Kettering Repurposes Flint's 'Chevy in the Hole' for Autonomous Driving R&D Center

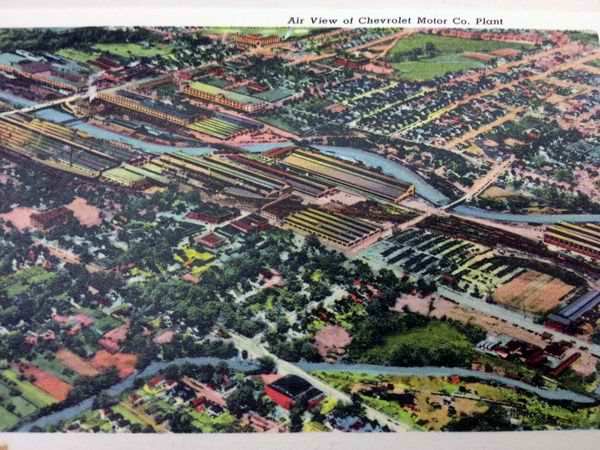

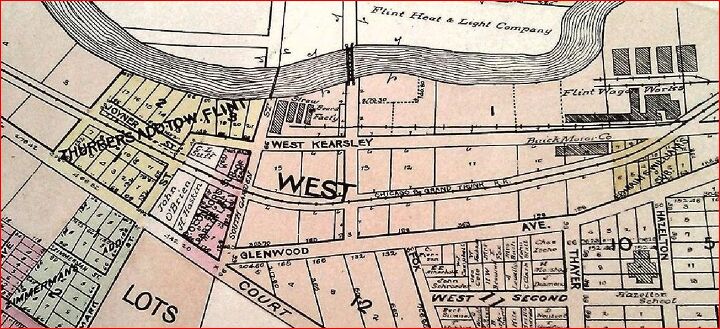

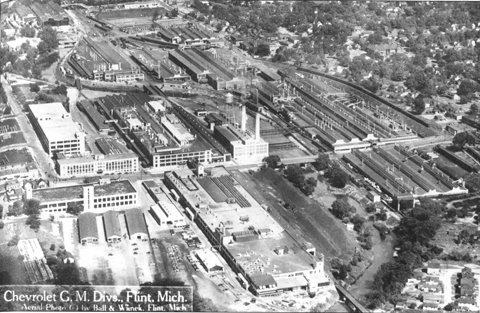

The former General Motors site along the Flint River was officially known as Chevrolet Flint Manufacturing, but many of the folks who worked there and Flint locals called it “ Chevy in the Hole” — likely a reference to its location in the river valley. It was once GM’s most profitable operation, producing millions of Chevys, engines, AC spark plugs and other components that went into those Chevrolets and other GM vehicles. It’s also where the United Auto Workers made history with its massive sit-down strike in 1936-37.

Starting with an engine plant in 1913, GM grew and so did the complex, adding an assembly plant and then a Fisher Body factory in the early years. Eventually the complex’s scores of buildings took up 130 acres. As the American auto industry started its decline in the 1980s, though, and over the next two decades, the massive complex was shut down and taken apart in piecemeal fashion, just as it had been assembled.

Today, only two buildings remain. One is still a GM tool and die shop and the other was donated to Kettering University (formerly the General Motors Institute, GM’s private engineering and business management college). Kettering houses its mechanical engineering and chemistry departments there.

The rest of Chevy in the Hole became a blighted symbol of the Rust Belt. Last year, however, redevelopment of about half of the site into an urban park called Chevy Commons began. Plans include wetlands, woodlands, grasslands and other green areas.

A few weeks ago, Kettering University debuted phase one in a project that’ll turn another 21 acres of Chevy in the Hole into a facility for the research and development of autonomous vehicles. Named the GM Mobility Research Center, the first phase of the project, a 3.25 acre skid pad and outdoor laboratory space, was funded with a $2 million grant from the automaker. The test pad was built to racing industry specifications and includes stadium lighting for nighttime testing. The site is also linked to Kettering’s private high-speed 4G LTE network, allowing for the testing of vehicle to vehicle and other telematic technologies.

Phase two of the facility, scheduled to start construction early next year, will add a low-speed road course and a building that includes indoor labs, conference rooms, and a garage with automotive bays and lifts. A $1.9 million grant from the United States Economic Development Administration to Kettering will pay for that phase of the project.

Like the University of Michigan’s MCity autonomous driving facility in Ann Arbor, Kettering’s mobility research center will be made available for the use of automakers, vendors, and the school’s faculty and students.

Among the dignitaries at the ribbon cutting ceremony was Michigan’s lieutenant governor Brian Calley. The state of Michigan has worked hard to stay in a leadership role in the auto industry as it embraces driverless vehicles. In addition to the two university-based autonomous driving R&D facilities, there is also the state sponsored American Center for Mobility at Willow Run near Ypsilanti.

As with the GM Mobility Research Center and Chevy in the Hole, the American Center for Mobility is a so-called brownfield redevelopment. The 335-acre Willow Run facility was originally built by Ford to manufacture B-24 Liberator bombers during World War II. Later, General Motors built Corvairs and Hydramatic transmissions there.

While the Ypsilanti and Flint research facilities will only employ a tiny fraction of people who worked on those sites when they were factories, they do address urgent needs of the state and its residents. Former heavy industrial sites are often contaminated with chemicals and metals and thus reduce the options of possible redevelopment uses. Autonomous R&D centers can put those sites to good use, removing blights from the landscape while providing resources that will allow the state’s leading industry to thrive as it changes in the 21st century.

[Images: Genesee Valley Historical Society, Kettering University, chevyinthehole.blogspot.com]

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jimbo1126 $29,995? Chevy boasting that? It still looks like it starts at $19,995 and you know it's true.

- Tassos Money IS no object for me, but I would NEVER live in such a LOSER building.The REAL Tassos.

- Bd2 None of this would have happened had Hillary Rodham become president in 2016.

- Ras815 Jeep reliability is trash and FCA is a nightmare, but I've got to give credit where credit is due: the Wrangler color palette is consistently one of the best in the industry.

- Tassos Jeep has always been about FREEDOM and freedom to EXPRESS YOURSELF. I, REAL Tassos, LOVE this for the brand it’s buyers. I have ordered one already with a matching blue lives matter American flag sticker.

Comments

Join the conversation

As for Willow Run, I used to think that Corvairs were built in the former B-24 plant, but that's not the case. Actually, the bomber plant became a Hydramatic transmission plant, after the 1953 fire that destroyed the Detroit Transmission plant in Livonia. Its first automotive use after building B-24s was building Kaisers and Frazers. Corvairs (and Novas for a while) were built at Willow Run Assembly, a separate facility south of the bomber plant. I'm a former Corvair owner, and still a member of the local club. For awhile we had a member who worked at Willow Run Assembly, and built Corvairs. He gave a presentation one month during the program part of the meeting, with his reminiscences of building Corvairs.

They ve been talking about this for a while. Kettering/GMI= the #1 IE program in the world year after year for decades.