Alternative Technologies: The Power Of Steam

The verdict is in. After two popular articles on the inner workings of the transmission, it is clear that TTAC loves technical articles about complicated mechanical devices. Always one to try to get into the middle of the latest fad, I thought that maybe I too could use my own hard won technical knowledge to write an informative article. The problem is that the only thing I really know how to work on involves technology that is seldom seen in cars these days: steam.

Many people think the days of steam power has come and gone but the truth is that it is still with us. It’s true that the immense locomotives that once thundered across our great land, pistons pounding wildly as they flung themselves along the rails at speeds that often exceeded 100 mph, have all but disappeared, but the reasons for their demise have little to do with the efficiency of their power plants. No, the steam locomotive was undone by the fact that most of them were one-off creations, each one of which required specially constructed parts and that, when General Motors finally began to apply the miracle of standardized parts and the production line to the creation of diesel engines, the great beasts were finally driven to extinction. No, steam simply retreated to places where it could be used to its best advantage and where it still works with such efficiency that it is utterly unremarkable.

The power of steam comes from its expansion. To people accustomed to thinking about the automobile, the way steam works can easily be compared to the combustion of gasoline which takes power from a liquid fuel, gasoline or diesel, and then ignites it into a gas which forces a piston to travel downward in a power stroke. In the case of steam power, water is heated under pressure in a boiler until it turns to vapor and is taken from the drum via a series of pipes, scrubbed of its moisture and sometimes superheated, before being released through a nozzle or inlet valve into an area where it can fully expand. That expansion can be used to cause a piston to move through its stroke or a turbine to spin. Of course, this is a simplistic explanation but just to give you an idea of the power available, just understand that water expands into steam at a rate of 1700 to 1, meaning that one square foot of water heated to 366 degrees F at 150psi will expand to 1700 feet of water vapor at Zero psi.

Image courtesy of atdlines.com

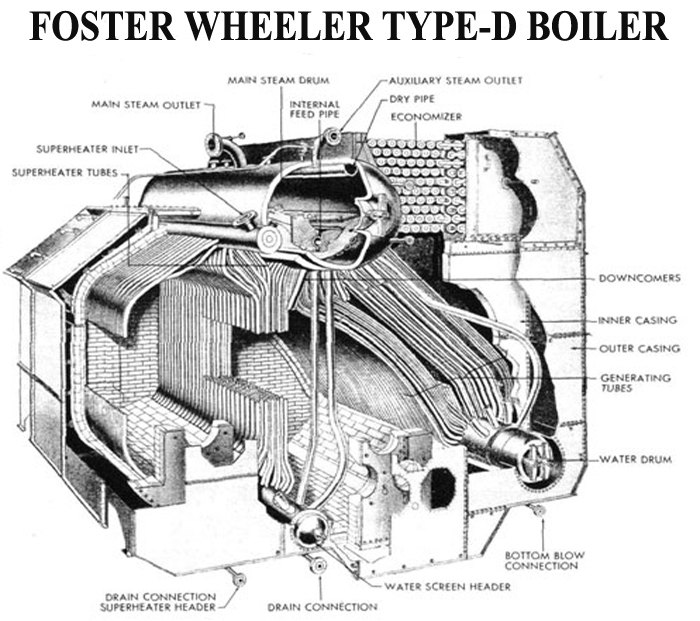

The big, high pressure marine power plants I used to work with were giant systems. The boilers themselves were several stories high, had a firebox big enough for several people to walk around in and thousands of water filled tubes leading into an immense steam and water drum. The steam and water drum mounted several pieces of equipment, including several that were intended to dry the steam so that water droplets could not move through the system and impact sensitive parts downstream, and a superheater to give the steam one last burst of energy prior to its release into a high pressure steam turbine. Once the steam had gone through its initial expansion in the HP turbine, it would then flow into a low pressure turbine where it expended the rest of its energy and then flow into a condenser, basically a big radiator, to condense the steam back into water. That water was then pumped back up to a preheater which brought it back up to temperature so it could be re-injected back into the boiler.

For the most part, boiler water is recovered by the system and never really allowed to cool much below the boiling point. Once the system is up and running the energy demands are not really outrageous considering the amount of power generated and the good news is that the boiler will run on the worst kinds of fuel so long as it is liquid enough to inject into the firebox and burns well enough to make heat.

Of course, a ship’s engine room has a lot of other things going on to support the process I’ve just described. Some parts of the steam are siphoned off to run the high speed, high pressure feed pumps required to inject the feed water into the boiler at the beginning of the process and still more is taken to run other systems like the fuel heating systems and the evaporators that ships use to turn sea water into fresh water. The result is a space crammed full of machinery and a maze of pipes, many of which that are hot enough to burn you right through your boiler suit should you happen to brush up against them in the wrong place.

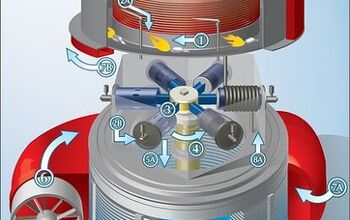

The steam and water cycle of a steam piston engine is much the same as what I have described above for the steam turbine. Water is heated in the boiler, run through the pipes and recovered in the form of condensate the exact same way. The difference is the where it is allowed to expand and how the energy is drawn from it, this time into a piston rather than a turbine.

Most steam piston engines are two strokes, meaning that they only have power and exhaust strokes because the gas being used does not require and induction or compression stroke. Steam is released into the chamber where it expands and forces the piston to the bottom of the stroke. The exhaust stroke is completed by injecting live steam on the bottom of the piston through a second set of intake valves and forcing it back to the top of its stroke, in what is called a “double action.” The advantage to this system is that every time the piston moves it is making power. That power is put to the ship’s propshaft or the locomotive’s wheels by a transmission in much the same way it would be with a gas or diesel engine. The exhausted steam is then recaptured in the form of condensate and then reintroduced to the boiler where it can repeat the process.

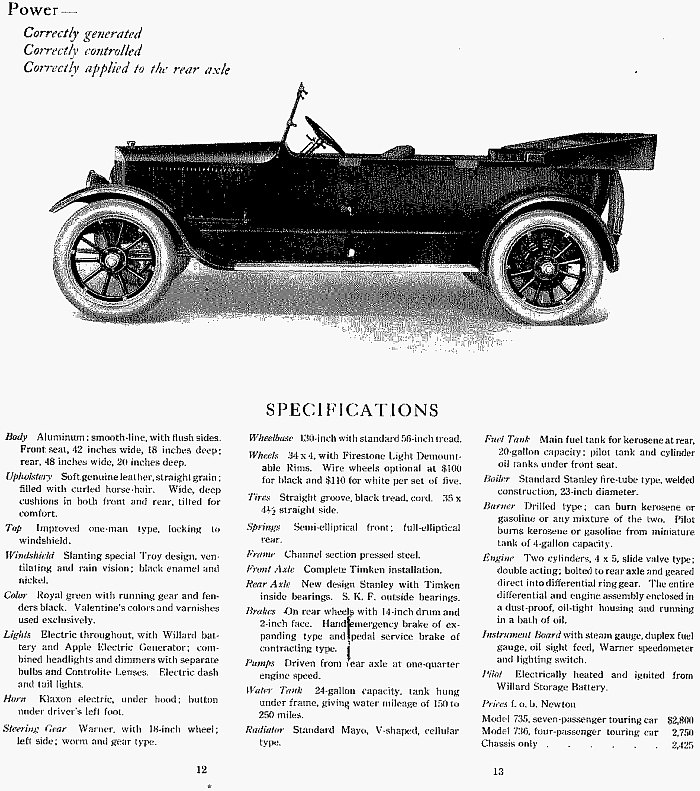

The most famous application of the steam engine to the automotive world is the Stanley Steamer. That vehicle, which was for a time the fastest in the world, utilized a simple boiler and a steam piston engine that featured two cylinders. Produced in various sizes for almost 25 years the design was a great success. The engines were rated by their steaming capacity at 10, 20 and 30 horsepower but had they been rated at their actual numbers produced at their cranks the 20 hp variant would have produced a solid 125 horses.

Image courtesy of stanleymotorcarriage.com

Although it is easy today to look back at the Stanley Steamer as some sort of quaint attempt to marry the newly developing modern age with the Victorian era, the truth is that these were well built, high powered cars that were well regarded in their era. The technology was and is solid and, were it not for the lengthy start-up times due to the need to bring the boiler up to temperature in order to initiate the process, I think it would still do well on the road today.

In the years since the Stanley Steamer left the road and steam locomotives left the rails, marine steam powerplants continued to develop and some of the problems that the early boilers faced were eventually overcome by technology. Things like automated feedwater controls, devices that ensure the boiler water isn’t over or under filled, and reliable relief valves, valves that activate in emergencies to release pressure and prevent boiler explosions, have made the highest pressure boilers safe and easy to use and it seems to me that, today, given the willingness of people to plug their car into a wall socket, that the steam car could make a quick comeback by using electricity to maintain the boiler temp while the car isn’t in use.

Today, almost a century after the car settled into the recognizable form that it has taken today, the need for greater efficiency is driving new innovation. New types of cars are being developed every day and in our rush to embrace the alternative technologies of future I think the potential of steam power deserves a second look as a well. With so many new manufacturers looking to capitalize on bygone glories, perhaps one day soon we’ll have a new version of the Stanley Steamer back on the road.

Thomas Kreutzer currently lives in Buffalo, New York with his wife and three children but has spent most of his adult life overseas. He has lived in Japan for 9 years, Jamaica for 2 and spent almost 5 years as a US Merchant Mariner serving primarily in the Pacific. A long time auto and motorcycle enthusiast he has pursued his hobbies whenever possible. He also enjoys writing and public speaking where, according to his wife, his favorite subject is himself

More by Thomas Kreutzer

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Theflyersfan Non-performance models, probably the Civic based on the fact the interior feels and looks better in the Honda. Both of them are going to drive like adequate appliances with small engines and CVTs and get decent mileage, so this is based on where my butt will rest and things my hands and fingers will touch.Toyota doesn't have an answer to the Civic Si so the Honda wins by default.CTR vs GR Corolla. One dealer by me is still tacking on $10,000 markups for the CTR and good luck with the GR Corolla and the "allocation" system. There's that one dealer in Missouri that I pasted their ad a while back wanting $125,000 for a mid-level GR. Nope. But cars.com is still showing markups. Both of these cars will have little depreciation for a while, so the markups equal instant loss. It looks like Cincinnati-area dealers are done with CTR markups. So this is a tough choice. I don't like the Corolla interior. It looks and feels inexpensive. I'm glad Honda toned down the exterior but the excessive wing still looks immature for such an expensive car that 20-somethings likely cannot afford. FWD vs AWD. With price being an object, and long-term maintenance a thing, I'd go with the Honda with a side eye at the Golf R as a mature choice. All with stick shifts.

- ChristianWimmer Great first car for someone’s teenage daughter.

- SCE to AUX Imagine the challenge of trying to sell the Ariya or the tired Leaf.

- Offbeat Oddity I would have to test them out, but the Corolla might actually have a slight edge. I'd prefer the 2.0 in both cars, but to get one in a Civic with a decent amount of equipment, I'd be stuck with the Sport where the fuel economy suffers vs. the Corolla. If the Civic EX had a 2.0, it would be a much tougher decision.

- User get rid of the four cylinders, technology is so advanced that a four litre V8 is possible.. and plausible.. cadillac had a serious problem detuning v8s in the past, now theyre over-revving the fours and it sounds horrible.. get rid of the bosses and put the engineers in the front seat..

Comments

Join the conversation

Regarding the steam engine's two stroke cycle, back in the mid 70s I saw a Popular Mechanics writeup on a new steam car that used the block and internals from an Evinrude outboard motor as its engine since it provided a conveniently sized ready made 3 cylinder 2-stroke. My take is that steam offers efficiency in large scale applications and incredible fuel flexibility but it hits obstacles in packaging efficiency and ease of use. I doubt you could make a steam plant as compact as a Ford Ecoboost 1.0, much less one that could have a car moving in under 30 seconds.

At least the article and the comments are very informative and entertaining . -Nate