#ProductionCapacity

Audi Approved for $3.3 Billion EV Factory in China

Audi and FAW Group, the state-owned partner it is effectively required to have in order to preferential treatment from the Communist Party of China, received some good news this week. Government officials have approved the duo for a new, jointly operated production facility in Changchun.

With Volkswagen Group having shifted its focus toward China in recent years, the market has become all-important for the German company. VW is currently the top-selling brand for the entire region, with its Audi subsidiary typically being the highest volume premium automaker from Europe. Building in China is good optics for brands hoping to remain popular there and has the added benefit of placing manufacturing complexes closer to relevant suppliers, especially if you’re swapping to electric vehicles.

Renault Reports Staggering $8.6 Billion Loss

Already in the midst of a comprehensive restructuring plan with partners Nissan and Mitsubishi, Renault announced a staggering 7.29 billion euro ($8.6 billion) loss on Thursday. That tally encapsulates the first half of the year and marks a new record for the brand, even if it’s not the kind one normally celebrates.

“Although the situation is unprecedented, it is not final. Together with all of the Group’s management teams and employees, we are fully dedicated to correcting the situation through a strict discipline that will go beyond reducing our fixed costs,” new CEO Luca de Meo said in response to the dismal financial report. “Preparing for the future also means building our development strategy, and we are actively working on this. I have every confidence in the Group’s ability to recover.”

Truth in Numbers: Tesla Motors Kind of Lied to Us

Yesterday, we mentioned how Tesla was behind schedule with its everyman Model 3 — delivering only 220 units to the half-million reservation holders since the start of production in late July. While we knew it would get off to a slow start, CEO Elon Musk previously assured the public that production would increase exponentially through the end of the year by way of a “ production hell” trial by fire.

Musk claimed there should be “zero concern” about Tesla achieving a production rate of 10,000 cars a week before the end of next year. But many wondered if that was even possible. Despite Tesla making serious strides to increase production volume this year, we remained dubious that the proposed numbers were even feasible for a fledgeling automaker.

As it turns out, they weren’t — and the company knew it.

Volvo Doubles South Carolina Investment, Pours In Another $500 Million, Plans Two Production Lines

Volvo continues to look forward to real U.S. sales recovery, meeting the goal of record U.S. sales volume by 2020, and a fourth consecutive year of record global sales. To get there, Volvo is already altering plans at the Charleston, South Carolina, assembly plant where construction is already in full swing.

Altering? According to Reuters and Charleston’s Post and Courier, it’s more like deciding that the plant should be twice as large, build twice as many vehicles, house more than twice as many employees, and cost twice as much.

By 2020, Toyota Wants to Sell Tacoma Pickup Trucks to All Y'all

There are a number of major consequences springboarding off the early August 2017 announcement that Toyota and Mazda would come together to build an assembly plant in Somewhere, United States.

First, Mazda production returns to the United States for the first time since the Mazda 6 left Flat Rock, Michigan, in 2012.

Second, the Toyota Corolla — produced now in Cambridge, Ontario, and Blue Springs, Mississippi — will be assembled in a second U.S. assembly plant.

Third, Toyota will acquire a 5-percent stake in Mazda, while Mazda returns the favor by claiming a 0.25-percent portion of Toyota.

And to the increasingly pickup-truck-conscious U.S. consumer, the most significant consequence of the Toyota-Mazda partnership will be more Toyota Tacomas. That’s right: more pickup trucks for America.

Akerson: Barra Did Not Know About Ignition Defect Before Becoming CEO

Automotive News reports former General Motors CEO Dan Akerson proclaimed in an interview with Forbes magazine that current CEO Mary Barra had no knowledge of the out-of-spec ignition switch that led to the February 2014 recall of 2.6 million vehicles, going as far as to bet his own life on the statement. Barra added the fallout from the recall is a chance for GM to not only “do the right thing and serve the customer well through” the crisis, but “to accelerate cultural change” within the company. Akerson passed the torch to Barra in December 2013 to take time to care for his ailing wife, and has since rejoined Carlyle Group as vice chairman on its board of directors.

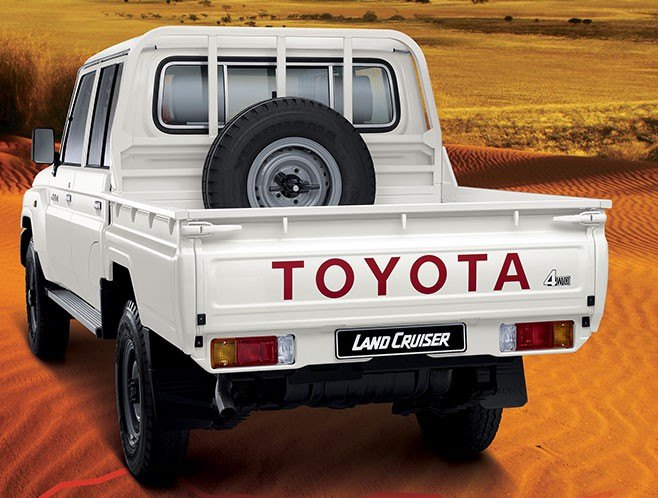

Toyota Looking To Conquer Africa

Though Toyota already has a presence in South Africa, the automaker is eyeing the last untapped market in the world: The African continent.

Honda Pursues 70k Annual US Fit Sales

In 2008, Honda sold nearly 80,000 Fit subcompacts to the United States, and is preparing to move 70,000 annually from the lot to the driveways of America thanks to its new Celaya, Mexico plant.

Recent Comments