For Memorial Day: The Arsenal of Democracy – the Big 3 Go To War

To commemorate Memorial Day here in the US, we’re taking a look at how the American auto industry was mobilized into war production for World War Two. Because that mobilization was so extensive, the conversion to military production so complete, a blog post by it’s very nature cannot really do the subject justice. This is only the most cursory review of the topic, which truly deserves a book length treatment. As a matter of fact, historian Arthur Herman is currently working on a book about the “arsenal of democracy”, American industry during the war.

Herman will have a lot of material to work with.Today we’ll be looking at the role of the Big Three automakers in war production, starting with General Motors.

The amphibious vehicles that GM made included the “Duck”, the GMC DUKW353. The Duck was designed jointly by GMC Truck Engineering and the naval architecture firm of Sparkman and Stevens. It took them only 43 days after the job was assigned and contracts signed to build the prototype. The US Army ordered 2,000 but over the duration of the war GM built over 21,000 Ducks in the Pontiac GMC plant. It served in a list of storied invasions and the design was so durable that Ducks are still in service carrying tourists in a number of locations around the world.

From the General Motors Heritage Collection:

Officially called model DUKW353, 2-1/2 ton 6×6, Amphibious Troop/Cargo Carrier, it was rated to carry 25 men with equipment or 5,000 lbs. on land or 50 men or 10,000 lbs. in water. It was basically a steel boat hull mounted on a GMC CCKW353, 2-1/2 ton 6×6 truck chassis. Powered by the 102 hp GMC 270 inline 6 gas engine, it had a 5-speed manual transmission and a 2-speed transfer case driving all 3 axles. Special equipment included a propeller and rudder under the stern (rear end to you truckers), 3 bilge pumps, an anchor and a rear-mounted winch. A major advantage was that no special preparation was required before entering the water. In 1943, central tire inflation became available to allow the driver to lower tire pressure for better traction on sand or soft soil, using instrument panel mounted controls.

Ducks were first deployed in an amphibious landing on the island of Noumea in the South Pacific in March, 1943. The public first learned of their existence then when photos were published showing them plunging through 15 ft. high surf to reach the beach. Thereafter, Ducks were used in every amphibious operation in both the European and Pacific theaters. The majority of early built Ducks went to North Africa and from there 100 of them invaded Italy. Many were used in the Normandy invasion in June, 1944, and, in March, 1944, 370 helped to move several Allied armies across the Rhine River into Germany after the Germans destroyed the bridges.

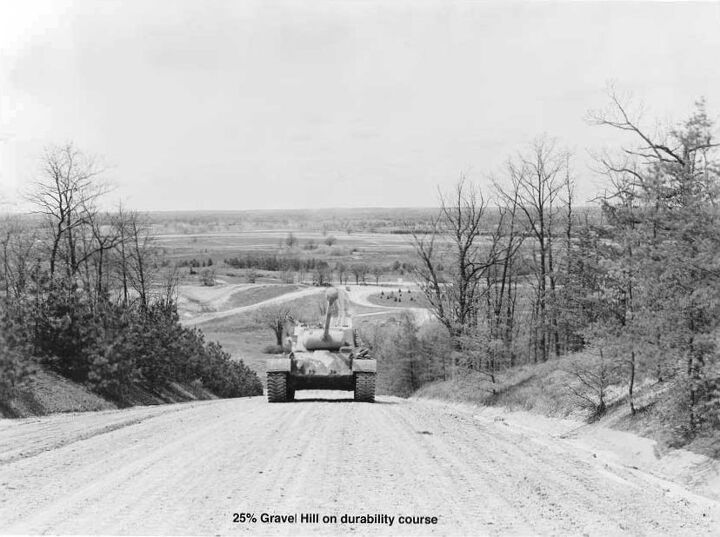

GM didn’t just devote its production facilities to war materiel production. The entire company was mobilized for the war effort. The GM Proving Grounds in Milford, Michigan were used to test a range of military vehicles. Executives like Charlie Wilson and William Knudsen got leaves of absence from GM to run the War Production Board. Knudsen even received a commission as a Lt. General in the Army. His position and contacts in the auto industry proved to be invaluable. His personal contacts with Edsel Ford and Chrysler’s K.T. Keller were instrumental in those companies’ war efforts. As the war’s end drew nearer, Wilson became an advocate for a permanent dedicated defense industry, realizing that the next war would not afford enough time for the kind of industrial conversion the US had undergone. He would further serve his country as Pres. Eisenhower’s Secretary of Defense.

Harley Earl’s styling department also contributed. Art Ross would go on to head styling of Cadillac after the war and then Oldsmobile in the 1950s. During the war he designed military equipment, camouflage and small arms for GM’s Camouflage and War Services Section. Like other GM stylists, he illustrated military instruction manuals. In 1942, he designed and painted a mural in the lobby of the Camouflage and War Services Section, illustrating an enormous tank destroyer that he called the M-1 Hellcat.

It’s not clear if Ross’ design for the “Hellcat” had any influence on the production M-18 Hellcat, but that tank destroyer was built by GM’s own Buick division.

Ross and other members of Earl’s team also did the artwork for “Flight Thru Instruments”, a training manual for pilots. GM’s close involvement with wartime aviation directly led to the P-38 inspired tail fins that GM pioneered in the 1948 Cadillac.

While Chrysler’s contribution may not have been as large as GM’s, in many ways Chrysler was even more influential. Chrysler’s approach to mass producing large weapons systems at the Chrysler Tank Arsenal became the paradigm for other military factories, like Ford’s Willow Run facility, and the dedicated munitions industry that followed WWII.

At this point it should be noted that the automakers and their suppliers did not act solely out of patriotism. At first, before the entry of the US into the conflict, there was money to be made making arms for Britain under the Lend Lease program and for the US government as it rearmed. Once the war started, though, with the evaporation of the civilian market for cars and trucks the American car companies turned to government contracts to stay solvent. Though this was of particular importance to the smaller, poorer independents, the Big 3 could not have stayed in business for the duration had they not gotten contracts to produce weapons.

Still, patriotism was definitely part of the motivation. The Chrysler Corp. took particular pride in the fact that every project that the US government asked the company to perform was performed successfully, on time, below projected costs (Chrysler returned money to the government when efficiencies reduced costs) and beyond expectations.

As early as June of 1940, the Chrysler corporation publicly expressed its desire to start making tanks and other weapons, setting up an ordnance division within the company. Speaking to a convention of Chrysler, Dodge and Desoto dealers Chrysler chairman K.T. Keller boasted that Chrysler would be able to supply all of the US Army’s predicted needs for trucks and reconnaissance cars. Chrysler engineers predicted that the company would be able to start mass producing light tanks within weeks of getting armament contracts. After some initial contracts for bomb noses, shell casings and cartridge cases, later that summer the New York Times reported that the Army was negotiating with both Chrysler and GM for the construction and operation of two tank plants. While the plants’ location near Detroit seems natural due to the companies’ location, concern over possible air attacks on the east coast also argued in favor of the midwest.

In August of 1940 it was announced that American tank manufacturers would be filling a $200 million contract to supply 4,000 tanks to Great Britain. At the same time it was revealed that the US government would have Chrysler build a tank plant, with a 4% margin for building the factory and the same profit margin on the tanks. Chrysler engineers and managers predicted that it would take a year to build the factory and that it would be able to manufacture five tanks a day. Both of those predictions grossly underestimated the company’s ability. The plant would be in operation within 8 months and by the end of the war, Chrysler would be building almost 20 tanks a day. Later it was announced that the plant would cost $20 million to build (~$307 million in 2010 dollars). The contract also included $34 million for tanks. After construction in Warren, Michigan the government took ownership of the plant, known as the Chrysler Tank Arsenal which Chrysler operated under the terms of the contract and leased for $1 a year. The car companies were concerned over appearances of profiteering. Chrysler VP Herman L. Weckler explained that though the company had been asked to manufacture everything from tiny time fuses to 25 ton tanks, they didn’t have the appropriate specialty machinery, which required a substantial investment that had to be amortized.

That machinery was slow in coming. Though the company had no problems with supplies in 1940, with an active war in Europe and so many American industrial firms supplying both Lend/Lease and the US military, it got harder and harder to get machine tools and raw materials. By Feb. of 1941, only a third of the plant’s machinery had been delivered. Only half of the undelivered machinery was scheduled to arrive on time to start production per the timetable. The problem was the government’s Office of Personnel Management and the Army and Navy Munitions Boards’ method of allocating material.

In a frequently told story, K.T. Keller described how Chrysler got into the tank business. William Knudsen had invited him out to his home on Grosse Isle and asked Keller, “Will you fellows build tanks?”.

I said we would. And the next Tuesday, by appointment, I saw him in Washington and after about fifteen minutes of conversation agreed that we would build. Then came a session with the technical men of the War Department, next a visit to the Rock Island arsenal and a ride in a tank which astonished by its riding qualities in rough country.

We came home with 196 pounds of blueprints. It took 197 men four weeks to analyze the whole building and production layout and cost about $100,000.

We made each piece of the tank out of wood in our pattern shop and painted the pieces. We then put the whole tank together without scratching a bit of paint, a tribute to the splendid design work of the Army men who laid out this extraordinary vehicle, which has everything in it from a locomotive to a Swiss watch.

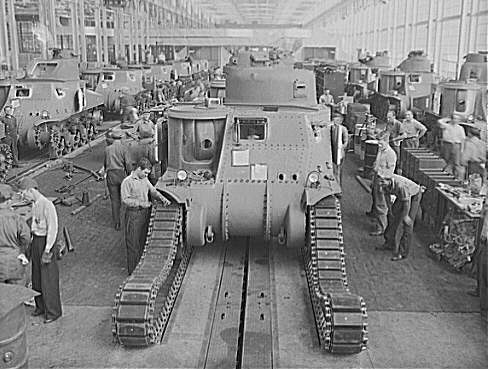

Those patterns were based on the M2A1 tank and the work was done at Chrysler’s Conner Road plant. Soon, though, the M2A1 would be declared obsolete. The arsenal would build the new M3 tank.

By the spring of 1941, the auto industry saw the writing on the wall concerning civilian car production. In April GM announced that there would not be a 1943 model year. Ford and Chrysler would soon follow with the same announcement. Keller said, “We have been so busy with defense work that we have not had a chance to think about 1943 models. We have not got our 1942 models out yet.” Remember, this was still months before the Japanese attack on Pearl Harbor. Still, the Germans did not believe that the US could arm itself quickly and foolishly declared war on the US after the attack. By the time the US was an active combatant, much of American industry had spent the previous two years switching to military production. The US may not have been ready, but it was well on its way, with weapons in production and more advanced planes, tanks and other war machines on the drawing boards. Many of the most iconic weapons used by the US like Sherman tanks, the jeep, the M1 Garand semi automatic rifle our heavy bombers like the B-17, B-24, and even the B-29 were designed before the war.

The first prototype M-3 rolled off the assembly line at the still yet uncompleted arsenal on April 24, 1941. Production started in July, with 7 tanks built that month. Production would ramp up quickly. By the end of 1941, the arsenal would have three production lines and over 6,000 employees and had assembled 500 tanks. Over the next four years, the plant would produce over 3,300 M-3s, almost 15,000 M-4 Sherman tanks and over 7,000 Pershings. The Chrysler Tank Arsenal proved that tanks and other large weapons systems could be mass produced. Though other companies, like General Motors, built tanks for the US and the Allies, Chrysler alone exceeded German tank production. In addition to underestimating the US’ capacity to switch to military production, the German high command assigned much tank production to heavy equipment manufacturers. Building six cranes a year is not the same as building millions of cars. The US built about 75,000 tanks during WWII. The Germans only built about a third that number. Though the German Tiger and Panther tanks had better armor and better guns, the Allies were able to use the Shermans’ speed, mobility and greater numbers, along with close air support, to defeat the German armor.

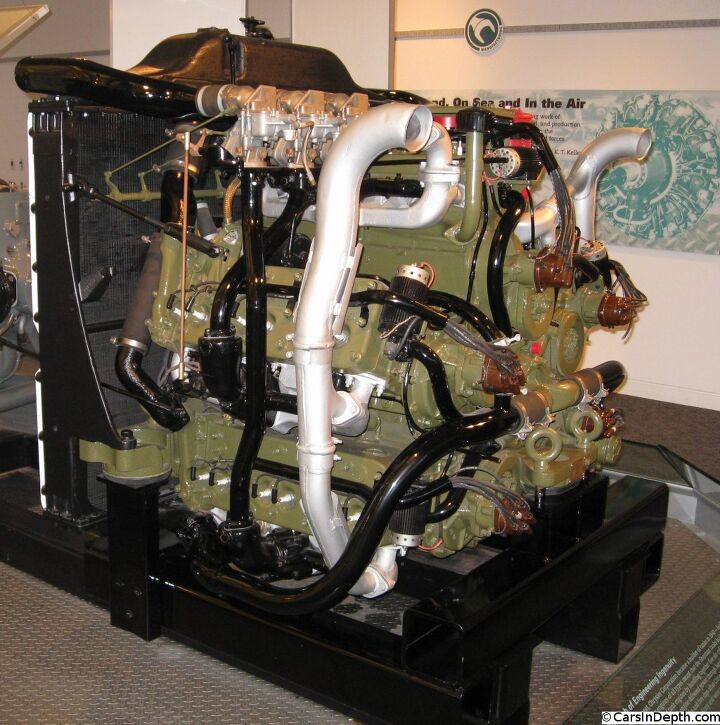

When the M-4 Sherman was being designed, Chrysler engineers had a problem. They didn’t have a suitable engine. Ford proposed an all-aluminum DOHC V16, and the M3 used a radial engine but the Chrysler team instead opted for an unusual but clever in-house solution. Taking five inline Chrysler 6 cylinder engines and mounting them around a central shaft driven by gears on each bank’s flywheel, they developed a massive 30 cylinder, 470HP engine. The primary development issue was induction. The unusual arrangement made it difficult to have equal length runners from the carburetors to the heads. Eventually they worked out that issue and the A57 proved to be very reliable in service. The multibank layout also meant that the engine could still power the tank with as many as two banks out of commission.

Though Chrysler war effort was centered on tank production, it also filled large contracts for 40-millimeter anti-aircraft guns for the Navy, and the Martin B-26 bomber. The company also made refrigerators, bomb fuses, shells, landing gear for airplanes, cartridge fuses, bearings, marine tractors and tugs and assorted military vehicles such as command cars, ambulances, trucks, and weapons carriers for the war effort.

Dodge trucks were an essential part of the famed Red Ball Express that resupplied Gen. George Patton’s Third Army. The Dodge flathead six truck engine proved to be more durable than the OHV “stovebolt” Chevy when running the low octane fuel that was all that was available, the hi-test fuel being reserved for planes. Overall, Patton used more GM trucks but many of them filled the repair depots, with burnt valves.

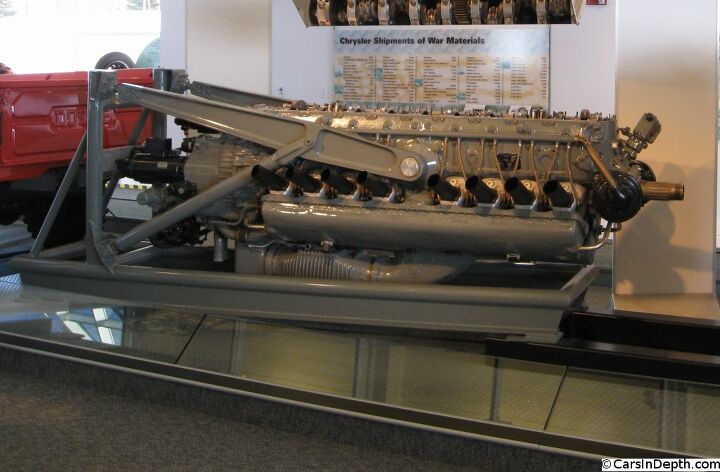

Chrysler tried to get into the airplane engine business, first building a water cooled V12, and then later a V16, an example of which is on display at the Walter P. Chrysler Museum. Though it never saw combat, the V16 was Chrysler’s first use of a hemispherical combustion chamber. Yeah, it’s a Hemi. The cylinder head, crankshaft and connecting rod designs from that engine would later be used in Chrysler’s automotive Hemi. While aircraft engines of Chrysler’s own design did not see combat, under license the company’s Dodge-Chicago plant built thousands of Wright 18 cylinder 2,200 HP “Cyclone” engines for the B-29 Superfortress. The Enola Gay, which bombed Hiroshima, was equipped with Chrysler built engines.

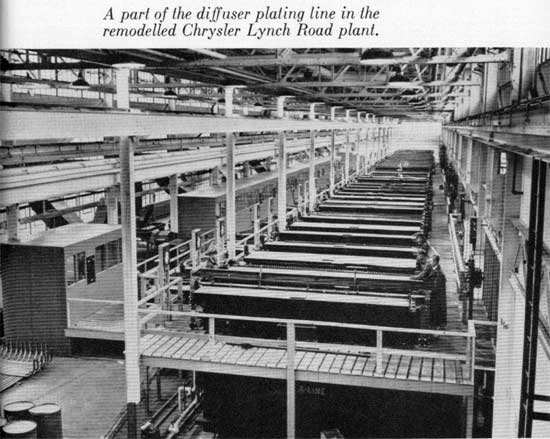

Actually, Chrysler had a much more important role in the race to deliver an atom bomb, a role it earned because of the company’s reputation for engineering excellence. Gen. Leslie Groves, head of the Manhattan Project, needed to separate and purify uranium. The preferred method was gas diffusion, but the uranium hexafluoride gas used in the process is very corrosive. The only thing that would resist it was nickel. Groves turned to Chrysler to make the diffusers. The first challenge was that nickel was in short supply due to its need for other military purposes. The amount of nickel needed for the initial design of the diffusers exceeded the total US supply of nickel. Chrysler engineers determined that the vessels did not have to be made completely out of nickel, that a thin nickel plating not only was sufficient to prevent corrosion and leakage but also plating resulted in purer nickel than machining metallic nickel.

Careful about secrecy, Chrysler transferred thousands of employees from their Lynch Road facility and set up the plating tanks there. To prevent contamination, the facility was air conditioned and clean-room procedures were used. Chrysler also built a processing plant at the Oak Ridge, Tennessee facility of the Manhattan Project, where thousands of diffusers were used to separate the 135 lbs of fissionable material that were used for the Trinity test, and the Hiroshima and Nagasaki atom bombs.

Ford’s role in the arsenal of democracy is pretty well known, due to being able to make one B-24 an hour at their Willow Run factory and also their role in the story of the Jeep. What’s not so well known is that unlike Chrysler, Ford wasn’t exactly eager to get into the weapons business. In a way, Ford Motor Company’s behavior at the start of the Second World War was not unlike Henry’s actions surrounding the first global conflict 25 years earlier. Henry, like Billy Durant at GM, was a pacifist. Ford famously was a passenger on the “Peace Ship”, which futilely sailed to Europe trying to make peace. Later, though, after the US entered WWI, Ford built “Eagle” submarine chaser boats at the Rouge complex. As a matter of fact, initial construction of the Rouge facility and dredging of the Rouge River to accommodate large ships was done under government contract, with taxpayers’ money. When asked about the seeming hypocrisy, Henry Ford explained that though he opposed entering the war he was a patriot who would supply his government once his country was at war. By the time production started, the war was almost over and only five dozen boats were delivered by the end of the war.

In the case of World War I, Henry was a genuine pacifist who didn’t want to take sides. In the case of the second world war, though, Ford may not have been quite as impartial. Adolf Hitler greatly admired Henry Ford. That’s not necessarily to Ford’s discredit as you have no control over who admires you, but Ford also publicly accepted a high Nazi award from Hitler. While Ford might have recoiled had he known of the Final Solution, him not being an exterminationist anti-semite and having cordial relations with those he considered “good Jews”, like Albert Kahn and Rabbi Leo Franklin, he undoubtedly shared some of Hitler’s delusions about Jewish economic power. So Henry was not adverse to doing business with the Third Reich (Ford also did business with Stalin, building Russian car factories in the 1930s).

It should be pointed out that General Motors’ Adam Opel division in Germany also supplied the German government and armed forces in the 1930s. The role of other US companies, like IBM, in Germany in the 1930s and 1940s has been documented. In the case of most of those companies, I believe it was just business. In the case of Ford, though, it’s hard not to suspect that he was sympathetic to the Germans [Note: That link goes to a Christian reconstructionist site which has some fringey posts against flouride in water and in favor of “alternative medicine” AKA quackery, but the Ford article is footnoted from legitimate sources].

By the late spring of 1940, Poland, Norway and Denmark were already under Nazi occupation and France was close to defeat. As Army chief of staff Gen. George Marshall increasingly warned Pres. Roosevelt about the dangers of a German attack on the US east cost, FDR turned to William Knudsen to head military production. Knudsen was president of General Motors but had earlier been a Ford executive. Soon after moving to Washington, Knudsen got an urgent request for warplanes from Britain’s Royal Air Force. FoMoCo having successfully built the Tri-Motor airplane in the 1920s, Knudsen approached Edsel Ford in early June about Ford manufacturing military planes. Edsel agreed that the Dearborn carmaker would expedite production of warplanes for Britain.

On June 12, 1940, Edsel Ford phoned Knudsen to tell him that Ford Motor Company would agree to produce 9,000 Merlin engines under license from Rolls-Royce, 6,000 for the RAF and the remainder for the US Army Air Corps (the USAF did not exist then). When the news of the engine deal came out of Britain, privately Henry flew into a rage. Publicly he repudiated and canceled it, telling a reporter, “We are not doing business with the British government or any other government.” Packard stepped in to make the engines.

Henry lied about not doing business with any other government. According to historian Douglas Brinkley, when Henry said that he’d already agreed to a contract for Ford’s Cologne subsidiary, Ford-Werke, to supply military trucks to the Third Reich. In 1928, Ford had merged his German subsidiary with chemical giant I.G. Farben, which had close ties to the Nazis once they came to power.

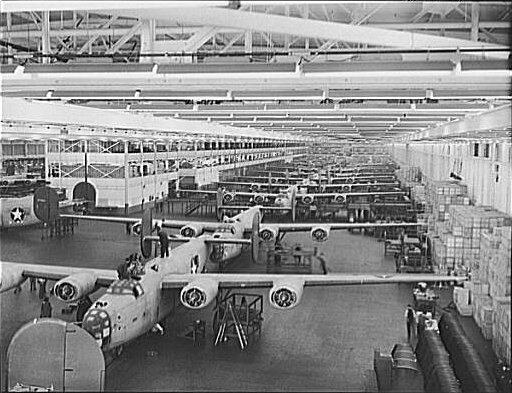

Ford, though, had a good finger on the pulse of average Americans and as with World War One, as US entry into the conflict grew more and more likely, Henry changed his position. Less than a year later, in May of 1941, Ford Motor Company opened up the Willow Run factory for the purpose of building the B-24E “Liberator” bomber. Like the initial construction at the Rouge, Willow Run was also built by the government. In addition to warplanes, Ford produced a variety of military engines, trucks, jeeps, tanks and tank destroyers.

Ford had a major role in the development process for that military jeep, submitting an entrant to the Army’s competition along with American Bantam and Willys. Though the ultimate standardized model was based on the American Bantam design, the Army incorporated Ford’s front end and flat hood (which allowed it to be used to carry cargo or stretchers), and Ford ended up making more jeeps than Willys (the Army decided that American Bantam did not have the production capacity so they were assigned other military contracts). A more detailed version of the jeep history will follow when we look at the role of independent automakers in the arsenal of democracy.

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- MaintenanceCosts What is the actual out-the-door price? Is it lower or higher than that of a G580?

- ToolGuy Supercharger > Turbocharger. (Who said this? Me, because it is the Truth.)I have been thinking of obtaining a newer truck to save on fuel expenses, so this one might be perfect.

- Zerofoo Calling Fisker a "small automaker" is a stretch. Fisker designed the car - Magna actually builds the thing.It would be more accurate to call Fisker a design house.

- ToolGuy Real estate, like cars: One of the keys (and fairly easy to do) is to know which purchase NOT to make. Let's see: 0.43 acre lot within shouting distance of $3-4 million homes. You paid $21.8M in 2021, but want me to pay $35M now? No, thank you. (The buyer who got it for $8.5M in 2020, different story, maybe possibly.) [Property taxes plus insurance equals $35K per month? I'm out right there lol.] Point being, you can do better for that money. (At least the schools are good? Nope lol.)If I bought a car company, I would want to buy Honda. Because other automakers have to get up and go to work to make things happen, but Honda can just nap away because they have the Power of Dreams working for them. They can just rest easy and coast to greatness. Shhhh don't wake them. Also don't alert their customers lol.

- Kwik_Shift_Pro4X Much nicer vehicles to choose from for those coins.

Comments

Join the conversation

GOD BLESS THE BIG THREE. BUY AMERICAN, KEEP AMERICANS AT WORK!!! AND GOD BLESS THE UNITED STATES OF AMERICA.

"the company’s Dodge-Chicago plant built thousands of Wright 18 cylinder 2,200 HP “Cyclone” engines for the B-29 Superfortress." It should be noted that Chrysler just didn't build the things but helped in the engineering of them. These motors had a nasty habit of catching fire early on as well as other problems which the Chrysler engineers helped to solve. http://www.allpar.com/history/military/b-29.html