Hyundai Motor Group Previews Integrated Snow Chain Tech

Hyundai Motor Group have introduced a novel snow chain that’s integrated directly into the tire. The design allows drivers to deploy the system at the push of a button, allowing drivers to sidestep some of the disadvantages associated with installing snow chains.

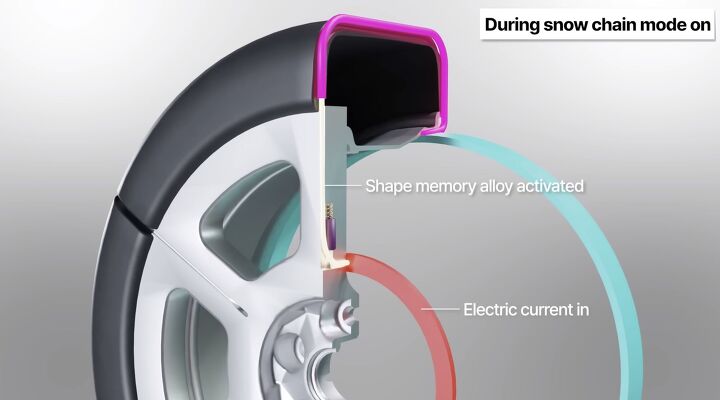

Korean automakers Hyundai and Kia state that the technology relies on “shape memory alloy modules that are located inside the wheel and tire.” While the metallurgy involved can vary, the general premise involves creating an alloy that takes on a fixed shape at certain temperatures and becomes flexible at others. You’ve actually probably encountered shape memory alloys before, as they’re fairly common in medical, dental, and even plumbing applications.

However, advancements in the technology have resulted in companies running an electrical current through the material as a possible alternative to springs and hydraulics. This is also how Hyundai plans on deploying its integrated snow chains, which are actually more like paddles wrapped around grooves that have been cut into the tire.

From Hyundai Motor Group:

The snow chain-integrated tire technology consists of a wheel and tire assembly that feature radial grooves at regular intervals, like a pizza, with modules made of shape memory alloy inserted into these channels.

This technology takes advantage of the shape memory alloy’s ability to return to its original shape when an electric current is applied. During normal driving, the shape memory alloy located inside the wheel is compressed into the shape of the letter ‘L’ and does not contact the road surface. When the driver activates the function, an electric current is applied, causing the shape memory alloy to revert to its original profile; the material forms a ‘J’ shape, pushing the module out of the tire to make contact with the surface, improving grip, stability and safety on snowy roads.

Keeping snow chains on hand is never a bad idea. But actually installing them onto the vehicle is often a miserable task that forces you to scramble on your hands and knees in freezing weather. While certain chains will be quicker to fit than others, most require making adjustments and all of them are likely to result in you becoming colder and wetter than desired.

You’ll also find yourself having to take them off sooner than you’d like, as they’re only suited to clawing through slippery surfaces at low speeds. Snow chains are a liability on clean pavement and are prone toward breaking at speeds above 30 mph. Prolonged use (even at extremely low speeds) will also gradually chew up your tires and mar the pavement.

Hyundai’s concept sidesteps a lot of those issues by having metal paddles that can be deployed or retracted with the simple push of a button. Though we imagine the real trick will be finding a way of having this equipped to vehicles that won’t make tire changes cost a fortune. The shape memory alloy wires need to be embedded into the rubber. But they also have to interact with the vehicle’s electrical system, likely making tire swapping a little tougher than normal. Considering how obnoxiously prevalent tire pressure sensor faults become after vehicles begin to mature, integrated snow chains sound like they could eventually become a headache.

Tire pressure sensors are useful every time you’re driving, making it easier to rationalize the extra maintenance. But snow chains are something most drivers probably won’t need and those that do will only use once or twice per year. Despite being an intriguing concept, reminiscent of the kind of thing you’d see on the Batmobile or whatever James Bond is driving, it might be a tough sell to everyday consumers.

Hyundai says it’s working on that. Tire wear is supposed to be comparable to what’s available today and owners should be able to easily recognize when it’s time to buy some new rubber without special training. Beyond installation, it looks like the company is striving to make the experience identical to owning a set of regular all-season rounds.

“This innovation, which will hopefully be introduced on Hyundai and Kia vehicles someday, reflects our commitment to turning advanced technologies into real-world solutions that benefit customers,” said Joon Mo Park, Head of Hyundai’s Advanced Chassis Development Team. “We will continue to develop technologies that enhance safety and convenience of our vehicles and bring value to our customers.”

The technology is patent-pending in both South Korea and the United States. But Hyundai and Kia say they’d like to field the units on production vehicles once there’s been more development time, some durability testing and the necessary regulatory approvals.

The tires may even be paired to the Uni Wheel concept the Korean automaker presented last month that’s supposed to do away with traditional constant-velocity joints by installing dynamic gear sets inside of the wheel hub. While the mechanical advantages to this seem fairly limited, the concept is supposed to result in a cleaner floorplan that allows for extra cabin space. But I’ve got questions about the utility of having heavy gear sets adding to the vehicle’s un-sprung mass and exactly how Hyundai intends on keeping them lubricated.

It’s another interesting idea from an automaker bent on innovation. But it also sounds too complicated to be a success. Hyundai’s retractable snow chain idea is significantly more appealing and something we’d love to see turned into a commercially viable product someday.

[Images: Hyundai]

Become a TTAC insider. Get the latest news, features, TTAC takes, and everything else that gets to the truth about cars first by subscribing to our newsletter.

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- 2ACL I have a soft spot for high-performance, shark-nosed Lancers (I considered the less-potent Ralliart during the period in which I eventually selected my first TL SH-AWD), but it's can be challenging to find a specimen that doesn't exhibit signs of abuse, and while most of the components are sufficiently universal in their function to service without manufacturer support, the SST isn't one of them. The shops that specialize in it are familiar with the failure as described by the seller and thus might be able to fix this one at a substantial savings to replacement. There's only a handful of them in the nation, however. A salvaged unit is another option, but the usual risks are magnified by similar logistical challenges to trying to save the original.I hope this is a case of the seller overvaluing the Evo market rather than still owing or having put the mods on credit. Because the best offer won't be anywhere near the current listing.

- Peter Buying an EV from Toyota is like buying a Bible from Donald Trump. Don’t be surprised if some very important parts are left out.

- Sheila I have a 2016 Kia Sorento that just threw a rod out of the engine case. Filed a claim for new engine and was denied…..due to a loop hole that was included in the Class Action Engine Settlement so Hyundai and Kia would be able to deny a large percentage of cars with prematurely failed engines. It’s called the KSDS Improvement Campaign. Ever hear of such a thing? It’s not even a Recall, although they know these engines are very dangerous. As unknowing consumers load themselves and kids in them everyday. Are their any new Class Action Lawsuits that anyone knows of?

- Alan Well, it will take 30 years to fix Nissan up after the Renault Alliance reduced Nissan to a paltry mess.I think Nissan will eventually improve.

- Alan This will be overpriced for what it offers.I think the "Western" auto manufacturers rip off the consumer with the Thai and Chinese made vehicles.A Chinese made Model 3 in Australia is over $70k AUD(for 1995 $45k USD) which is far more expensive than a similar Chinesium EV of equal or better quality and loaded with goodies.Chinese pickups are $20k to $30k cheaper than Thai built pickups from Ford and the Japanese brands. Who's ripping who off?

Comments

Join the conversation

Wouldn't Hyundai best apply it's resources to, I dunno, engineering it's engines so they don't go POP within 40k - 60k miles?

The snow chains were covered in Monday's Autoline Daily (skip to 8:16 to watch):

Daily Automotive News (autoline.tv)

As for the Uni Wheel concept, I know it's just a concept right now, but the mechanism looks nightmarishly complex, with a gear train that has to have lubrication, and the mechanical sealing required to allow the hub to move (slide) in relation to the halfshaft, without the grease (gear oil, actually) leaking out. Leaving out the problem of the unsprung mass, which is an issue for ride and handling, requiring suspension parts to be beefier to handle the increased load, this would be a maintenance and repair headache. CV joint technology has improved, and torn boots aren't the problem they were 30-40 years ago. There's nothing wrong with the way things are.

The Uni Wheel was covered on the Autoline Daily from November 29th (skip to 4:52 to watch):

Daily Automotive News (autoline.tv)