing the automaker needs, but that’s what happened on July 1, according to the Detroit Free Press.

A Model X owned by Southfield, Michigan art dealer Albert Scaglione crashed outside of Bedford, Pennsylvania, about halfway between Pittsburgh and Harrisburg. The vehicle, which the owner said was in Autopilot mode, left its lane, hit the guardrail, rebounded across both lanes and overturned after striking the concrete median.

Neither the owner or his son-in-law were seriously hurt in the crash.

Tesla, Free of Model X Production Constipation, Hits 100,000 Unit Annual Production Rate

The stuck cork that was the Model X has finally cleared its supply hurdles, causing Tesla production to hit a new high at the automaker’s Fremont, California factory.

With assembly of that model speeded up, Tesla recently hit a production rate of 2,000 vehicle per week, a knowledgeable source told Electrek — a figure that’s still way off the company’s goal of building half a million units per year within the next 18 months or so.

Musk Cracks the Whip on Tesla Production, Experts Say 'Get Real'

Everyone and their 90-year-old great aunt knows that Tesla is putting all of its might into reaching a volume target of 500,000 vehicles in 2018, but more voices are now calling CEO Elon Musk’s timeline impossible.

Musk wants high-volume production to start in less than two years, but suppliers tell Reuters that the accelerated target is a pipe dream. Will delays in parts sourcing and other nitty-gritty issues throw cold water on Tesla’s plans (and customers’ Model 3 ownership dreams)?

Recent Comments