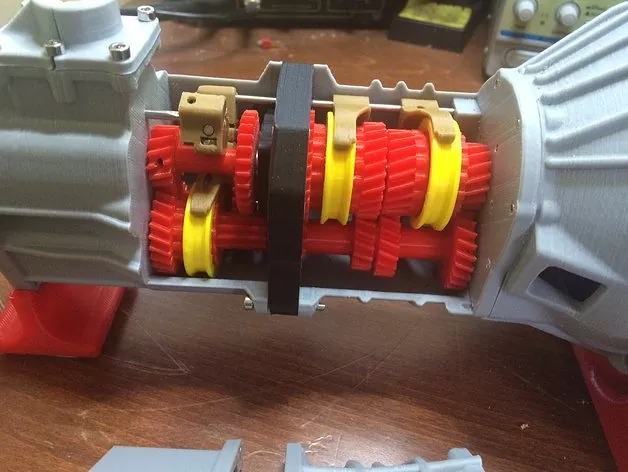

Make Your Own Toyota Transmission At Home (Kind Of)

“The transmission works exactly like most manual transmissions found in any car or truck,” explained Harrell. “However, I can barely explain how it works. It’s fairly hard to grasp unless you assemble one or see an animation of one opened up.”

Last year, I wrote Concours d’Angst as a vision of what small-scale manufacturing might bring to the automotive enthusiast landscape. While I was busy imagining the future, however, someone else was busy making it.

It’s a 3-D printed Toyota transmission made of plastic, for use with a similarly small-scale Toyota 22R engine. You can see it work here:

Obviously, this is neither full-sized nor ready to install in any engine of any type. What makes it important is that it was reverse-engineered by someone who was in no way involved with Toyota, or even with transmissions. As 3-D printing transcends technical limitations and becomes a lingua franca for small-scale fabrication of all types, it will become possible for hobbyists to immediately produce full-sized steel transmissions and other complex parts themselves. It will also become commonplace for those designs to be shared. Imagine a world where you could obtain almost any out-of-stock part for any car through this process, and you’ll see the possibilities.

There will be problems of course — how will you be able to be absolutely sure that the transmission in that hundred-year-old ’77 Celica you just paid two million New Dollars for was machined from tool-grade steel? — but those problems will also be solved as time goes on.

Now, if you’ll excuse me, I’m going to wait for somebody to build me a new four-speed 1990 Fox.

More by Jack Baruth

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- TheEndlessEnigma These cars were bought and hooned. This is a bomb waiting to go off in an owner's driveway.

- Kwik_Shift_Pro4X Thankfully I don't have to deal with GDI issues in my Frontier. These cleaners should do well for me if I win.

- Theflyersfan Serious answer time...Honda used to stand for excellence in auto engineering. Their first main claim to fame was the CVCC (we don't need a catalytic converter!) engine and it sent from there. Their suspensions, their VTEC engines, slick manual transmissions, even a stowing minivan seat, all theirs. But I think they've been coasting a bit lately. Yes, the Civic Type-R has a powerful small engine, but the Honda of old would have found a way to get more revs out of it and make it feel like an i-VTEC engine of old instead of any old turbo engine that can be found in a multitude of performance small cars. Their 1.5L turbo-4...well...have they ever figured out the oil dilution problems? Very un-Honda-like. Paint issues that still linger. Cheaper feeling interior trim. All things that fly in the face of what Honda once was. The only thing that they seem to have kept have been the sales staff that treat you with utter contempt for daring to walk into their inner sanctum and wanting a deal on something that isn't a bare-bones CR-V. So Honda, beat the rest of your Japanese and Korean rivals, and plug-in hybridize everything. If you want a relatively (in an engineering way) easy way to get ahead of the curve, raise the CAFE score, and have a major point to advertise, and be able to sell to those who can't plug in easily, sell them on something that will get, for example, 35% better mileage, plug in when you get a chance, and drives like a Honda. Bring back some of the engineering skills that Honda once stood for. And then start introducing a portfolio of EVs once people are more comfortable with the idea of plugging in. People seeing that they can easily use an EV for their daily errands with the gas engine never starting will eventually sell them on a future EV because that range anxiety will be lessened. The all EV leap is still a bridge too far, especially as recent sales numbers have shown. Baby steps. That's how you win people over.

- Theflyersfan If this saves (or delays) an expensive carbon brushing off of the valves down the road, I'll take a case. I understand that can be a very expensive bit of scheduled maintenance.

- Zipper69 A Mini should have 2 doors and 4 cylinders and tires the size of dinner plates.All else is puffery.

Comments

Join the conversation

The main thing with 3-D printing is that it changes the economics for producing one-off or small runs of things. It's not going to cause factories to disappear and people to have cars automatically assembled in their garages, anymore than CNC milling did. It will, though, revolutionize the aftermarket in both underhood parts and interior/exterior bling. I want one of those model transmissions...

3D Printing has changed the face of car manufacturing.