IIHS Pressing for Countermeasures Against Horrific Underride Scenarios

In National Lampoon’s Christmas Vacation, Clark W. Griswold road rages his Ford Taurus station wagon under a logging truck to comedic effect. However, without the benefit of movie magic, the following sequence of that film should have been a joint funeral for the entire family. Crash tests conducted by the Insurance Institute for Highway Safety prove that underride accidents are as devastating as they look, and the IIHS is demanding the implementation of every safety solution available.

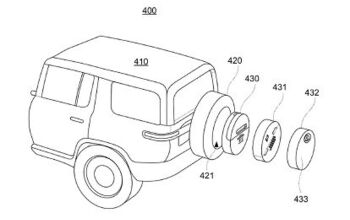

While tractor-trailers are legally obligated to affix underride guards to the rear of their vehicles, the same can’t be said for their flanks. Unsurprisingly, there are more passenger fatalities stemming from incidents where a vehicle strikes the side of tractor-trailer than those where it impacts the rear. Since rear underride guards have proven successful in the lab and on the highways, isn’t it time we utilized similar countermeasures for a truck’s haunches?

“Our tests and research show that side underride guards have the potential to save lives,” says David Zuby, the Institute’s executive vice president and chief research officer. “We think a mandate for side underride guards on large trucks has merit, especially as crash deaths continue to rise on our roads.”

An IIHS study from 2012 determined strong side underride guards have the potential to reduce injury risk in about 75 percent of large truck side impacts — which almost universally result in severe physical harm or fatalities among passenger vehicle occupants. This proportion increased to almost 90 percent when restricted to crashes with semi trailers.

Additional testing conducted this spring, where the IIHS evaluated a side-specific underride guard, highlighted those assertions with some brutal video footage. The Institute ran two crash tests at 35 mph — one with an AngelWing side protection system from Airflow Deflector and a second with a fiberglass side skirt designed solely to improve aerodynamics.

“In both tests, a midsize car struck the center of a 53-foot-long dry van trailer. In the AngelWing test, the under-ride guard bent but didn’t allow the car to go underneath the trailer, so the car’s airbags and safety belt could properly restrain the test dummy in the driver seat,” reported the IIHS. “In the second test with no under-ride guard for protection, the car ran into the trailer and kept going. The impact sheared off part of the roof, and the sedan became wedged beneath the trailer. In a real-world crash like this, any occupants in the car would likely sustain fatal injuries.”

It may not be the single greatest threat facing today’s motorists, but it’s doubtful anyone would be opposed to the IIHS encouraging the usage of well-built side guards on oversized trucks.

[Images: IIHS]

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Probert They already have hybrids, but these won't ever be them as they are built on the modular E-GMP skateboard.

- Justin You guys still looking for that sportbak? I just saw one on the Facebook marketplace in Arizona

- 28-Cars-Later I cannot remember what happens now, but there are whiteblocks in this period which develop a "tick" like sound which indicates they are toast (maybe head gasket?). Ten or so years ago I looked at an '03 or '04 S60 (I forget why) and I brought my Volvo indy along to tell me if it was worth my time - it ticked and that's when I learned this. This XC90 is probably worth about $300 as it sits, not kidding, and it will cost you conservatively $2500 for an engine swap (all the ones I see on car-part.com have north of 130K miles starting at $1,100 and that's not including freight to a shop, shop labor, other internals to do such as timing belt while engine out etc).

- 28-Cars-Later Ford reported it lost $132,000 for each of its 10,000 electric vehicles sold in the first quarter of 2024, according to CNN. The sales were down 20 percent from the first quarter of 2023 and would “drag down earnings for the company overall.”The losses include “hundreds of millions being spent on research and development of the next generation of EVs for Ford. Those investments are years away from paying off.” [if they ever are recouped] Ford is the only major carmaker breaking out EV numbers by themselves. But other marques likely suffer similar losses. https://www.zerohedge.com/political/fords-120000-loss-vehicle-shows-california-ev-goals-are-impossible Given these facts, how did Tesla ever produce anything in volume let alone profit?

- AZFelix Let's forego all of this dilly-dallying with autonomous cars and cut right to the chase and the only real solution.

Comments

Join the conversation

Well I guess with the switch from mid sized cars, this might be a little bit less of an issue for a lot of people ( where is the IIHS's test of a Pickup t-boning a semi trailer? What is the result of this better or worse for the occupants? )

Don't drive under trailers. Problem solved.