Tesla Workers Say Almost Half of Model 3 Parts Need Rework

Tesla keeps insisting it’s going to show the automotive industry how to do things differently. The company’s make-or-break Model 3 was put into production without any pilot assembly or validation prototypes. Tesla is also more vertically integrated than traditional automakers these days. It owns its own stores and it makes many of its own parts. So far, with the EV maker as of yet unable to really get mass production underway on the new sedan, the jury is out on Tesla’s strategies.

CNBC now reports current and former Tesla workers saying almost half of the parts made at or produced for the EV startup’s Fremont, California assembly plant don’t meet production standards, forcing rework and end-of-line repairs, as well as impairing morale in the facility.

This raises the question of whether Tesla will be able to mass-produce vehicles in the quantities associated with automotive mass production: hundreds of thousands of vehicles per year. Tesla needs to be able to build and sell its Model 3 at those numbers to be a viable firm.

One Tesla engineer estimated 40 percent of the components used to build Teslas require rework of some kind. Another current employer said that defect rate makes it very difficult to meet production goals. Tesla keeps insisting it will reach a Model 3 production rate of 2,500 a week by the end of March, with that figure doubling by the end of the 2nd quarter of 2018.

Matt Girvan, who advises companies on lean manufacturing at MAG Consulting, told CNBC, “Even during what is considered ‘launch’ mode, if a company is selling its cars to customers, it should not be experiencing large amounts of rework. This speaks to an internal quality issue that is on a magnitude that is not normal for most car manufacturers.”

CNBC also says that to address the problem, Tesla shifted teams of employees from its service centers and remanufacturing lines to assist with repairs and rework at the Fremont factory. It also reportedly sent some defective parts for rework at the company’s remanufacturing plant in Lathrop, California, where used Tesla parts are refurbished.

Tesla categorically denied that its remanufacturing employees were doing any rework on production cars. A spokesman told CNBC, “Our remanufacturing team does not ‘rework’ cars,” and suggested the whistleblowers could be confusing rework and remanufacturing.

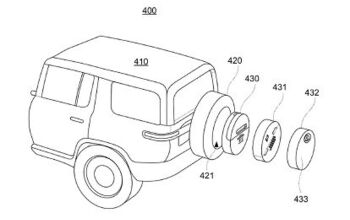

Remanufacturing is the refurbishing of used parts like conventional starters, alternators, and presumably, in the case of EVs, traction motors and battery packs. Rework is taking a production part that doesn’t meet specification and processing it so that it becomes identical to a first run component.

Both of those processes, as well as end-of-line repair, are standard practice in the auto industry, though most automakers outsource remanufacturing and rework. For example, I once saw a few thousand brand new GM V6 engines at a Roush facility waiting to be disassembled because of a defective part. Once taken apart, the still-good components were going to be shipped back to the engine assembly plant for reassembly.

Tesla prides itself in being vertically integrated so it can make a lot of its own parts. Along with other EV makers, they also have to deal with the fact that fewer companies make EV-specific components, compared to those making parts for combustion driven cars, reducing the number of firms capable of remanufacturing or rework.

While Tesla denies it is using its remanufacturing group to alleviate new car production issues, an analysis of job descriptions at the firm shows that the automaker more broadly defines remanufacturing than other industrial companies.

A recent job posting said applicants should have the “ability to identify and analyze new failures [sic] modes from both the field and manufacturing lines,” and a listing for a team process leader in Tesla’s “Vehicle Reman Center” at the Fremont facility said that position would “lead the Value delivery system created to repair and remanufacture Tesla electric vehicles,” and “lead daily operations…on large volume, electric vehicle repair and reconditioning value streams.” Note the use of the word “vehicle,” not “component.”

Tesla says the language in those job posting reflects the fact the company uses information from remanufacturing to improve new car production.

CNBC hired Mag Consulting to analyze Tesla’s remanufacturing job descriptions on its Careers webpage, as well as Tesla listings at LinkedIn and Glassdoor.

Mag Consulting’s Matt Girvan said, “Problems are unavoidable in any factory. ‘Rework’ does happen…These listings speak to what is probably a large amount of product that has either not been built to specification or that has been built to an incorrect specification where the error wasn’t found until later.” Girvan pointed out that, in general, the auto industry’s practice of getting things right the first time avoids the high costs of rework and scrapped parts.

In response to Girvan’s study, Tesla told CNBC, “Remanufacturing is not unique to Tesla, it is something that other manufacturers do too. Remanufacturing involves taking older parts and reconditioning them so they can be used for cars when they eventually come in for service. Rather than making new parts from scratch, this is good for the environment and if done well, is equally good for the customer. Any ‘expert’ claiming there is something unusual about this or that it has something to do with the quality of cars that come off a production line is either very confused or just completely wrong.”

[Image: Tesla]

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- MaintenanceCosts Whenever the topic of the xB comes up…Me: "The style is fun. The combination of the box shape and the aggressive detailing is very JDM."Wife: "Those are ghetto."Me: "They're smaller than a Corolla outside and have the space of a RAV4 inside."Wife: "Those are ghetto."Me: "They're kind of fun to drive with a stick."Wife: "Those are ghetto."It's one of a few cars (including its fellow box, the Ford Flex) on which we will just never see eye to eye.

- Oberkanone The alternative is a more expensive SUV. Yes, it will be missed.

- Ajla I did like this one.

- Zerofoo No, I won't miss this Chevrolet Malibu. It's a completely forgettable car. Who in their right mind would choose this over a V8 powered charger at the rental counter? Even the V6 charger is a far better drive.

- Offbeat Oddity Nope, I won't miss it. I loved the 2008-2012 Malibu, but the subsequent generations couldn't hold a candle to it. I think the Impala was much more compelling at the end.

Comments

Join the conversation

Speaks to the hubris inside the company, thinking that skipping key development phases is optional. This has been thoroughly hashed out by major automakers over the last 100 years. Musk doesn't have a better answer.

Every time there is a quality crisis at Tesla, Musk puts on his spacesuit and heads to Mars. This diversion will only work for so long. The sooner Tesla realizes it is a niche car makers the better things will be. They will never be able to produce 500,000 cars a year. I think Tesla should shoot for 70,000 to 100,000 vehicles a year.