Born From Kits: Volkswagen Invents The Incredible Money Machine

We have been writing about it for years, now, Bloomberg wakes up to it:

“Volkswagen AG will kick off its biggest technology overhaul in almost two decades.”

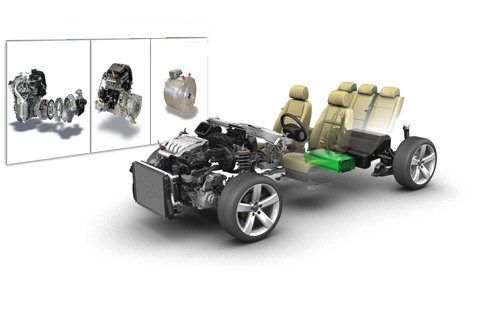

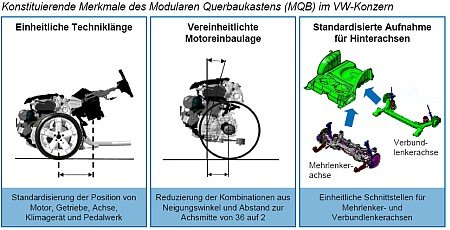

Bloomberg still has a hard time of coming to grips with the technological revolution. It’s not just that “more than 40 models will use a set of standardized components such as axles, steering columns and chassis,” as Bloomberg puts it. This is not a parts bin exercise. Through the Volkswagen empire, cars don’t just share the same steering columns. They are designed using standardized building blocks of a common kit architecture.

The kits have Teutonic names like “Modularer Querbaukasten” (MQB) and “Modularer Längsbaukasten” (MLB). Porsche is developing a “MMB” (Modularer Mittelbaukasten) for Mittelmotor (mid-engined) cars.

Volkswagen engineers are already working on the next generation of Baukastens, which could be the Mutter of all Baukasten.

According to Bloomberg, the exercise may lower costs by 5 billion Euros ($6.5 billion) a year, and cut assembly times by 30 percent.

Not quite understanding the kit architecture, Bloomberg raises the specter that one wrong bolt could now bring the whole company down. They cite Christoph Stuermer, a Frankfurt-based analyst with IHS Automotive, which is not known for its precise predictions:

“If something goes wrong, then one may get hit by an epidemic plague. The more connected the structures, the higher the threat of contagion.”

Volkswagen already has quite cleverly leveraged platforms across models, brands and segments. There is very little similarity between an Audi TT and a Volkswagen Beetle, despite them (and a panoply of others) sharing the same underpinnings. The kit architecture takes this principle to a new dimension. Properly executed, it can make for a very profitable car company. Juergen Pieper, an analyst with Bankhaus Metzler inFrankfurt, estimates that the technology will save 5 billion Euros by 2016, and says:

“The parts-sharing program is a very big lever to improve profitability that other companies don’t make use of because of the complexity. Without this cost-cutting program, margins wouldn’t likely rise from this year’s peak.”

Volkswagen reported an operating margin of 7.7 percent through the first nine months of 2011 and has a goal of lifting that to more than 8 percent by 2018. Without the new vehicle architecture, margins could average about 6 percent, said Pieper.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Peter Buying an EV from Toyota is like buying a Bible from Donald Trump. Don’t be surprised if some very important parts are left out.

- Sheila I have a 2016 Kia Sorento that just threw a rod out of the engine case. Filed a claim for new engine and was denied…..due to a loop hole that was included in the Class Action Engine Settlement so Hyundai and Kia would be able to deny a large percentage of cars with prematurely failed engines. It’s called the KSDS Improvement Campaign. Ever hear of such a thing? It’s not even a Recall, although they know these engines are very dangerous. As unknowing consumers load themselves and kids in them everyday. Are their any new Class Action Lawsuits that anyone knows of?

- Alan Well, it will take 30 years to fix Nissan up after the Renault Alliance reduced Nissan to a paltry mess.I think Nissan will eventually improve.

- Alan This will be overpriced for what it offers.I think the "Western" auto manufacturers rip off the consumer with the Thai and Chinese made vehicles.A Chinese made Model 3 in Australia is over $70k AUD(for 1995 $45k USD) which is far more expensive than a similar Chinesium EV of equal or better quality and loaded with goodies.Chinese pickups are $20k to $30k cheaper than Thai built pickups from Ford and the Japanese brands. Who's ripping who off?

- Alan Years ago Jack Baruth held a "competition" for a piece from the B&B on the oddest pickup story (or something like that). I think 5 people were awarded the prizes.I never received mine, something about being in Australia. If TTAC is global how do you offer prizes to those overseas or are we omitted on the sly from competing?In the end I lost significant respect for Baruth.

Comments

Join the conversation

gslippy is right, this to me sounds like a new spin on an old idea. Ok sure the Audi doesn't share the same parts as the VW.. ya know what? I don't care, you line the cars up side by side, along with the Skoda (not available in the USA) in their respective size and the amount of differentiation is negligible. On top of that, package in the long wheelbase models that you get here in China and frankly it becomes nearly impossible to tell an A4L from an A6 and an A6L from an A8 While the company is certainly containing it's costs through all this shared architecture, they have become so ubiquitous here in Shanghai that they are even more bland looking than Japanese cars. If you guys think Toyota is the definition of bland looking cars, come here. VW/Audi I truly feel is the most bland looking car company for sale today. There is so little differentiation between car sizes and sub-brands that I frequently wonder why they are selling so many different brands. It's so bad here I actually get excited when I see a Lexus just for something different.

Now, all VW (or someone else) needs to do, is making the specs for each of these components/sub assemblies public, along with a compliance testing procedure; and the automotive industry would finally at least be attempting to play catchup with consumer electronics :)