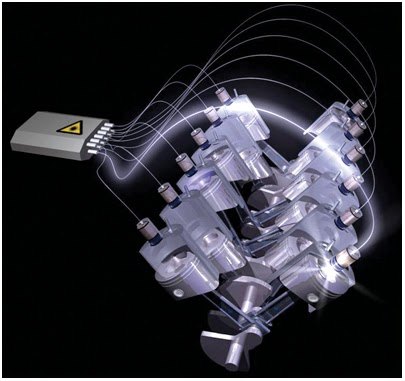

Princeton Optronics' Laser Ignition Could Boost ICE's Efficiency by 27%

A team at Princeton Optronics working on replacing conventional spark plugs with laser igniters has produced a running engine and they claim that replacing spark ignition with lasers could improve the efficiency of gasoline powered engines by 27%. Considering that the basic design of the spark plug hasn’t really changed in over a century, this would be a revolutionary step, frickin’ lasers or not.

While the first spark plug was said to be invented in the 1830s by American Edmond Berger, the first commercially successful spark plug was likely the 1903 Lodge Igniter, invented by Sir Oliver Lodge of the UK. An early advancement, the use of porcelain ceramic as an insulator, is attributed to Henry Ford’s associate and riding mechanic Ed “Spider” Huff. As the story goes, Huff, who had worked with Ford at the Edison Illuminating Co., used toothmaking material from a dentist. Two of the best known American brands of spark plugs were started by the same Frenchman, Albert Champion, a motorcycle racer who supplemented his income selling handcrafted spark plugs to his fellow racers. Champion moved to Flint, Michigan to race for a local company and in 1904 he started the Champion Ignition Company. After he lost control of Champion to his backers, with the help of the Buick company in 1908 he started AC Spark Plug Co. (for Albert Champion), which was eventually absorbed into General Motors.

Since then, while the materials used and number and layout of electrodes have changed, the way the fuel/air mixture has been ignited, with a high voltage current jumping a gap between two electrodes, causing a spark, has not. While it has worked well enough for over 110 years, there are some drawbacks to spark ignition. One of the better known phenomena is the fact that due to the spark plug’s location on the periphery of the combustion chamber, not all of the fuel is combusted. The flame simply doesn’t spread fast enough to keep up with the movement of the piston. The result is less than ideal from power, efficiency and pollution standpoints.

Working under a modest $150,000 contract from the U.S. Department of Energy’s ARPA-E program, Princeton Optronics, a Trenton, New Jersey firm, has demonstrated a working gasoline engine fired with laser ignition. In addition to being able to focus the laser so that it ignites the charge from the middle of the combustion chamber, laser ignition can be timed with greater precision than a conventional spark ignition. It can also cycle faster than the fastest electronically triggered spark plug, allowing for the possibility of multiple firings and those multiple ignitions can be focused at different parts of the combustion chamber to ensure complete burning. Princeton Optronics says that the running engine showed a 27% improvement in combustion efficiency. They also say that the use of laser ignition will allow for a leaner fuel/air ratio, which will reduce emissions.

Back in 2011, Toyota announced that they were working on a laser ignition system, but they never demonstrated a working prototype. Princeton Optronics showcased their own system at an energy innovation summit in Washington, D.C. last week sponsored by ARPA-E. The company demonstrated that their system is capable of withstanding the heat, pressure and high RPM found in a gasoline fired internal combustion engine. While it has yet to be proven to be practical under the hood in automotive applications, Princeton Optronics has already been contacted by a ship company about retrofitting the engines on some of their boats. The shipping industry has come under pressure to clean up their hitherto mostly unregulated emissions. Working under a Navy contract, Princeton Optronics is also working on implementing laser ignition for aircraft engines, where reliability is a critical factor.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can get a parallax view at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks for reading – RJS

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Peter Buying an EV from Toyota is like buying a Bible from Donald Trump. Don’t be surprised if some very important parts are left out.

- Sheila I have a 2016 Kia Sorento that just threw a rod out of the engine case. Filed a claim for new engine and was denied…..due to a loop hole that was included in the Class Action Engine Settlement so Hyundai and Kia would be able to deny a large percentage of cars with prematurely failed engines. It’s called the KSDS Improvement Campaign. Ever hear of such a thing? It’s not even a Recall, although they know these engines are very dangerous. As unknowing consumers load themselves and kids in them everyday. Are their any new Class Action Lawsuits that anyone knows of?

- Alan Well, it will take 30 years to fix Nissan up after the Renault Alliance reduced Nissan to a paltry mess.I think Nissan will eventually improve.

- Alan This will be overpriced for what it offers.I think the "Western" auto manufacturers rip off the consumer with the Thai and Chinese made vehicles.A Chinese made Model 3 in Australia is over $70k AUD(for 1995 $45k USD) which is far more expensive than a similar Chinesium EV of equal or better quality and loaded with goodies.Chinese pickups are $20k to $30k cheaper than Thai built pickups from Ford and the Japanese brands. Who's ripping who off?

- Alan Years ago Jack Baruth held a "competition" for a piece from the B&B on the oddest pickup story (or something like that). I think 5 people were awarded the prizes.I never received mine, something about being in Australia. If TTAC is global how do you offer prizes to those overseas or are we omitted on the sly from competing?In the end I lost significant respect for Baruth.

Comments

Join the conversation

My cat is only 5% more efficient since the conversion. And he's getting fat since he doesn't actually have to chase the mice anymore.

Saab, quite a few years back, had a prototype where the spark plug ground was a nub in the center of the piston. This would allow ignition to start right in the center of the cylinder, and would be less prone to fouling. The challenge is the constantly changing spark plug gap, both through wear and through piston motion. I imagine electronic controls and a sufficiently powerful spark would make this practical now days though. It seems to offer many of the advantages this system offers while be less susceptible to carbon fouling.