Car Companies, Standard Thyself Or Die

The two-by-four, the 4×8 plywood sheet, the standard brick: Without standardized building materials, building houses would be a mess. The car industry is in that kind of a mess (more or less.) To get out of the mess, to shorten development times and to lower cost, just about every large automaker is on some kind of a standardization drive. Usually, these standards won’t go beyond the company, even alliances have problems agreeing on a common standard. When Nissan unveiled its Common Module Family (CMF) last Monday at its R&D center in Atsugi, we asked whether this Common Module Family also would extend to Renault. After all, both companies had standardized on the same CEO.

We received an evasive answer.

The idea behind standardization is this: Just like houses are built from standard building materials and yet maintain their individual style (unless we have lazy architects,) cars could be designed from standard building blocks. Common platforms were one step in that direction, but it was just a first step on a very long road.

When GM announced its standardization drive last year, it was looking at 30 “core architectures” and a huge number of regional solutions. By 2014, GM wanted to shrink the number of “core architectures” to 24. By 2018, GM wanted to have eliminated all regional architectures and be ready to serve 90 percent of the volume with 14 global architectures. GM is at the very beginning of standardization.

On the other side of the spectrum appears to be Volkswagen with its MQB, MLB etc. kits. Volkswagen is about to take the next step, abandon platforms altogether and instead will design its cars from building blocks with clearly defined measurements and interfaces.

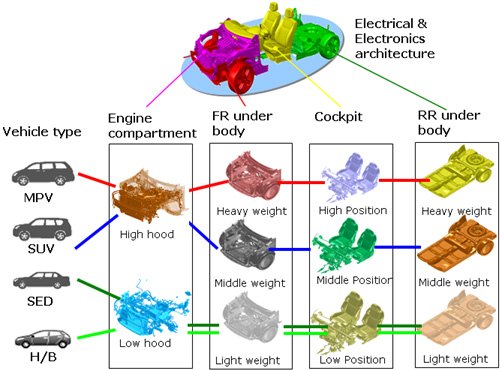

Nissan is somewhere in the middle. Nissan’s CMF uses four modules – engine compartment, cockpit, front underbody and rear underbody and a common architecture for electronic components. They call that 4+1. Then, they change the modules. They will need at least two engines compartments, three front underbodies, three cockpits, and three rear underbodies. Full standardization will take a while.

I pulled a Nissan engineer to the side and asked him how CMF compares to Volkswagen’s MQB. After the requisite quantity of air was sucked through the teeth, my engineer said that Volkswagen is in an enviable position. VW already had been building its cars from a handful of platforms, whereas Nissan “more or less did build a new platform for each car.” So for Nissan, it’s a big step to go to 4+1, which actually is 2x3x3x3+1=55

Indeed, Volkswagen makes its cars from 5 platforms, A0 through D, with most of the volume in A and B. When it comes to standardization, Volkswagen is way ahead of the crowd and can now take the next step towards the holy grail of standard building blocks, “Lego Blocks” as the dream is called in the business.

One indicator of the much higher granularity of the Volkswagen kits: Volkswagen specifically said that the kits allow them to design and built low volume cars quickly and reasonably. Nissan on the other hand stops using the CMF architecture if a car is built less than 5,000 times a year.

Designing cars from common building blocks and making them with standardized parts should lower the cost. Both Volkswagen and Nissan interestingly talk about a 30 percent cost reduction. Don’t think prices will drop because of this. Nissan says that government demands on safety and fuel efficiency raise the cost by 30 percent. The savings from standardization pay for compliance with government rules.

All larger car companies are busy with one standardization project or the other. By the end of last week, Toyota announced that it wants to develop common parts for about half of its 4,000-5,000 components within the next four years. A carmaker that is not thinking about standardization should be thinking about retirement.

The Godzilla of all standardization drives does not seem to happen: Still under the shock of the March 11 earthquake and tsunami, the Japanese government had demanded that automakers standardize most of the parts used by all Japanese makers. As things went back to normal, this demand was quickly ignored and forgotten.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- ToolGuy If these guys opened a hotel outside Cincinnati I would go there to sleep, and to dream.

- ToolGuy Michelin's price increases mean that my relationship with them as a customer is not sustainable. 🙁

- Kwik_Shift_Pro4X I wonder if Fiat would pull off old world Italian charm full of well intentioned stereotypes.

- Chelsea I actually used to work for this guy

- SaulTigh Saw my first Cybertruck last weekend. Looked like a kit car...not an even panel to be seen.

Comments

Join the conversation

So, what will this do for Volkswagen's reliability and repairability? Volkswagen's doing fine in most respects, and I like the looks of their designs -- but I got burned so badly on my 2001 Jetta that I cannot afford to own a Volkswagen vehicle after the warranty expires, and I'm not likely to buy again anyway. Put a 150k-mile warranty on a Jetta Sportwagen TDI or an A4 TDI, though, and we'll talk. Either that, or make it super-easy and super-cheap to replace parts, like the Grumman LLV. I'll take either extreme.

Didn't Steven Lang state that prices have dropped about 30% over a time spanning the 90's to the mid 2000's. Also the Eagle Vision post mentioned how that car was $40,000 plus in todays dollars. I do not think cars are getting more expensive.