#Lockdowns

Report: Honda Considering Seperate Supply Chain for Chinese Market

Honda is reportedly considering tweaking its global supply chain to create a firm distinction between the Chinese and global markets. While the whole world has seen production stymied by restrictive protocols introduced in response to COVID-19, the Chinese Communist Party has retained a zero-tolerance policy that appears to have totally upended its economy and resulted in continued factory stalls. That's bad news for several Japanese automakers that have stepped up their reliance on Chinese production.

Last year, roughly 40 percent of Honda's automotive production (which includes part sourcing) came through China. This year, the company is allegedly wondering how to tear itself away from the market without losing the ability to sell cars to its massive population.

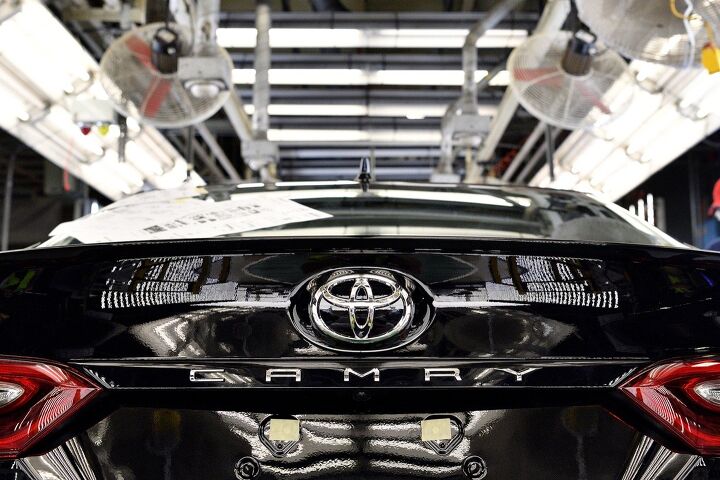

Toyota Scales Back June Production, Ford Drops German Factory

Despite starting 2022 announcing a plan to normalize output, Toyota has had trouble living up to its promise. While most automakers were figuring out how to make more money off diminished production, the Japanese brand was plotting assembly schedules that would restore assembly rates to levels that would have been considered normal prior to 2020. But the rest of the market hasn’t managed to match Toyota’s optimism and the automaker has had to scale back its global production plan yet again — citing the usual supply chain constraints stemming from COVID restrictions and worldwide deficit of semiconductors.

Meanwhile, Ford Motor Co. looks to be abandoning its vehicle assembly plant in Saarlouis, Germany. The facility produces the Focus for Europe and may be in danger of closing if the automaker elects to sell it. While the site was in the running to produce Ford’s next-gen electric vehicles, those products have since been slated for assembly in Valencia, Spain.

How Shanghai Lockdowns Are Changing the Auto Industry

While the semiconductor shortage was long considered the excuse par excellence for why the automotive sector couldn’t produce enough vehicles during the pandemic, some manufacturers have begun pivoting to blaming supply chains that have been stymied by Chinese lockdowns. Toyota is probably the best-known example. But the matter is hardly limited to a singular automaker and market analysts have already been sounding the alarm bell that strict COVID-19 restrictions in Asia will effectively guarantee prolonged industrial hardship around the globe.

Back in April, Shenzhen was emerging from a month-long lockdown. However, the resulting downtime severely diminished the tech hub’s output which exacerbated global component shortages. While Chinese state-run media claimed regional factories maintained full-scale production during the period, the reality was quite a bit different. Meanwhile, Shanghai has remained under harsh restrictions since March and more look to be on the horizon. As an important industrial center and the world’s busiest port by far, the situation has created an intense backlog of container ships that are presumed to create some of the sustained problems that we’re about to explore.

Tesla Pauses Production in Shanghai

Tesla Inc. is briefly suspending production at its Shanghai factory for two days, starting today, as China upgrades restrictions pertaining to a new COVID outbreak. While the rest of the world has been scaling back pandemic-related restrictions, the Chinese Communist Party has begun issuing new mandates after locking down 51 million people at the start of the week. The government has said its part of its no-tolerance approach to the virus after citing roughly 1,700 infections spread across a dozen cities.

This has already started impacting supply chains that have been beleaguered by two years of restrictions already, apparently catching Tesla in the process. Despite Shanghai not having been issued any official orders, there’s been mounting pressure for businesses to temporarily shut down or reinstate protocols to have people work from home.

Salaried Ford Employees to Work Remotely Through June

With so many individuals still working remotely to combat The Dreaded Coronavirus™ from spreading, there have to be thousands of pools on when employees will finally be allowed to return to their cobweb-filled offices. But they have to be getting pretty boring because its hard to imagine anybody confidently putting their money down on late 2021 when this whole thing started in February and the press still thought it wouldn’t be a big deal. The narrative has definitely changed since then and continued social distancing has become a popular solution among businesses, even as state-sanctioned lockdown protocols decline after a few were ruled to be unconstitutional.

On Thursday, Ford decided to keep most of its salaried employees at home until at least June of 2021. That’s eight more months of not going into the office and matches the timetable General Motors issued a few weeks ago.

Michigan Auto Dealers Allowed to Resume Operations Under New Guidelines

Michigan auto dealers will be allowed to resume in-person sales on Tuesday, according to the latest in a long list of executive orders signed by Gov. Gretchen Whitmer. The state, which harbors the fourth-highest coronavirus death toll in the country (following New York, New Jersey, and Massachusetts), has enacted some of the strictest countermeasures in the country.

This has created no shortage of pressure to both reopen Michigan so life/business can return to normal and maintain closures to avoid further contagion risks. Obviously, that’s proven difficult to do. All steps taken towards reopening come with conditions, including those established for Michigan’s dealerships.

But first, some backstory.

Recent Comments