Volvo Capacitive Carbon Fiber Panels Could Replace Batteries, Save Weight In EVs & Conventional Cars

That CFRP cowl panel is really storing electricity.

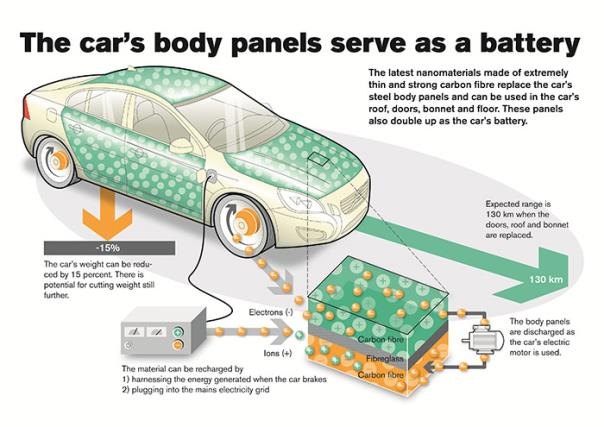

BMW is using carbon fiber composite unibodies for the electric i3 and i8 models to reduce their weight, thereby increasing their range. Now, Volvo is using carbon fiber in a novel way for EVs. Using carbon fiber it has developed a composite material that acts as a capacitor, storing electrical energy, so theoretically body panels and structural components could act as battery equivalents. Unlike conventional batteries, which add weight to a vehicle, the carbon fiber capacitive body panels wouldn’t just power the vehicles but also reduce weight.

To demonstrate the technology, Volvo replaced the the trunk lid, door panels, cowl, and hood of an S80 with the new composite. The panels are made of multiple layers of carbon fiber, insulated from each other with layers of fiberglass. The fiberglass acts as a dielectric with the layers of carbon fiber performing the tasks of the anode and cathode in a conventional capacitor.

Volvo estimates that replacing an EV’s entire battery pack with capacitive panels would reduce total vehicle weight by 15%. It would also help in packaging. One criticism of the Chevy Volt is that its large centrally mounted battery pack turns a five passenger platform into a four passenger car. If the car’s structure is the power source, space formerly used for batteries can be put to better use.

There are possibilities for conventional vehicles as well, with the potential to replace the heavy 12 volt starter battery with just a few capacitive carbon fiber panels.

There are possible drawbacks, including cost and safety. Carbon fiber is expensive to work with so panels would be costly to make and to replace. Also, in the event of a collision that damages the panels’ electrical safety could be a concern.

As usual, there was no world on when, or if, this technology will ever see its way to a production vehicle.

More by TTAC Staff

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- ToolGuy The only way this makes sense to me (still looking) is if it is tied to the realization that they have a capital issue (cash crunch) which is getting in the way of their plans.

- Jeff I do think this is a good thing. Teaching salespeople how to interact with the customer and teaching them some of the features and technical stuff of the vehicles is important.

- MKizzy If Tesla stops maintaining and expanding the Superchargers at current levels, imagine the chaos as more EV owners with high expectations visit crowded and no longer reliable Superchargers.It feels like at this point, Musk is nearly bored enough with Tesla and EVs in general to literally take his ball and going home.

- Incog99 I bought a brand new 4 on the floor 240SX coupe in 1989 in pearl green. I drove it almost 200k miles, put in a killer sound system and never wish I sold it. I graduated to an Infiniti Q45 next and that tank was amazing.

- CanadaCraig As an aside... you are so incredibly vulnerable as you're sitting there WAITING for you EV to charge. It freaks me out.

Comments

Join the conversation

I will try to remember this the next time I pee on an electric car

As to the safety aspect. Carbon fiber is way stronger than steel so it stands a vastly better chance of keeping it's integrity in a collision but... it does not bend, it cracks and shatters and that would not be good. I guess they could use it internally as part of the strengthening framework they use so much now (those super thick A pillars). Exciting stuff anyhoo!