Could Beer Power Your Electric Car?

It sounds like a car guy’s fantasy, using beer to power a car.

And it still is fantasy, unfortunately.

However, a couple of researchers at the University of Colorado Boulder have filed for a patent on a method to use the byproduct of the brewing process to create anodes for lithium-ion batteries, the power source for most electric cars.

Currently, no pun intended, the very pure graphite that is used to make lithium-ion batteries is mined, primarily in China, and then doped with other elements like cobalt and magnesium as it is processed into anodes. Engineers Justin Whiteley and Tyler Huggins say their method is more environmentally friendly than mining, more sustainable, and — of greatest importance in commercializing the process — cheaper than extracting it from the earth.

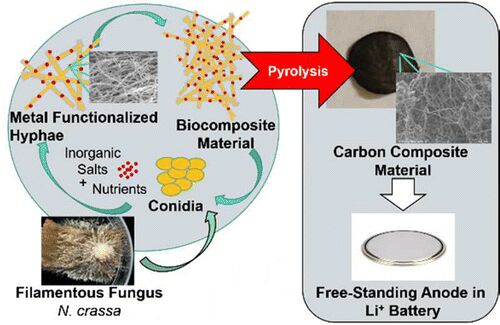

Besides cleaning up the battery building process, the method also promises to make brewing beer more environmentally friendly. It takes about seven barrels of water to make one barrel of beer. That six gallons of wastewater contains sugars and organic materials that have to be rigorously filtered before it can be returned to municipal water systems. Working with Boulder’s Avery Brewing, Huggins and Whiteley used the wastewater to feed the mycelium of a fungus called Neurospora crassa, cultivated on growing media that was rich in cobalt and magnesium. Mycelium is the filamentous vegetative stage of life for fungi between spores and fruit. The fungus effectively filters the water as it consumes the contaminants.

Once grown, the fungus is dried and then baked (actually, pyrolyzed) at 800°C, and the result is a co-doped electrode material that is ready to be used in batteries.

Whiteley told Boulder’s Fox 31, “Out pops this carbon, and that goes right into the battery, that will be one-half of your lithium-ion battery.”

If the abstract below piques your interest, you can read the full study in Applied Materials & Interfaces, a journal of the American Chemical Society.

Biomass can serve as a sustainable template for the synthesis of carbon materials but is limited by the intrinsic properties of the precursor organism. In this study we demonstrate that the properties of a fungal biotemplate can be tuned during cultivation, establishing a new electrode manufacturing process and ultimately improving the electrochemical performance of the biomass-derived electrode. More specifically, the carbon/nitrogen ratio of Neurospora crassa mycelia mats was shifted by 5-fold while generating cobalt nanoparticles into the hyphal structure originating from macroconidia spores. This shift was achieved through nitrate limitation and equal molar concentrations of Mg2+ and Co2+ in the growth media. The resulting mycelia mat was converted via a high-temperature pyrolysis process (800 °C) to produce a freestanding cobalt and nitrogen codoped electrode material with no postmodification. Ultimately, nitrogen doping resulted in one of the highest recorded specific reversible capacity for a freestanding biomass-derived lithium-ion anode (400 mAh g–1 at C/10). We observed an additional improvement in capacity to 425 mAh g–1 with the incorporation of 3 wt % Co. Our results show how shaping the chemical characteristics of an electrode during the growth of the biotemplate allows for sustainable carbon-based material manufacturing from a living (self-assembled) material.

[Image source: University of Colorado Boulder]

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Kjhkjlhkjhkljh kljhjkhjklhkjh A prelude is a bad idea. There is already Acura with all the weird sport trims. This will not make back it's R&D money.

- Analoggrotto I don't see a red car here, how blazing stupid are you people?

- Redapple2 Love the wheels

- Redapple2 Good luck to them. They used to make great cars. 510. 240Z, Sentra SE-R. Maxima. Frontier.

- Joe65688619 Under Ghosn they went through the same short-term bottom-line thinking that GM did in the 80s/90s, and they have not recovered say, to their heyday in the 50s and 60s in terms of market share and innovation. Poor design decisions (a CVT in their front-wheel drive "4-Door Sports Car", model overlap in a poorly performing segment (they never needed the Altima AND the Maxima...what they needed was one vehicle with different drivetrain, including hybrid, to compete with the Accord/Camry, and decontenting their vehicles: My 2012 QX56 (I know, not a Nissan, but the same holds for the Armada) had power rear windows in the cargo area that could vent, a glass hatch on the back door that could be opened separate from the whole liftgate (in such a tall vehicle, kinda essential if you have it in a garage and want to load the trunk without having to open the garage door to make room for the lift gate), a nice driver's side folding armrest, and a few other quality-of-life details absent from my 2018 QX80. In a competitive market this attention to detai is can be the differentiator that sell cars. Now they are caught in the middle of the market, competing more with Hyundai and Kia and selling discounted vehicles near the same price points, but losing money on them. They invested also invested a lot in niche platforms. The Leaf was one of the first full EVs, but never really evolved. They misjudged the market - luxury EVs are selling, small budget models not so much. Variable compression engines offering little in terms of real-world power or tech, let a lot of complexity that is leading to higher failure rates. Aside from the Z and GT-R (low volume models), not much forced induction (whether your a fan or not, look at what Honda did with the CR-V and Acura RDX - same chassis, slap a turbo on it, make it nicer inside, and now you can sell it as a semi-premium brand with higher markup). That said, I do believe they retain the technical and engineering capability to do far better. About time management realized they need to make smarter investments and understand their markets better.

Comments

Join the conversation

Betteridge's law of headlines confirmed.

Thinking outside the box.