Build Your Own Cadillac Sixteen With This 14-liter LS

The Bugatti Veyron Grand Sport Vitesse produces 1,200 horsepower from its tightly packed quad-turbocharged W16 engine. It is a modern marvel that takes four camshafts and 64 valves to move all the air needed to make this power, and it sure doesn’t come cheap.

An oil change for the Veyron costs slightly more than a new Fiesta ST and requires an engine disassembly due to the extremely tight tolerances. We aren’t likely to find a W16 for sale anytime soon and, even if one does pop up, it won’t go for less than six figures. Not to worry, as a company out of Michigan may have a much better solution — one that makes just as much power with half as many valves and no forced induction.

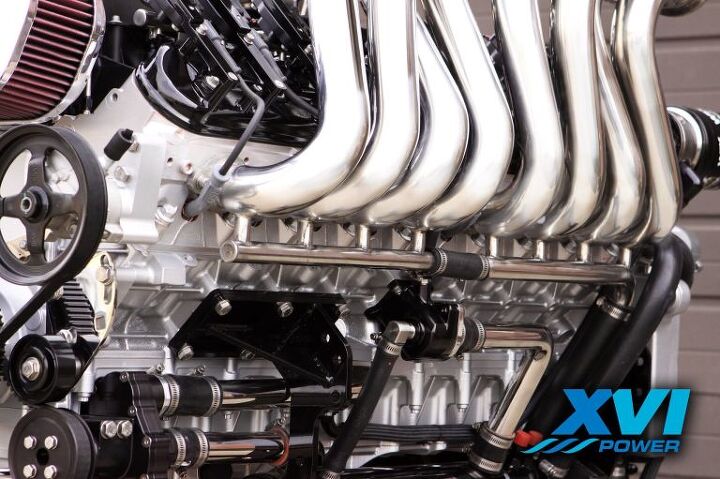

Sixteen Power introduced their new 14-liter V16 engine at the Miami Boat Show last week. The motor is said to be capable of 1,200 to 1,400 horsepower without forced induction and is built on the basis of the LS7. We’ve seen similar V16 builds recently, such as the 4,500 horsepower motor built by Steve Morris Engines for Dubai-based Devel (featuring turbocharging and many one-off parts), but Sixteen Power’s motor is of a different breed. It uses as many off-the-shelf parts as possible and skips many of the costly pieces we’ve seen in previous concepts.

According to Engine Labs, the basis of the motor is the patent-pending M16 engine block, and it is much more than two LS7s welded together. This 16-cylinder block is a Sixteen Power design. It is cast from a single piece of A356-T6 aluminum with a small gap in the middle of deck that allows the company to mount four standard LS3 or LS7 heads on it. This design feature makes the block capable of accepting any off-the-shelf LS3 or LS7 head, which prevents the company from having to cast costly heads that would need to cover eight cylinders on each side. It also allows for upgrades by being able to use any performance version of these heads.

Sixteen Power may be a brand new name in the crate engine world but the people behind it are not. The project was developed by Caleb Newman, who also heads up Performance Design — the company behind the engineering of the V16. The name may sound familiar, as Caleb spent much of the 2000s working for engine builder Katech before starting Performance Design in 2008. He was involved in many LS-based engine projects, such as the mule program for the LS7 when it was in development, along with the engine programs for the C6RS and CTS-V race cars. Just these programs would likely make Newman the best person for the job when developing a LS7-based V16, but the one that ties it all together is his involvement in the Cadillac Sixteen concept.

According to his Linkedin page, Caleb managed the program for the Cadillac XV16 engine used in the Cadillac Sixteen concept car — a program that saw the team design and build the engine in a span of just seven months. The XV16 engine was based on a LS6 design that was customized in just about every aspect (including custom cylinder heads). That engine produced 1,000 horsepower and 1,000 lb-ft of torque and, more importantly, it actually ran and moved the concept car around.

The XV16 did not survive past the show stage, leaving future high-performance Cadillacs equipped with standard LS engines or supercharged Northstars. Fast-forward 15 years and we can see how Newman and his team have used the XV16 as a basis of ideas for their V16 project. The custom cylinder heads, intakes, and valve covers were replaced by standard LS production parts that can be picked up from any GM parts house. The two long headers are replaced by four more standard-looking versions and displacement has increased due to the use of a newer Generation IV LS engine as its base.

Crankshafts need more support as they get longer to prevent them from twisting themselves into destruction, so the Sixteen power team designed a custom one-piece billet unit with larger main bearings. Instead of using the standard LS-sized mains, they opted to go for the larger big block Chevy units and even offer an option to step up further to Duramax-sized ones for forced induction applications. Their crank design is focused on being as stiff as possible and maximizing journal overlap.

Bore and stroke remains unchanged from the LS7 units that it’s based on and provides another set of components that requires little to no customization. The compression ratio is 10.7:1, which is just slightly lower than the 11.0:1 compression ratio of the LS7. The combustion pattern is very similar to the Steve Morris Engines V16 and fires at 45 degrees of every crankshaft rotation to prevent any harmonic issues.

Oiling is performed in a similar manner as the LS7, as the V16 also uses a dry-sump oiling system. It is a bit more advanced than the LS7 unit, as it needs to cover a large area, employing a six-stage pump along with a custom drain-back system for better lubrication. Since this engine is intended for a powerboat application, two-stage water pumps are mounted on each side of the block to provide ample cooling. The whole package amounts to a motor that can produce 1,200 to 1,400 horsepower in naturally aspirated form and in excess of 1,600 horsepower when forced induction is added. The motor is able to spin to 7,000 RPM and should have reliability close to that of an OEM engine.

The engine is targeted at large powerboats which have engine bays that can run as long eight feet, so the four-foot, narrow V16 can fit in there with ease. Installing this engine in a car is a different story altogether, but it’s possible with the right engine bay. The V16 is not much longer than some recent production engines — it’s only about a foot longer than the V10 used in the Dodge Viper — so putting it in a custom car or restomod is possible with some engine bay surgery. The narrow angle and slim front drive help to alleviate some of the space concerns, which allows the dry-sump oiling system to be fitted to most projects.

[Images: XVI Power, General Motors] [Video: Powerboat Nation via Facebook]

More by Bozi Tatarevic

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Redapple2 I gave up on Honda. My 09 Accord Vs my 03. The 09s- V 6 had a slight shudder when deactivating cylinders. And the 09 did not have the 03 's electro luminescent gages. And the 09 had the most uncomfortable seats. My brother bought his 3rd and last Honda CRV. Brutal seats after 25 minutes. NOW, We are forever Toyota, Lexus, Subaru people now despite HAVING ACCESS TO gm EMPLOYEE DISCOUNT. Despite having access to the gm employee discount. Man, that is a massive statement. Wow that s bad - Under no circumstances will I have that govna crap.

- Redapple2 Front tag obscured. Rear tag - clear and sharp. Huh?

- Redapple2 I can state what NOT to buy. HK. High theft. Insurance. Unrefined NVH. Rapidly degrading interiors. HK? No way !

- Luke42 Serious answer:Now that I DD an EV, buying an EV to replace my wife’s Honda Civic is in the queue. My wife likes her Honda, she likes Apple CarPlay, and she can’t stand Elon Musk - so Tesla starts the competition with two demerit-points and Honda starts the competition with one merit-point.The Honda Prologue looked like a great candidate until Honda announced that the partnership with GM was a one-off thing and that their future EVs would be designed in-house.Now I’m more inclined toward the Blazer EV, the vehicle on which the Prologue is based. The Blazer EV and the Ultium platform won’t be orphaned by GM any time soon. But then I have to convince my wife she would like it better than her Honda Civic, and that’s a heavy lift because she doesn’t have any reason to be dissatisfied with her current car (I take care of all of the ICE-hassles for her).Since my wife’s Honda Civic is holding up well, since she likes the car, and since I take care of most of the drawbacks of drawbacks of ICE ownership for her, there’s no urgency to replace this vehicle.Honestly, if a paid-off Honda Civic is my wife’s automotive hill to die on, that’s a pretty good place to be - even though I personally have to continue dealing the hassles and expenses of ICE ownership on her behalf.My plan is simply to wait-and-see what Honda does next. Maybe they’ll introduce the perfect EV for her one day, and I’ll just go buy it.

- 2ACL I have a soft spot for high-performance, shark-nosed Lancers (I considered the less-potent Ralliart during the period in which I eventually selected my first TL SH-AWD), but it's can be challenging to find a specimen that doesn't exhibit signs of abuse, and while most of the components are sufficiently universal in their function to service without manufacturer support, the SST isn't one of them. The shops that specialize in it are familiar with the failure as described by the seller and thus might be able to fix this one at a substantial savings to replacement. There's only a handful of them in the nation, however. A salvaged unit is another option, but the usual risks are magnified by similar logistical challenges to trying to save the original.I hope this is a case of the seller overvaluing the Evo market rather than still owing or having put the mods on credit. Because the best offer won't be anywhere near the current listing.

Comments

Join the conversation

Why not just use a marine diesel? This is a great engineering exercise, though.

Is it seriously that much to change the oil in a Veyron? I mean I know of 20k timing belt services in Ferraris and what not but an oil change? I have often wondered if I could do the timing belt on one of those Ferraris and snag one on the cheap(er). The look on the neighbors faces seeing the Ferrari motor hanging from my cherry picker would almost be worth it.