Yamanouchi: Mazda's Mexico Factory Key To Global Strategy

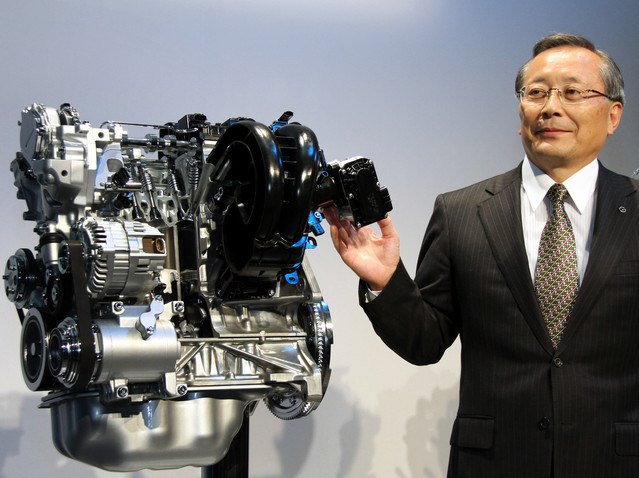

Mazda Chairman Takashi Yamanouchi opened his company’s sole North American factory in Salamanca, Mexico, proclaiming the new factory the key to a global strategy “upon which the very future of [the] company hinges.”

Automotive News reports the strategy with the factory — Mazda’s Structural Reform Plan — follows a three-pronged approach: a hedge against currency exchange disruptions, provide Mazda with a low-cost manufacturing base, and give the automaker access to new markets. The factory’s location allows the automaker to gain more profit for the Mazda3s destined for the United States, than those exported from Japan, while also providing an export base to Europe and access to new markets in Latin America. In turn, Mazda’s new access through Mexico’s free trade pacts provides to markers worth a combined 35 million to 40 million vehicle sales annually.

Though the yen is weakening against the dollar at the moment, Yamanouchi said the factory will act as a hedge against unpredictable currency fluctuations that could bring down profits for his company at any time:

When the yen becomes stronger, we have the Mexican plant, therefore we will never again go into the lost position. But when the yen gets weaker, we will further cost reduce the Mexican plants so it will contribute to our total profitability. Our philosophy is that we will strike the balance of business so that we won’t go into the very difficult times of the past that we have experienced. Never.

The factory is expected to employ 4,600 workers once at full capacity of 230,000 units/annually. Currently, 3,000 employees assemble Mazda3s for the North American market, which will be joined by the Mazda2 and a Mazda2-based vehicle for Toyota. An engine machining plant will also set up shop in the factory by October 2014.

Seattle-based writer, blogger, and photographer for many a publication. Born in Louisville. Raised in Kansas. Where I lay my head is home.

More by Cameron Aubernon

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Brandon I would vote for my 23 Escape ST-Line with the 2.0L turbo and a normal 8 speed transmission instead of CVT. 250 HP, I average 28 MPG and get much higher on trips and get a nice 13" sync4 touchscreen. It leaves these 2 in my dust literally

- JLGOLDEN When this and Hornet were revealed, I expected BOTH to quickly become best-sellers for their brands. They look great, and seem like interesting and fun alternatives in a crowded market. Alas, ambitious pricing is a bridge too far...

- Zerofoo Modifications are funny things. I like the smoked side marker look - however having seen too many cars with butchered wire harnesses, I don't buy cars with ANY modifications. Pro-tip - put the car back to stock before you try and sell it.

- JLGOLDEN I disagree with the author's comment on the current Murano's "annoying CVT". Murano's CVT does not fake shifts like some CVTs attempt, therefore does not cause shift shock or driveline harshness while fumbling between set ratios. Murano's CVT feels genuinely smooth and lets the (great-sounding V6) engine sing and zing along pleasantly.

- JLGOLDEN Our family bought a 2012 Murano AWD new, and enjoyed it for 280K before we sold it last month. CVT began slipping at 230K but it was worth fixing a clean, well-cared for car. As soon as we sold the 2012, I grabbed a new 2024 Murano before the body style and powertrain changes for 2025, and (as rumored) goes to 4-cyl turbo. Sure, the current Murano feels old-school, with interior switchgear and finishes akin to a 2010 Infiniti. That's not a bad thing! Feels solid, V6 sounds awesome, and the whole platform has been around long enough that future parts & service wont be an issue.

Comments

Join the conversation

What Mazda needs is a strategy to surpass 2% market share in the US market. They haven't sold more than 295k cars/year since 2002; 2013 was 283k. The 3 alone is nearly 40% of Mazda's sales volume, and the 6 is another 15%. I don't know how they can afford to produce all those other models.

How long have Toyota, Nissan and Honda had plants where their cars are sold? Didn't Henry Ford build plants in England, Germany and Russia, where his model T sales were? What took Mazda so long to figure it out?