DeGiorgio: 'I Did What I Was Supposed To Do'

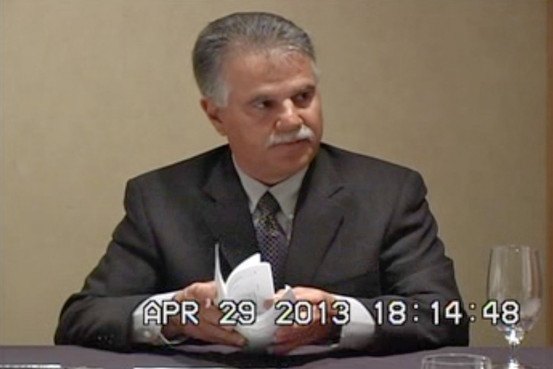

Since being dismissed from General Motors in June of 2014, the engineer cited by the Valukas report as the main culprit behind what would lead to the February 2014 ignition switch recall crisis had been in seclusion. Until now.

The New York Times recently interviewed Raymond DeGiorgio outside his suburban Detroit home. When asked about the switch and the deaths and injuries linked to it, DeGiorgio proclaimed that he was just doing his job, doing what he was supposed to do, and that he did the best that he could.

An executive working at one of GM’s suppliers said the engineer was part of “the frozen middle” inside the automaker’s technical center in Warren, Mich., a culture which kept to itself, focused on the jobs before it, and prevented others from entering.

DeGiorgio’s tribulations began in 2001, when he was tasked with choosing a switch from two proposed. The one chosen required less force to turn the key, to the detriment of the switch’s overall quality. He would spend the next few years trying to have the switch improved, ending with a rejected request in September 2005 for a new switch meant for an upcoming GM product. A few months later in May 2006, DeGiorgio would make the fateful decision to have supplier Delphi replace the switch with the version he passed over, failing to change the part number associated in so doing.

Before corporate investigators in 2009 and 2012, and in a 2013 deposition, the engineer claimed he did not authorize a change in the ignition switch, though he did admit to seeing the difference between the two in the aforementioned deposition. The downward spiral for both DeGiorgio and GM soon followed.

Amid multiple legal threats, including criminal and perjury charges, he still holds the line that he did nothing wrong, that he and his name were “trashed” and “crucified” before the public. He added that the some of the various pieces written of him and his time at GM were “fiction,” but when asked for clarification, DeGiorgio ended the interview with the following:

I could write a book just about the switch. Maybe someday I will.

Seattle-based writer, blogger, and photographer for many a publication. Born in Louisville. Raised in Kansas. Where I lay my head is home.

More by Cameron Aubernon

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Lou_BC Well, I'd be impressed if this was in a ZR2. LOL

- Lou_BC This is my shocked face 😲 Hope formatting doesn't fook this up LOL

- Lou_BC Junior? Would that be a Beta Romeo?

- Lou_BC Gotta fix that formatting problem. What a pile of bullsh!t. Are longer posts costing TTAC money? FOOK

- Lou_BC 1.Honda: 6,334,825 vehicles potentially affected2.Ford: 6,152,6143.Kia America: 3,110,4474.Chrysler: 2,732,3985.General Motors: 2,021,0336.Nissan North America: 1,804,4437.Mercedes-Benz USA: 478,1738.Volkswagen Group of America: 453,7639.BMW of North America: 340,24910.Daimler Trucks North America: 261,959

Comments

Join the conversation

In any large organization, when the sh*t hits the fan, there's a search for the guilty party, AKA scapegoat. In an organization as big as GM, with sh*t hitting thousands of fans, how can you claim just one monkey threw it?

I work in automotive R&D. I'm not an engineer, I just work with them. DeGorgio could be one of them. Upon a mistake, some of my colleagues would also respond with "I did what I was supposed to!", which might as well be "I did nothing wrong!". And they really mean it. It must be some mental condition like Asperger or something. Infantile ignorant incompetence is bliss for some. Unfortunately there are too many people like this at work, not getting purged. And sometimes, they get promoted into a position of great responsibility. Ever heard of the Peter principle?