Editorial: Get Ready For Massive Recalls Driven By Modular Platforms

Today’s recall announcement by Toyota estimated to span at least 6.4 million vehicles, serves as a nice distraction from the ongoing recall occurring at cross-town rival General Motors. The Best & Brightest are free to squabble about which faceless corporate entity with zero regard for their individual well-being is the superior one. The rest of us have bigger fish to fry.

At 6.4 million vehicles, this Toyota recall is massive. It won’t be the last one. In fact, I think that ten years from now, this will be a low number.

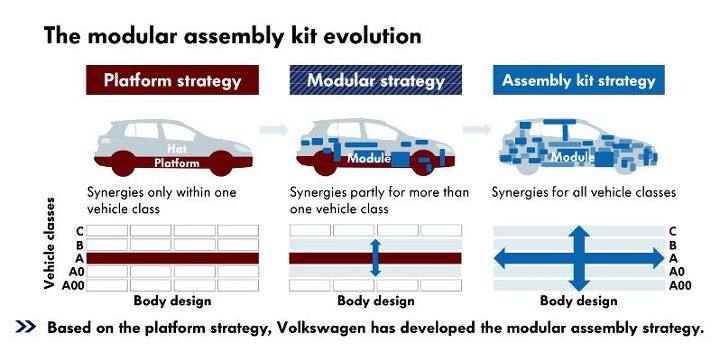

The big trend in the auto industry today is modular platforms, which allow an enormous range of vehicles to share components. Volkswagen’s MQB architecture is an oft-cited example of this, largely because it takes a holistic approach to modularity. Much like Lego bricks, different “modules” can be assembled to create different vehicles. MQB is capable of spawning everything from a B-segment Volkswagen Polo to a D-segment Volkswagen Passat to an Audi TT sports car to a Volkswagen Touran minivan. Only a small number of “hard points” like the dimension from the center line of the front wheel to the pedal box, or the engine mounts, are fixed.

Within these modules are a high level of common parts, designed to be used across the entire range of MQB vehicles. This can include everything from whole powertrains to braking systems to smaller components that could be shared across a range of small to mid-size vehicles – which is, in theory, a truly vast quantity. Other commentators have expressed worries that MQB will lead to components being mismatched to their application. An A/C system engineered for a Passat might be overkill on a Polo (or vice versa) from a utility or financial standpoint.

From a purchasing standpoint, MQB will allow Volkswagen to buy lots and lots of widgets, receiving a significant discount on the cost per widget. This will equal significant savings for VW (though just how much they’ll save seems to depend on who you ask) while leading to shorter assembly times and more standardized production of vehicles. In the event that demand for a given model changes, a factory could scale back production of a slower selling model to help meet demand for the more popular one. This gives Volkswagen unprecedented flexibility in the way that cars can be designed, engineered and manufactured.

It also leaves Volkswagen in a very vulnerable position. What happens if they get a bad batch of widgets from a supplier, or the widget in question was poorly engineered? What if a manufacturing process was poorly designed, and the widgets aren’t installed properly? With so many vehicles assembled with the same faulty part or process, the impact could be enormous: millions of vehicles requiring repair, a black eye for Volkswagen and, heaven forbid, human lives negatively impacted.

This kind of exposure to potential quality defects and mass recalls was dubbed a “Cascading Failure” in a prior article, but many readers with engineering backgrounds objected. Instead, we can call it a “platform level failure”, which is the key difference between the scenario outlined above, and the Toyota recall, which affects everything from the Yaris subcompact to the Land Cruiser SUV.

But in a future where every car maker will have to adopt some kind of modular architecture, the likelihood of these events occurring is almost certain. And those who have invested most in common vehicle architectures are at the greatest risk.

More by Derek Kreindler

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- TheEndlessEnigma These cars were bought and hooned. This is a bomb waiting to go off in an owner's driveway.

- Kwik_Shift_Pro4X Thankfully I don't have to deal with GDI issues in my Frontier. These cleaners should do well for me if I win.

- Theflyersfan Serious answer time...Honda used to stand for excellence in auto engineering. Their first main claim to fame was the CVCC (we don't need a catalytic converter!) engine and it sent from there. Their suspensions, their VTEC engines, slick manual transmissions, even a stowing minivan seat, all theirs. But I think they've been coasting a bit lately. Yes, the Civic Type-R has a powerful small engine, but the Honda of old would have found a way to get more revs out of it and make it feel like an i-VTEC engine of old instead of any old turbo engine that can be found in a multitude of performance small cars. Their 1.5L turbo-4...well...have they ever figured out the oil dilution problems? Very un-Honda-like. Paint issues that still linger. Cheaper feeling interior trim. All things that fly in the face of what Honda once was. The only thing that they seem to have kept have been the sales staff that treat you with utter contempt for daring to walk into their inner sanctum and wanting a deal on something that isn't a bare-bones CR-V. So Honda, beat the rest of your Japanese and Korean rivals, and plug-in hybridize everything. If you want a relatively (in an engineering way) easy way to get ahead of the curve, raise the CAFE score, and have a major point to advertise, and be able to sell to those who can't plug in easily, sell them on something that will get, for example, 35% better mileage, plug in when you get a chance, and drives like a Honda. Bring back some of the engineering skills that Honda once stood for. And then start introducing a portfolio of EVs once people are more comfortable with the idea of plugging in. People seeing that they can easily use an EV for their daily errands with the gas engine never starting will eventually sell them on a future EV because that range anxiety will be lessened. The all EV leap is still a bridge too far, especially as recent sales numbers have shown. Baby steps. That's how you win people over.

- Theflyersfan If this saves (or delays) an expensive carbon brushing off of the valves down the road, I'll take a case. I understand that can be a very expensive bit of scheduled maintenance.

- Zipper69 A Mini should have 2 doors and 4 cylinders and tires the size of dinner plates.All else is puffery.

Comments

Join the conversation

You're leaving out one part of the equation. Sharing same parts among more models means that if the part goes wrong, the recall is larger. But, at the same time, it means that there is less variants of said parts to go wrong. Which means that there will be bigger recalls, but less of them. And it could be argued that since there will be less parts to design, automakers will be able to put more effort into designing each of them, so recalls can, in the end, be more scarce than they are now.

Does it follow that there would be fewer recalls if platforms were not modular? Or is the issue not modular but quality control?