Japanese Parts Paralysis: Lack Of Chips For Cars Can Cost $76 Billion

When we worked on the Phaeton launch in 2001, we said it had “more computers than a small company.” It had 56. Today’s cars have anywhere between 30 and 100 computers on board. They are small microcontrollers that typically chat with each other via a CAN bus. You don’t take just any microcontroller for the job. They need to hold up to the harsh environment inside of a car. Their makers need to hold up to the harsh environment presented by the purchasing departments of automakers that squeeze them for every penny. As a result of both, there are only a few players in this field. This is the story of one of them.

The largest manufacturer of automotive microcontrollers is Renesas, followed by Infineon, STM, Freescale and Bosch.

Renesas controls about 41 percent of the global market for automotive microcontrollers, says Automotive News [sub]. EE Times gives them only 11 percent. But all agree, Renesas is the largest in the automotive field. The world’s largest automaker, Toyota, is said to be the largest customer of Renesas.

Renesas, which had merged with NEC Electronics, has 90 percent of its global capacity in Japan.

If you want to relive how the chip giant was battling with the damage caused by the earthquake and tsunami, how they coped and cope with the power outages, then you find the blow-by-blow here.

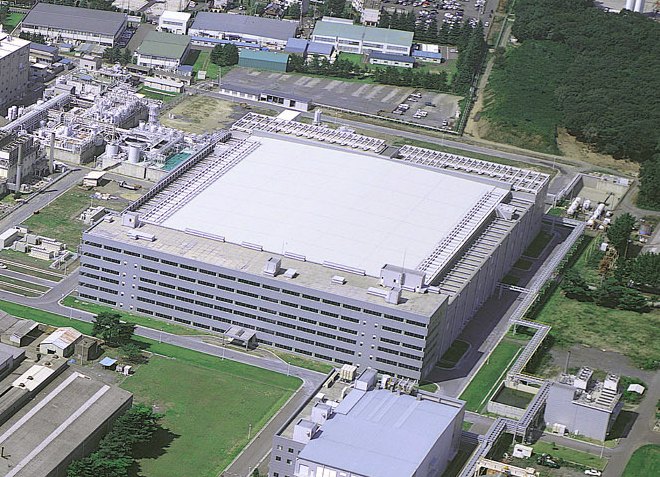

From the first notice on March 14, the Monday after the quake (7 out of 22 factories down, 8 impacted by power outage) to the last one from just two days ago. In this notice, you see that Renesas is slowly getting back to normal, except for one fab: The Naka fab, in Hitachinaka-shi, Ibaraki Prefecture . This plant is listed as “Temporarily shutting production.“ The plant is down for the duration, tentative target date for re-opening: July 2011. Or thereabouts.

The trouble is, fate wanted it that “Renesas’ Naka plant in northeastern Japan accounts for about 25 percent of its global automotive microcontroller capacity,” says Automotive News. If the world’s largest supplier of automotive microcontrollers loses a quarter of its capacity, someone will get hurt.

According to AN, Renesas will most likely shift production from Naka to other Renesas fabs in Japan or Singapore. And now digest this quote from the report:

“But that transfer will account for less than half of Naka’s output, and it could be another two months before production starts up at those sites.

The manufacturing process for microcontrollers, or MCUs, can take up to two months, meaning that it could be another four months before those new sites are sending finished products to customers.”

Renesas thinks it can fill “approximately 70 percent of the customer orders currently in place with the Naka factory that are requested to be delivered by the end of May, from the finished goods already in stock and work-in-process goods in the assembly lines.”

After that, Renesas President Yasushi Akao is hoping for the “kind understanding and support” from his customers.

This little spotlight shows that things are not as clear cut as they appear. Nothing happens for a while. The first impact from Naka will be felt in June, when 30 percent of the orders remain unfilled. The second impact will hit when the deliveries are used up, and new chips won’t be flowing until September. These are no chips you can order from the Digikey catalog. These are specialized chips for special applications. Sourcing them from another manufacturer would take even longer.

Last night’s 7.1 magnitude aftershock left four Renesas fabs in northern Japan without power, says Reuters. It is unclear when production will be restarted.

And this is just one out of many suppliers.

Update: The Japanese government just chimed in (via The Nikkei [sub]: If production of the “key automobile component”, (namely the microcontrollers) “does not resume for the six-week period through the end of April, it could result in a loss of around 6.5 trillion yen for auto manufacturing worldwide, according to the government estimate.” According to my calculator, that is $ 76.4 billion. The reader of the above knows by now: At least 25 percent of the supply will be missing for a while.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jalop1991 In a manner similar to PHEV being the correct answer, I declare RPVs to be the correct answer here.We're doing it with certain aircraft; why not with cars on the ground, using hardware and tools like Telsa's "FSD" or GM's "SuperCruise" as the base?Take the local Uber driver out of the car, and put him in a professional centralized environment from where he drives me around. The system and the individual car can have awareness as well as gates, but he's responsible for the driving.Put the tech into my car, and let me buy it as needed. I need someone else to drive me home; hit the button and voila, I've hired a driver for the moment. I don't want to drive 11 hours to my vacation spot; hire the remote pilot for that. When I get there, I have my car and he's still at his normal location, piloting cars for other people.The system would allow for driver rest period, like what's required for truckers, so I might end up with multiple people driving me to the coast. I don't care. And they don't have to be physically with me, therefore they can be way cheaper.Charge taxi-type per-mile rates. For long drives, offer per-trip rates. Offer subscriptions, including miles/hours. Whatever.(And for grins, dress the remote pilots all as Johnnie.)Start this out with big rigs. Take the trucker away from the long haul driving, and let him be there for emergencies and the short haul parts of the trip.And in a manner similar to PHEVs being discredited, I fully expect to be razzed for this brilliant idea (not unlike how Alan Kay wasn't recognized until many many years later for his Dynabook vision).

- B-BodyBuick84 Not afraid of AV's as I highly doubt they will ever be %100 viable for our roads. Stop-and-go downtown city or rush hour highway traffic? I can see that, but otherwise there's simply too many variables. Bad weather conditions, faded road lines or markings, reflective surfaces with glare, etc. There's also the issue of cultural norms. About a decade ago there was actually an online test called 'The Morality Machine' one could do online where you were in control of an AV and choose what action to take when a crash was inevitable. I think something like 2.5 million people across the world participated? For example, do you hit and most likely kill the elderly couple strolling across the crosswalk or crash the vehicle into a cement barrier and almost certainly cause the death of the vehicle occupants? What if it's a parent and child? In N. America 98% of people choose to hit the elderly couple and save themselves while in Asia, the exact opposite happened where 98% choose to hit the parent and child. Why? Cultural differences. Asia puts a lot of emphasis on respecting their elderly while N. America has a culture of 'save/ protect the children'. Are these AV's going to respect that culture? Is a VW Jetta or Buick Envision AV going to have different programming depending on whether it's sold in Canada or Taiwan? how's that going to effect legislation and legal battles when a crash inevitibly does happen? These are the true barriers to mass AV adoption, and in the 10 years since that test came out, there has been zero answers or progress on this matter. So no, I'm not afraid of AV's simply because with the exception of a few specific situations, most avenues are going to prove to be a dead-end for automakers.

- Mike Bradley Autonomous cars were developed in Silicon Valley. For new products there, the standard business plan is to put a barely-functioning product on the market right away and wait for the early-adopter customers to find the flaws. That's exactly what's happened. Detroit's plan is pretty much the opposite, but Detroit isn't developing this product. That's why dealers, for instance, haven't been trained in the cars.

- Dartman https://apnews.com/article/artificial-intelligence-fighter-jets-air-force-6a1100c96a73ca9b7f41cbd6a2753fdaAutonomous/Ai is here now. The question is implementation and acceptance.

- FreedMike If Dodge were smart - and I don't think they are - they'd spend their money refreshing and reworking the Durango (which I think is entering model year 3,221), versus going down the same "stuff 'em full of motor and give 'em cool new paint options" path. That's the approach they used with the Charger and Challenger, and both those models are dead. The Durango is still a strong product in a strong market; why not keep it fresher?

Comments

Join the conversation

Interesting stuff, Bertel. This really helps to illustrate how complex such things as automobile production have become, and how dependent current production practices are on everything working together perfectly all the time. Market pressures have caused the production process to become so strongly oriented towards maximizing efficiency (in the reduction of costs and so on) that things seem more and more to be run on the almost irrational hope that nothing will ever go wrong. As a result, processes become increasingly specialized and inflexible. It's great when it works, but when something goes wrong, it's crisis management time.

While I don't doubt that "These are no chips you can order from the Digikey catalog. These are specialized chips for special applications.", it shouldn't be that hard to move production to a different foundry. The chips themselves may be somewhat specialized, but they are most likely made with standard processes and design rules. I would think it would be easier to second source chips than the big heavy greasy parts of a car. If the power in Japan is going to be spotty for a while, I can see production of these components moving to fab shops in places like Singapore or Taiwan. There might be some short term supply issues, but I don't see this one dragging on for months...