Ford Wants Far Less Metal in Its Cylinder Heads

Iron or aluminum? For cylinder head construction, that’s the basic menu we’ve long grown used to. There’s advantages and drawbacks to both. Aluminum is lighter, but more prone to warping. Iron is stronger but heavier, with low thermal conductivity. Both materials are prone to the ups and downs of the commodities market, frustrating beancounters working at automakers everywhere.

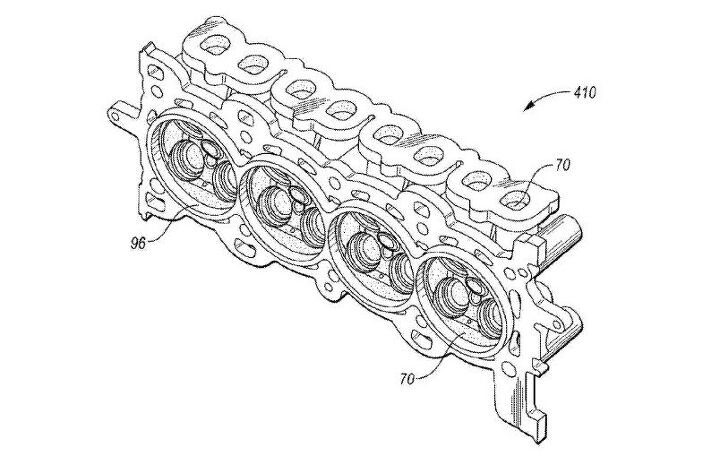

In a U.S. patent application filed in October and published today, Ford Motor Company’s global tech division proposes something new: a cylinder head containing a barest minimum of metal. Called the Hybrid Composite Cylinder Head, most of the component’s bulk is made up of polymer composite, not aluminum or iron.

Ford Global Technologies LLC points out that partial ceramic or fiber-reinforced ceramic composites have been proposed in cylinder head construction before, but both suffer from major drawbacks in withstanding high heat and pressure. Nor can ceramic be molded around a metal skeleton. With its mind on efficiency (soaring aluminum prices hammered Ford’s bottom line in 2017), the automaker took a different approach.

The proposed head features an internal metal structure surrounded by a polymer composite structure, one which may be fiber reinforced. The metal structure, made of cast iron, could include upper combustion chambers, combustion chamber inserts, fire deck, engine coolant ports, and oil drain ports. Meanwhile, the polyment structure gets some holes of its own. The patent claims the surrounding structure could include intake or exhaust oil feeds for a hydraulic lash adjuster, plus spark plug and direct injection pockets.

Any number of resins, or a combination thereof, could make up the polymer composite structure, with silicone or some kind of fiber being another possible ingredient. Ford’s clearly not ruling much out in this patent.

What the automaker hopes to achieve is a cylinder head that’s light, durable, corrosion-resistant, and far less costly to build than existing components. An added benefit from the reduced weight would be a tiny increase in fuel efficiency. The patent states that the head could find a home on a direct-injected gasoline engine or a port-injected gas or diesel engine.

As lightweight, high-strength carbon fiber slowly begins finding its way into cars, it’s not surprising to see Ford look at metal alternatives for its engine components. Two years ago, the automaker showed off a 1.0-liter EcoBoost engine at the Detroit auto show that made use of injection-molded carbon fiber for a number of parts, including the cylinder head. The mill’s weight fell nearly 16 percent compared to a stock motor.

Last year, Ford and Magna teamed up to develop a carbon fiber-reinforced composite subframe. This key piece of architecture weighed 34 percent less than a conventional subframe, employing far fewer parts.

H/T to Bozi Tatarevic!

[Image: United States Patent and Trademark Office]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- The Oracle Geesh, Stellantis can’t even perform the upkeep on that relic of a plant. Sad.

- The Oracle I see Tesla introducing disruptive charging technology within 3 years.

- The Oracle I can see into the future and I see fisticuffs and profanity-laced tirades coming to charging locations near ya’ll.

- El scotto Will ascots be discussed at the HOA meetings? Or Purdey shotguns?

- El scotto Wait, wait will they rename the street it fronts Jermyn or New Bond Street?

Comments

Join the conversation

What could possible go wrong?

The Brits wanted to make an aircraft carrier out of ice and sawdust during WWII. Ford could use that technology to shore up those aluminum beds.