Entire Universe of Chrysler Products Available For Replacement Headlight Switch On A100 Hell Project

When we last saw the A100 Hell Project, I’d junkyard-engineered a new gas pedal as part of my “get this thing on the road as quickly and cheaply as possible” initiative. The lack of headlights, due to a corroded-by-12-idle-years switch, was the next big annoyance I needed to tackle.

It appears that Chrysler used the same headlight switch for damn near every motor vehicle they built from the time of the Bay Of Pigs to the time of the Iranian Hostage Crisis. The knob changed over the years, but the low-bidder, 11-cent guts remained the same. You can buy new replacement switches pretty cheaply, but I shudder at the certain horribleness of a Chinese-made knockoff of a component that started out as a hammered-together-by-drunks piece of crap. Fortunately, the late-70s camper van that provided the donor gas pedal was still at my local self-service junkyard, so I headed over there. This intriguing business is a block away, so I’ll be paying them a visit soon.

Before I grabbed the switch from this van, I decided to snag the driver’s seat as well; it’s the correct size for the A100 and will serve as a functional butt-rest until I can get the factory seats recovered in red metalflake Naugahyde with maroon piping. You think I don’t have that much style? Think again, sucka!

The original 1966 A100 switch looks like this. No touchy-feely European-style graphic symbols for those who don’t know English here! This one is frozen completely solid; even in Denver’s bone-dry climate, 12 years of inactivity don’t do low-end electrical components any good.

Here’s the switch from the ’78 van. The big “L” has been replaced by a tiny-font “Lights,” but otherwise not much had changed during the preceding 12 years.

Back at my garage, I contemplated just swapping the switches straight across, but I really wanted the headlight switch to match the “W” wiper switch. Knowing Chrysler, there’s probably a Neanderthal method that allowed the Imperial assembly line to swipe switches from over on the Valiant line.

Hmmm… what’s that little button for?

Yep, pushing the button makes it possible to remove the knob and shaft, though not without a lot of persuading and cursing.

And here we go! The quality of the components makes even 60s GM stuff look sophisticated (though, to their credit, Chrysler didn’t use cardboard gloveboxes in their vans), but who cares?

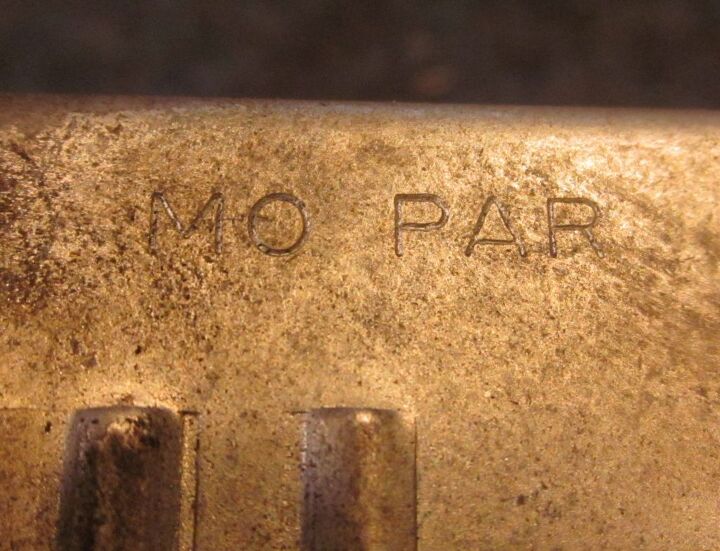

Ever wonder where the term “Mopar” came from? Yeah, we all know, but it’s still cool to see it as two words.

The new switch works just fine. Next step, now that winter is here: fix the heater!

Murilee Martin is the pen name of Phil Greden, a writer who has lived in Minnesota, California, Georgia and (now) Colorado. He has toiled at copywriting, technical writing, junkmail writing, fiction writing and now automotive writing. He has owned many terrible vehicles and some good ones. He spends a great deal of time in self-service junkyards. These days, he writes for publications including Autoweek, Autoblog, Hagerty, The Truth About Cars and Capital One.

More by Murilee Martin

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Lorenzo People don't want EVs, they want inexpensive vehicles. EVs are not that. To paraphrase the philosopher Yogi Berra: If people don't wanna buy 'em, how you gonna stop 'em?

- Ras815 Ok, you weren't kidding. That rear pillar window trick is freakin' awesome. Even in 2024.

- Probert Captions, pleeeeeeze.

- ToolGuy Companies that don't have plans in place for significant EV capacity by this timeframe (2028) are going to be left behind.

- Tassos Isn't this just a Golf Wagon with better styling and interior?I still cannot get used to the fact how worthless the $ has become compared to even 8 years ago, when I was able to buy far superior and more powerful cars than this little POS for.... 1/3rd less, both from a dealer, as good as new, and with free warranties. Oh, and they were not 15 year olds like this geezer, but 8 and 9 year olds instead.

Comments

Join the conversation

My 92 Ford Ranger uses the pull switch as well and also powers the driving lights, when on. There is a separate rocker switch for those, however, Ford wired them to ONLY work with the low beams. That said, Ford now uses a rotary switch in roughly the same position and GM has used and may still rely on push button style switches for their lights. Most others use the turn signal stalk. Now I've never understood why Ford thought it was cool to put the horn on the turn signal stalk on the old Fairmonts, what a stupid idea.

"the quality of the components makes even 60's gm stuff look sophisticated." The shaft looks almost exactly like the headlight switch shafts that gm and ford used. It's not at all unusual that a switch from a 70's van fit your 66. GM, ford and chrysler used lots of parts from the 60's clear into the 80's. Gm and ford even used parts from the 60's that were outwardly visible into the 80's, like window cranks. I owned an 86 F 150 and 89 econloine, both used the same brake pedal pads from early 60's ford trucks and econlines. GM used the same ignition switches from 69 until at least 88 , ford and chrysler did the same. the list goes on. It makes for great parts availability when needed such as in your case.