Why Toyota Must Replace Flawed CTS Gas Pedal With Superior Denso Pedal

Update: a portal to all of TTAC’s articles on the subject of Toyota gas pedals is here:

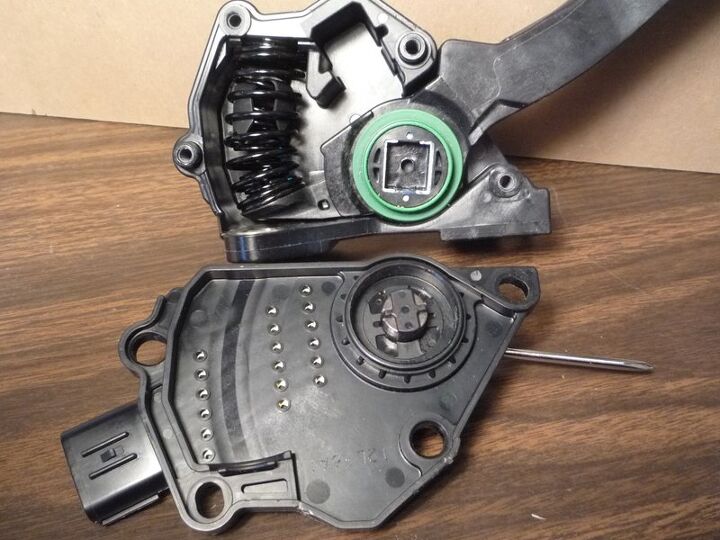

Toyota uses two different electronic gas pedal designs in its cars. The version built by CTS (lower) is the subject of a massive recall, and the 2.3 million units in affected Toyota cars are to be “fixed” by the insertion of a steel shim. This CTS design is also being modified for new Toyota production, currently suspended. To our knowledge, Toyotas built with the other design (by Denso, upper) are not subject to any recalls or NHTSA investigations,. We have spent the last two days tearing down both units, and familiarized ourselves with their designs, reviewed Toyota’s “shim fix”, and replicated the fix ourselves. Toyota’s planned fix will undoubtedly reduce the likelihood of sticky pedals in the short term, but after examining both units, we are convinced that the CTS unit is intrinsically a flawed design, and poses safety risks in the long term, even with the fix. The only right action for Toyota is to acknowledge the long history of problems with the CTS-type unit, and replace them all with the superior Denso or another pedal unit that lacks the intrinsic flaws of the CTS design.

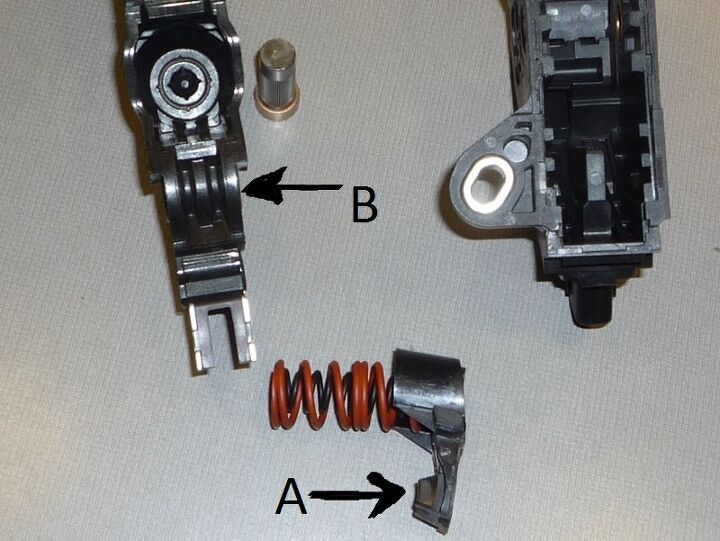

The key component in question is the friction arm of the CTS. It is both essential and desirable to have a certain defined degree of friction in these electronic gas pedal assemblies. The amount of friction is designed to be some degree less than the return spring, so that when the pedal is released, it returns to the closed position. But the friction (hysteresis) makes it easier to maintain a steady throttle setting, and relieves strain from pushing against the spring continuously. It simulates the intrinsic friction that is present in the traditional throttle cable as it passes through the cable housing.

The two units generate the desired degree of friction in very different ways. In the Denso unit (above), the return spring (steel coil) is squeezed on both sides of its housing. It rubs against the plastic housing as it compresses, which generates the desired amount of friction. Both sides of the full length of the Denso coil are in continuous contact with the rubbed are, spreading out the contact area size. And the metal to plastic interface seems to be relatively unproblematic.

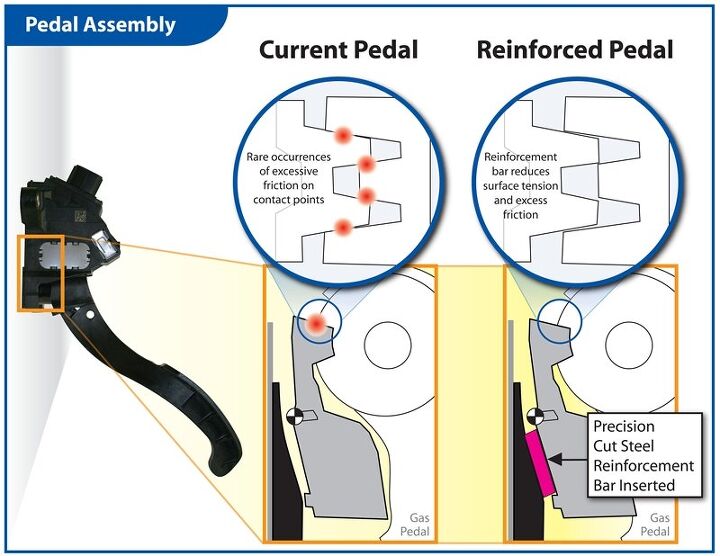

The CTS unit is a fundamentally different design. The friction is generated by two “teeth” (A) that extend from the friction arm, and ride in two grooved channels of the housing (B). The friction arm is an extension of the pedal itself, and moves as the pedal is moved. Both the friction arm, its teeth and the surface it rubs against are plastic. Notice the small area of contact (dulled gray spot on tooth). This is the fundamental source of the problem with this unit, and one that Toyota has not come clean about. The friction unit assembled, showing the teeth engaged in the two grooves, is shown below.

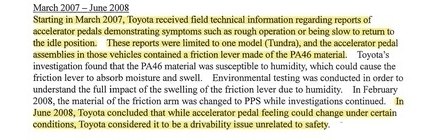

In Toyota V.P. Jim Lentz’ appearance on the Today show, he claimed that issues with the friction arm go back to only October of 2009. Not so. According to a letter from Toyota to the NHTSA , in 2007 Toyota changed the plastic material used in the friction arm (from PA46 to PPS) in response to problems similar to those occurring now.

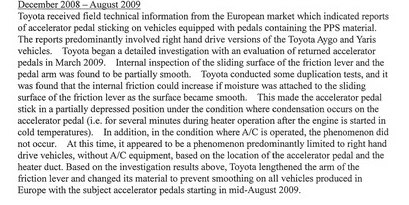

Furthermore, Toyota has been facing similar issues in Europe going back to 2008:

Toyota has been modifying the friction-arm (CTS) type assembly since 2007. Yet to our knowledge, the Denso design has never been implicated in any sticking-pedal issue, and has presumably been in production for some ten years. Why didn’t Toyota change over years ago?

Toyota claims it now has the solution to the pedal problem. Later this week, Toyota will be sending shims that will be inserted under the friction arm of the CTS-built pedal to reduce its tendency to stick. We understand how this fix will work, and have replicated it. It does reduce the degree of friction; the exact amount will depend on the height of the spacer. Our one-eighth inch spacer made a fairly dramatic difference in subjective friction, but we could not test it installed in a car to see how different it would feel on the road.

Regardless of the thickness Toyota chooses for the shim, real and perceived friction will by necessity decrease to the detriment of pedal feel. The original designed degree of friction was obviously chosen to maximize the balance between the two forces at play; any change can only deviate from that, and away from that original ideal balance. We believe the odds are high that drivers will feel the difference, and that some or many may not like it.

Furthermore, the CTS-built unit is prone to continual wear and change in friction level over the long haul. I do not claim to be an expert, but having two small plastic surfaces rubbing against plastic does not strike me as an elegant, reliable or durable design, and one that is presumably subject to long term deterioration from natural and unnatural causes. There are a lot of twenty and thirty year-old Toyotas on the road. But it’s difficult to imagining this assembly still functioning as intended that far down the road, nevertheless even five or ten years from now. Toyota’s well-documented de-contenting is graphically on display here. Yet Toyota is apparently staying with this design, with some further modification, for ongoing new car production.

Whereas the Denso unit (above) is not exactly inspiring in solidity of its all-plastic design and build, it seems to lack the most serious flaw of the CTS unit. The smooth metal coils rubbing against the plastic housing seems less prone to deterioration and change in friction level. There are no known issues or problems associated with it.

We are calling on Toyota to replace all CTS-friction arm type gas pedal assemblies with either the Denso unit, or another proven design that lives up to Toyota’s legendary quality and the longevity expectations of its loyal owners. “Propping up” an intrinsically inferior and historically-proven inferior design with a piece of metal stamping is not going to restore Toyota’s tarnished reputation. The two units are interchangeable; Toyota should do the right thing and switch production over, and insist on replacing all the CTS-type units even after they have had their temporary fix. A Band-Aid will stop the hemorrhaging for the moment, but nothing less than a transplant will do for the long haul.

More by Paul Niedermeyer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Lou_BC Honda plans on investing 15 billion CAD. It appears that the Ontario government and Federal government will provide tax breaks and infrastructure upgrades to the tune of 5 billion CAD. This will cover all manufacturing including a battery plant. Honda feels they'll save 20% on production costs having it all localized and in house.As @ Analoggrotto pointed out, another brilliant TTAC press release.

- 28-Cars-Later "Its cautious approach, which, along with Toyota’s, was criticized for being too slow, is now proving prescient"A little off topic, but where are these critics today and why aren't they being shamed? Why are their lunkheaded comments being memory holed? 'Who controls the past controls the future. Who controls the present controls the past.' -Orwell, 1984

- Tane94 A CVT is not the kiss of death but Nissan erred in putting CVTs in vehicles that should have had conventional automatics. Glad to see the Murano is FINALLY being redesigned. Nostalgia is great but please drop the Z car -- its ultra-low sales volume does not merit continued production. Redirect the $$$ into small and midsize CUVs/SUVs.

- Analoggrotto Another brilliant press release.

- SCE to AUX We'll see how actual production differs from capacity.

Comments

Join the conversation

The transmission disengaged itself while driving as if it had shifted itself into neutral, and only re-engaged after I pulled over, turned the ignition off and restarted. online car insurance quote

The precise Denso buckling spring design is similar to the original tactile IBM mechanical keyswitch modules. I noticed some serious flaws with CTS: 1. Over reliance on inconsistent plastic to plastic sliding friction under pressure for travel control; spring tension for recoil against the same resistance. 2. Excessive surface area of contact exposed between crude plastic teeth & grooves. 3. Similarly oriented dual springs prone to catch without separator. Denso relies more on the buckling spring mechanism than friction for both apply & release travel. The tiny metal protruding guides around the path of the springs are to deliver smooth feel & calibrated feedback. The springs are also counter-oriented relative to each-other with a curled separator in between. Toyota’s shim is a cheap hack that increases spring tension with the effect of reducing pressure on plastic sliding parts. While it prevents sticking, it also makes the pedal feel even more like a brake, increasing the likelihood of mistakes especially in a panic. Strangely the dealers hook up their proprietary Toyota scanners AFTER reinstalling the shimmed pedal back to “check for correct output signals” from the sensor. Why not BEFORE when to catch the original signal voltages? I guess because they actually apply a software patch on the quiet to change either or both of two related behaviors: 1. With cruise on, resume causes the throttle to depress automatically & the car accelerates dangerously to reach the last set cruise velocity ASAP. Pumping the brake cuts off cruise speed even with wide open throttle (WOT). 2. But under sudden unintended acceleration (SUA) brakes don’t work. Here’s where I think buggy internal code thinks the car is in resume cruise mode & just attempts to cut off cruise speed without attempting to actually stop the car. Simplified example of pseudo code below: IF brake_position = APPLIED THEN IF cruise_control = ON AND cruise_mode in (SET, RESUME) THEN SET cruise_mode = NULL; ELSE IF throttle_position != WOT THEN STOP car; END IF; END IF; So this new patch most likely applies global brake override over any throttle position, intended or otherwise. That is again not without its own consequences. On my next I will try to provide the most practicable recourse for cars stuck with a CTS pedal. Thanks to Paul Niedermeyer for the detailed research on his posts.