Japanese Parts Paralysis: Lack Of Chips For Cars Can Cost $76 Billion

When we worked on the Phaeton launch in 2001, we said it had “more computers than a small company.” It had 56. Today’s cars have anywhere between 30 and 100 computers on board. They are small microcontrollers that typically chat with each other via a CAN bus. You don’t take just any microcontroller for the job. They need to hold up to the harsh environment inside of a car. Their makers need to hold up to the harsh environment presented by the purchasing departments of automakers that squeeze them for every penny. As a result of both, there are only a few players in this field. This is the story of one of them.

The largest manufacturer of automotive microcontrollers is Renesas, followed by Infineon, STM, Freescale and Bosch.

Renesas controls about 41 percent of the global market for automotive microcontrollers, says Automotive News [sub]. EE Times gives them only 11 percent. But all agree, Renesas is the largest in the automotive field. The world’s largest automaker, Toyota, is said to be the largest customer of Renesas.

Renesas, which had merged with NEC Electronics, has 90 percent of its global capacity in Japan.

If you want to relive how the chip giant was battling with the damage caused by the earthquake and tsunami, how they coped and cope with the power outages, then you find the blow-by-blow here.

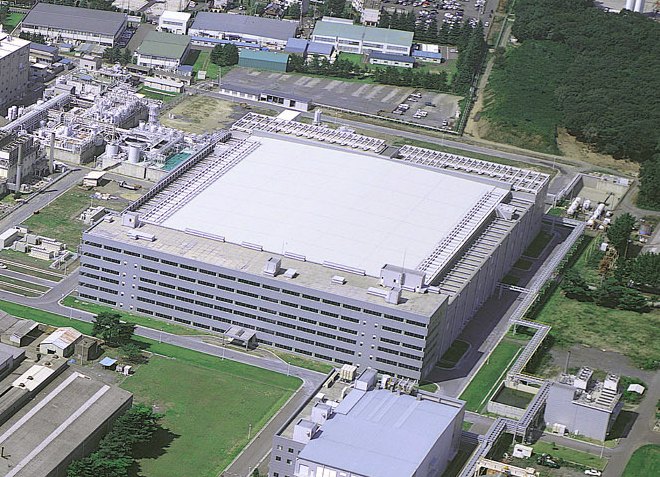

From the first notice on March 14, the Monday after the quake (7 out of 22 factories down, 8 impacted by power outage) to the last one from just two days ago. In this notice, you see that Renesas is slowly getting back to normal, except for one fab: The Naka fab, in Hitachinaka-shi, Ibaraki Prefecture . This plant is listed as “Temporarily shutting production.“ The plant is down for the duration, tentative target date for re-opening: July 2011. Or thereabouts.

The trouble is, fate wanted it that “Renesas’ Naka plant in northeastern Japan accounts for about 25 percent of its global automotive microcontroller capacity,” says Automotive News. If the world’s largest supplier of automotive microcontrollers loses a quarter of its capacity, someone will get hurt.

According to AN, Renesas will most likely shift production from Naka to other Renesas fabs in Japan or Singapore. And now digest this quote from the report:

“But that transfer will account for less than half of Naka’s output, and it could be another two months before production starts up at those sites.

The manufacturing process for microcontrollers, or MCUs, can take up to two months, meaning that it could be another four months before those new sites are sending finished products to customers.”

Renesas thinks it can fill “approximately 70 percent of the customer orders currently in place with the Naka factory that are requested to be delivered by the end of May, from the finished goods already in stock and work-in-process goods in the assembly lines.”

After that, Renesas President Yasushi Akao is hoping for the “kind understanding and support” from his customers.

This little spotlight shows that things are not as clear cut as they appear. Nothing happens for a while. The first impact from Naka will be felt in June, when 30 percent of the orders remain unfilled. The second impact will hit when the deliveries are used up, and new chips won’t be flowing until September. These are no chips you can order from the Digikey catalog. These are specialized chips for special applications. Sourcing them from another manufacturer would take even longer.

Last night’s 7.1 magnitude aftershock left four Renesas fabs in northern Japan without power, says Reuters. It is unclear when production will be restarted.

And this is just one out of many suppliers.

Update: The Japanese government just chimed in (via The Nikkei [sub]: If production of the “key automobile component”, (namely the microcontrollers) “does not resume for the six-week period through the end of April, it could result in a loss of around 6.5 trillion yen for auto manufacturing worldwide, according to the government estimate.” According to my calculator, that is $ 76.4 billion. The reader of the above knows by now: At least 25 percent of the supply will be missing for a while.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Redapple2 I gave up on Honda. My 09 Accord Vs my 03. The 09s- V 6 had a slight shudder when deactivating cylinders. And the 09 did not have the 03 's electro luminescent gages. And the 09 had the most uncomfortable seats. My brother bought his 3rd and last Honda CRV. Brutal seats after 25 minutes. NOW, We are forever Toyota, Lexus, Subaru people now despite HAVING ACCESS TO gm EMPLOYEE DISCOUNT. Despite having access to the gm employee discount. Man, that is a massive statement. Wow that s bad - Under no circumstances will I have that govna crap.

- Redapple2 Front tag obscured. Rear tag - clear and sharp. Huh?

- Redapple2 I can state what NOT to buy. HK. High theft. Insurance. Unrefined NVH. Rapidly degrading interiors. HK? No way !

- Luke42 Serious answer:Now that I DD an EV, buying an EV to replace my wife’s Honda Civic is in the queue. My wife likes her Honda, she likes Apple CarPlay, and she can’t stand Elon Musk - so Tesla starts the competition with two demerit-points and Honda starts the competition with one merit-point.The Honda Prologue looked like a great candidate until Honda announced that the partnership with GM was a one-off thing and that their future EVs would be designed in-house.Now I’m more inclined toward the Blazer EV, the vehicle on which the Prologue is based. The Blazer EV and the Ultium platform won’t be orphaned by GM any time soon. But then I have to convince my wife she would like it better than her Honda Civic, and that’s a heavy lift because she doesn’t have any reason to be dissatisfied with her current car (I take care of all of the ICE-hassles for her).Since my wife’s Honda Civic is holding up well, since she likes the car, and since I take care of most of the drawbacks of drawbacks of ICE ownership for her, there’s no urgency to replace this vehicle.Honestly, if a paid-off Honda Civic is my wife’s automotive hill to die on, that’s a pretty good place to be - even though I personally have to continue dealing the hassles and expenses of ICE ownership on her behalf.My plan is simply to wait-and-see what Honda does next. Maybe they’ll introduce the perfect EV for her one day, and I’ll just go buy it.

- 2ACL I have a soft spot for high-performance, shark-nosed Lancers (I considered the less-potent Ralliart during the period in which I eventually selected my first TL SH-AWD), but it's can be challenging to find a specimen that doesn't exhibit signs of abuse, and while most of the components are sufficiently universal in their function to service without manufacturer support, the SST isn't one of them. The shops that specialize in it are familiar with the failure as described by the seller and thus might be able to fix this one at a substantial savings to replacement. There's only a handful of them in the nation, however. A salvaged unit is another option, but the usual risks are magnified by similar logistical challenges to trying to save the original.I hope this is a case of the seller overvaluing the Evo market rather than still owing or having put the mods on credit. Because the best offer won't be anywhere near the current listing.

Comments

Join the conversation

Interesting stuff, Bertel. This really helps to illustrate how complex such things as automobile production have become, and how dependent current production practices are on everything working together perfectly all the time. Market pressures have caused the production process to become so strongly oriented towards maximizing efficiency (in the reduction of costs and so on) that things seem more and more to be run on the almost irrational hope that nothing will ever go wrong. As a result, processes become increasingly specialized and inflexible. It's great when it works, but when something goes wrong, it's crisis management time.

While I don't doubt that "These are no chips you can order from the Digikey catalog. These are specialized chips for special applications.", it shouldn't be that hard to move production to a different foundry. The chips themselves may be somewhat specialized, but they are most likely made with standard processes and design rules. I would think it would be easier to second source chips than the big heavy greasy parts of a car. If the power in Japan is going to be spotty for a while, I can see production of these components moving to fab shops in places like Singapore or Taiwan. There might be some short term supply issues, but I don't see this one dragging on for months...