Outsource to Detroit: GM Workers to Build Hondas Under EV Agreement

Sometimes, if you find yourself lagging behind the pack and eagerly wish for a quick way to catapult yourself ahead, it makes sense to piggyback on someone else’s work. And in the realm of electric vehicles — brow-furrowingly pricey and time-consuming to develop as they are — automakers are coming to the conclusion that perhaps someone else should do the heavy lifting.

Subaru has Toyota, Ford has Rivian (and Volkswagen), and Honda now has General Motors.

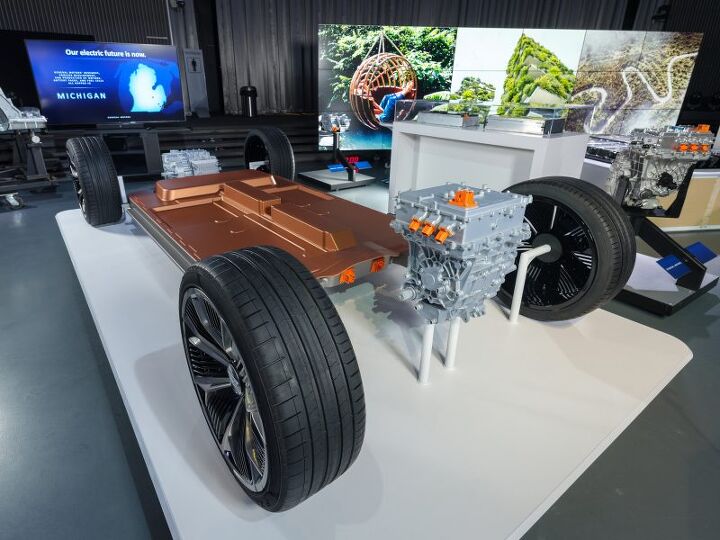

The two automakers announced an agreement late Thursday to partner on two jointly built electric vehicles. The two models will carry the Honda badge, but underneath will sit the modular EV platform unveiled by GM a month ago, paired with the American company’s proprietary Ultium battery technology.

Honda will design the interior and bodywork, while GM workers will assemble the things in a domestic plant. The two models’ customers will be of the North American variety. Arrival date? Sales should begin in 2024, the two said in a joint announcement.

That domestic plant could well be the sprawling Detroit-Hamtramck facility that until recently sat on GM’s chopping block, but is now designated as the automaker’s first all-EV production facility. Michigan’s Orion Township plant also assembles EVs (the Chevrolet Bolt and upcoming Bolt EUV crossover). D-Ham will receive a range of vehicles all based on the new in-house platform.

Of course, GM and Honda didn’t just meet up for the first time before dashing out to the parking lot for a round of whoopie. The two have eyed each other for years. Early last decade came a pact on hydrogen fuel cell development that birthed nothing consumer-friendly on this side of the ocean. Much more recently, in 2018, Honda sank a fair bit of cash into GM’s newly acquired Cruise self-driving arm, with the beginning of this year seeing the fruits of that collaboration. Behold, the Origin.

Honda also signed on to GM’s battery development efforts in 2018.

With Honda lagging in the electric vehicle field, sourcing a platform from GM and building a vehicle at its U.S. EV hub makes more sense than going it alone. Honda-badged EVs will be able to make it to consumers far quicker this way, and at a more attainable price.

“This collaboration will put together the strength of both companies, while combined scale and manufacturing efficiencies will ultimately provide greater value to customers,” said Rick Schostek, executive vice president of American Honda Motor Co., Inc., in a statement.

“This expanded partnership will unlock economies of scale to accelerate our electrification roadmap and advance our industry-leading efforts to reduce greenhouse gas emissions.”

Doug Parks, GM’s global product development boss, said the agreement “further validates the technical advancements and capabilities of our Ultium batteries and our all-new EV platform.”

Honda recently deep-sixed the limited-availability Clarity Electric, an EV version of its more popular PHEV model (and even scarcer hydrogen fuel cell version). That vehicle, available only as a lease to customers in California and Oregon, offered a very affordable monthly fee but could only travel 89 miles on a charge — greatly limiting its usefulness and appeal. A compliance vehicle, for sure, but also a demonstration one. Overseas, the brand stands to gain some green cred when its cute-and-retro Honda E city car goes on sale this summer, but North America remains an electric wasteland for the company, minus some new hybrid efforts.

With GM’s help, that situation will change. After all, you can’t have your main rivals driving away with all the green glory.

It’s worth noting that a platform and battery pack won’t be the only thing shared between the two auto giants. As stated by GM, “Honda will incorporate GM’s OnStar safety and security services into the two EVs, seamlessly integrating them with HondaLink. Additionally, Honda plans to make GM’s hands-free advanced driver-assist technology available.”

[Images: General Motors, Grisha Bruev/Shutterstock]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jimbo1126 $29,995? Chevy boasting that? It still looks like it starts at $19,995 and you know it's true.

- Tassos Money IS no object for me, but I would NEVER live in such a LOSER building.The REAL Tassos.

- Bd2 None of this would have happened had Hillary Rodham become president in 2016.

- Ras815 Jeep reliability is trash and FCA is a nightmare, but I've got to give credit where credit is due: the Wrangler color palette is consistently one of the best in the industry.

- Tassos Jeep has always been about FREEDOM and freedom to EXPRESS YOURSELF. I, REAL Tassos, LOVE this for the brand it’s buyers. I have ordered one already with a matching blue lives matter American flag sticker.

Comments

Join the conversation

"......while GM workers will assemble the things in a domestic plant....". Now what could go wrong with that?

Riding lawn mowers are built this way, it was only a matter of time before the auto companies realized they too can’t afford brand-specific manufacturing.