Achates Power Brings an Efficiency Revolution To Detroit

Thus far, the North American International Auto Show has been a truck festival – more specifically, a green-truck fest. Ram showed a hybrid 1500. Ford revealed their V6 diesel. Chevrolet surprised with an inline-six diesel. Clearly the Big Three are looking at the calendar, with a big red circle over the 2025 CAFE standards looming like a dark cloud.

Achates Power, a fourteen-year-old startup from San Diego, has a different idea. By combining a variety of existing technologies – some of which date from before World War Two – they have developed an engine that they expect to meet 2025 fuel economy standards, emissions standards, and most importantly, the performance standards of light-truck buyers.

How does 37 mpg sound in a half-ton truck? That’s on gasoline. The Achates engine can also manage 42 mpg in the same truck running on diesel.

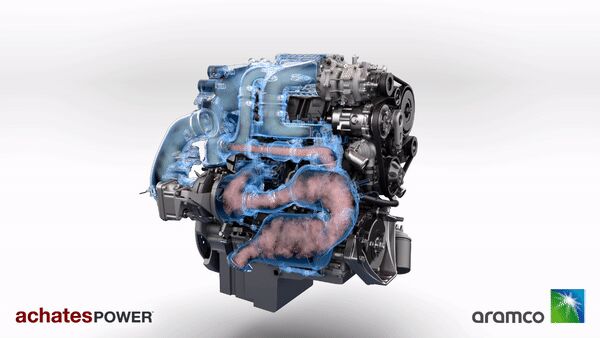

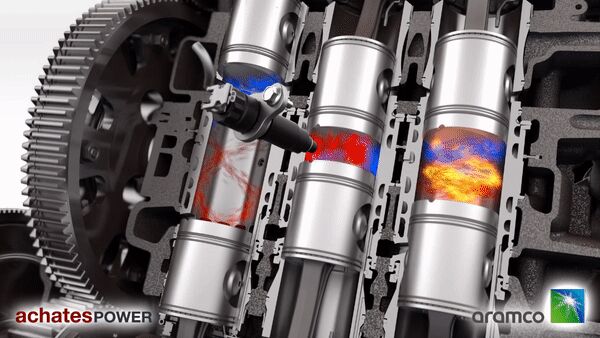

Indeed, the diesel engine is the focus of Achates, while compression-ignition with gasoline is a later development focus. The innovation on this is with the layout of the engine itself. Rather than the typical inline or vee, this engine is:

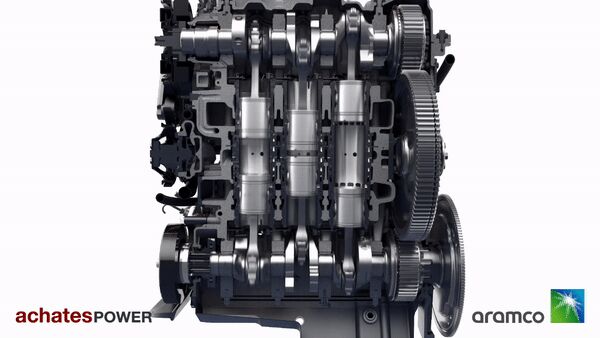

- Three-cylinder

- Six-opposed-piston

- Direct-injected

- Two-stroke

- Turbocharged and supercharged

In other words, a mouthful. As the cylinders are firing toward each other, there are a pair of crankshafts, but no cylinder heads. The lack of a complex valvetrain and cylinder heads will minimize heat and friction losses.

At 2.7 liters, the OP GCI (Opposed Piston Gasoline Compression Ignition) produces 270 horsepower and 480 lb-ft of torque, with a 16.5:1 compression ratio. The diesel version should deliver similar power figures, at 18.5:1 compression.

The Achates Power engine was developed with a $9 million grant from the US Department of Energy.

For the aircraft buffs in the house, this powertrain configuration might seem familiar. Junkers developed an opposed-piston diesel in the 1920s to power various aircraft. It was relatively successful despite the higher relative weight to avgas-powered radial engines.

I’m wondering how the engine will sound. I’m secretly hoping the exhaust note will resemble the two-stroke supercharged Detroit Diesel powerplants known as the “Screaming Jimmy.”

Achates Power announced a partnership with Aramco Services Company here at the 2018 Detroit Auto Show, as the Saudi-based oil company has an interest in making internal-combustion engines sustainable for the foreseeable future. Thus, Achates and Aramco have fitted a diesel 2.7-liter powerplant into a Ford F-150. They assure me that this isn’t a Ford-specific project – indeed, Mark Subramaniam, VP of Business Development for Achates Power, tells me that they have worked with many OEMs on various projects, and are actively shopping this engine technology to many potential partners. They expect to have the engine running and driving in the F-150 later this year.

[Images: © 2018 Chris Tonn; GIFs and truck image courtesy Achates Power]

Some enthusiasts say they were born with gasoline in their veins. Chris Tonn, on the other hand, had rust flakes in his eyes nearly since birth. Living in salty Ohio and being hopelessly addicted to vintage British and Japanese steel will do that to you. His work has appeared in eBay Motors, Hagerty, The Truth About Cars, Reader's Digest, AutoGuide, Family Handyman, and Jalopnik. He is a member of the Midwest Automotive Media Association, and he's currently looking for the safety glasses he just set down somewhere.

More by Chris Tonn

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Bd2 If I had time to watch other people driving, then I would go for LMP.

- Steve Biro There are 24 races on this year’s F1 schedule. And I guarantee you no more than two will be reasonably exciting, Meanwhile, F1’s reception for Andretti reveals the dark underbelly of the sport. I have followed F1 since the 1960s and, frankly, I am running out of interest. I’ll catch a race if it’s convenient but won’t bother DVRing them.

- YellowDuck Been watching since the 80s, seriously since the 90s once we had reliable TV coverage. I'm in Canada though. Hey, and don't forget that the Interlagos race is also in a convenient time zone, as is Mexico. So that's 5 races in the Americas. Absolutely love it, but it takes a bit more interest in the technical / strategic side of things to really appreciate it. It's not just going fast in circles until someone crashes into someone else, while drunk people watch. The US can be proud of what it has contributed - Austin is one of the best tracks on the calendar, Vegas turned out to be much better than anyone could have hoped, and even Miami - a real Indy car-style track - produced a good race this year.

- JMII I watch every F1 race, same with Indycar which is 100X better in terms of actual racing.

- Dale Quelle surprise.

Comments

Join the conversation

This doesn't need pre mixing like a traditional 2 stroke as the crankshaft is like a 4 stroke aka it's not for compressing of the combustion gas. That being said although this won't have the oil consumption issues of a 2 stroke I still think it have issues with oil consumption due to using sleeve valves as the oil control ring pass. There are several video's online that show how it works such as https://youtu.be/2RwqL-7G-3c

There have been a lot of opposed piston engine designs and in recent years I've seen maybe a half dozen different startups using some kind of opposed piston setup. So far none have come to market. Ecomotors looked promising, announced all sorts of deals with Chinese companies and now their website is offline.