#InsideTheIndustry

Inside The Industry: An Unsung Hero Recalls How A Worldwide Crisis Was Averted

After the March 11 monster earthquake and tsunami wiped out large parts of Japan, headlines focused on the near-meltdown of Fukushima. Recently, I learned that there was a strong likelihood of a worldwide economic meltdown, caused by a microchip factory 80 miles south of Fukushima. Here is the story of how the crisis was contained.

Inside The Industry: TTAC Finds The Missing Etymology Of Passat, Golf, Scirocco, Polo

German launch catalog for the Polo

Where did the names of Volkswagen’s Passat, Golf, Scirocco, Polo come from? What is their meaning? For four decades, it was shrouded in mystery. Forty years later, a famous former Volkswagen CEO, Dr. Carl Hahn, and his illustrious former sales chief, “WP” Schmidt, help TTAC get to the bottom of an unsolved question,

Some of the worst performers in the truth department are the gossip press and the automotive media. A good deal there simply is fantasy. Knowing well that no-one will complain or check, bogus new product plans are being published. The large-scale availability of cheap 3D rendering software ( here is how it’s done) and of WordPress turns this disease into a pandemic.

Most of these lies come and go. Some stay and turn into history. A dark chapter of automotive history falsification is about the names of the new generation of cars that, in the early 1970s, rescued Volkswagen from the brink and that helped turn VW into the powerhouse it is today: Passat, Golf, Scirocco, Polo.

There is so munch nonsense written about those names, that we had to go to the very top, and ask the people who decided these names 40 years ago.

Inside The Industry, Special Edition: The Truth About Getting In

This being Q&A Wednesday, I promised to answer TTAC commenter 28-cars-later’s question in feature-length. He said: “Bertel, how do you get such access to Ghosn… is Nissan just *this* friendly to the press?” Let me explain to you how it works.

Inside The Industry: A Visit At Denza, Daimler's EV Joint Venture With BYD

At the Shanghai Auto Show, which opens to the public on April 21, and to tens of thousands of alleged members of the media the day before, the child of one of the auto industry’s oddest couples will be shown – at least in prototype form. It is the Denza EV, the product of a mésalliance between the world’s oldest and proudest automaker, Daimler, and a company that entered the annals of contemporary automotive history as the most brazen rip-off artist.

Of course we are talking of BYD, the Shenzhen, China, based maker of half the world’s cellphone batteries and a dwindling number of cars. A while ago, I visited an intrepid team of German engineers, shacked up at BYD, to jointly develop an electric car. They were friendly, hospitable, and as forthcoming as possible under the strange circumstances. For months, I could not bring it over me to put my fellow countrymen and expats in the dim light this story would project. Their job is tough enough. But in the interest of timeliness and journalistic duty, here it goes.

Inside The Industry: Busts Of Counterfeit Parts Rings Are Part Of A Much Bigger Sham

The story about fake taxi parts did not surprise me at all. “Police busts fake parts scam” is a fixed part of the standard repertoire of the auto industry theater troupe. That play is longer running than Les Miserables, it definitely made more money than the Phantom of the Opera. The play is a clever sham to separate you from your money, and I helped write the script.

Remember This Top Secret Facility? You Have Been There

After Toyota ended production of the Lexus LFA and closed a chapter of supercar history, National Geographic aired its documentary as part of its Megafactories series. “Up until now, no television cameras have ever been allowed inside this top secret facility,” says the film. The words were carefully chosen. You, the TTAC readers, had been there long before the film went on air.

Inside The Industry: The Making Of A Press Conference – With 45 Exclusive Pictures

At TTAC, we showed you the secrets of how to make a supercar. But what about the real top secrets of a car company, like its earnings? This is insider information, trading on which could make you rich, or poor. It also can land you in jail for a long time. TTAC takes you to the inside of how a car company prepares for an earnings press conference.

Dan Sloan is tired. The head of Nissan’s Global Media Center in Yokohama got up at 6am this morning after days of not much sleep. Today is the day when Nissan’s third quarter earnings are to be announced to the press, and the world at large. It will be a long day of preparations for the big announcement in the late afternoon, and TTAC will be the fly on the wall. Or, as Sloan predicted, the fly in the ointment.

The Making Of The Lexus LFA Supercar: An Inside Report, Chapter 5: Exam Week.

On the LFA’s in-house test track. Each car gets tested for some 50 miles

In this week-long report, we followed the Lexus LFA from raw fiber to body, paint, and assembly. In this final chapter, we take it on the test track in Motomachi.

Each and every LFA that rolls off the line is checked like no other car. 7,000 items of the LFA, all previously checked, counter-signed, eternalized in evidence sheets, are checked again. Each check again is eternalized in evidence sheets. When I said it takes 8 days to make an LFA, I lied. It takes 8 days to make one, and then it takes a full additional week to check it.

The Making Of The Lexus LFA Supercar. An Inside Report, Chapter 4: Balance Of Power

In the preceding chapters, we followed the Lexus LFA from raw fiber to body, paint, and assembly. Today, the LFA gets its engine. Tomorrow, we’ll test it, and then, we’ll say good-bye to the LFA Workshop in Motomachi.

On its slow road to completion, the LFA travels down a main line, where it is met by components that come from smaller sidelines. One such subassembly is the LFA’s V10 engine. Covered by a thick sheet of plastic, it comes from Yamaha where it was built and assembled. The engine was a balancing act, in more ways than one.

The Making Of The Lexus LFA Supercar. An Inside Report, Chapter 3: Call Me Names

LFA carbon fiber body

After a general introduction in the first chapter, the last chapter of this inside report showed us how the body-in-white of the LFA is hand-made layer by layer, and that it is actually a body-in-black. When finished, the body goes on a transfer cart and travels one third of a mile to the second stage of the LFA production, painting and final assembly. We take a bus.

The Making Of The Lexus LFA Supercar. An Inside Report, Chapter 2: In The Clean Room.

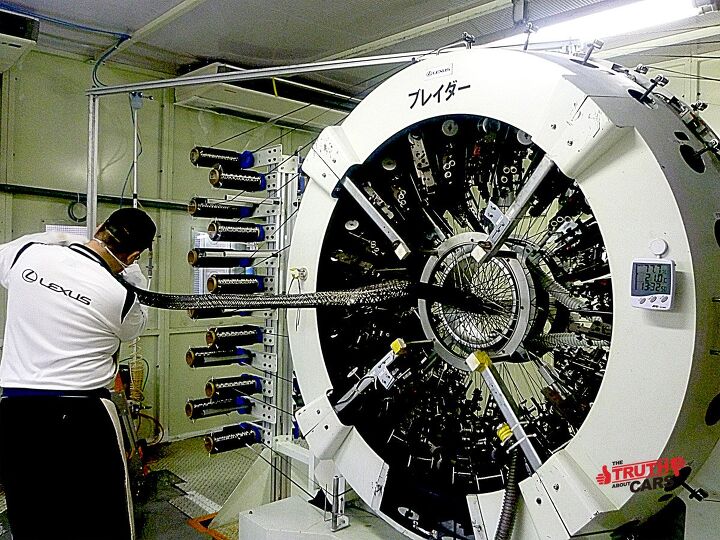

One of two circular looms on the planet. 12 layers of seamless carbon fiber are woven into what will be part T3-3RH, part A-pillar, part roof support

Yesterday, we heard how the LFA really was born (in a bar, where many good ideas are born and pitched,) and why it is made from carbon fiber. Now, we are in front of the cleanroom, and while our little group is suiting up, let’s use the time for a quick course on CFRP.

The basic principle of Carbon Fiber Reinforced Polymer, CFRP for short, is not new. It dates farther back than metal. CFRP is a composite, made from two completely different materials that are joined together to give a much stronger material. Straw and clay was such an early composite. Concrete is a more recent one. In the case of CFRP, carbon fibers are combined with epoxy, the polymer. Sometimes, the material is also called “carbon fiber reinforced plastic,” but the end product is far removed from what usually comes to mind when we think of plastic.

The Making Of The Lexus LFA Supercar: Who, What, Where And Most Of All Why. An Inside The Industry Report, Chapter 1: From A Bar To Bar None

The autoclave. A giant pressure cooker that limits the Lexus LFA production to one per day

Behind a nondescript garage door in the Motomachi plant in Toyota City is LFA Kobo, the LFA Works. Here, 170 men and women chase the holy grail of car making. Their mission: How to make a car super fast, super light, super safe, and affordable. They have mastered the first three. On the affordable they are still working. The holy grail is being chased in a supercar, the $375,000 Lexus LFA.

One Year After The Disaster, A Visit To A Symbol Of The Recovery: Toyota's Prius C Plant

Today, at 2:46 pm, Japan came to a stand-still, again. Trains and subways stopped. People did fold their hands, faced in the general direction of the northeastern coast of Tohoku, and said a silent prayer. Japan and the world marked the one year anniversary of the earthquake and tsunami that left whole towns razed, more than 19,000 people dead or missing, 344,000 people displaced, and a large area around the destroyed Fukushima Daiichi power plant off-limits for decades, if not permanently.

Writers often like to equate the power released by the quake to the nuclear bombs that had been dropped on Hiroshima and Nagasaki. Depending on who you read and believe, it was anywhere between 31,700 and 600 million Hiroshima bombs. Large parts of the coastal areas are dotted with huge, neatly stacked piles of rubble which nobody wants to take and nobody knows what to do with. The devastation was so big that it turned into an attraction on Google Earth. Considering the immense damage, it is amazing how quickly the country did rebound. On Friday, I visited what was presented to me as an emblem of the amazing turn-around, Toyota’s plant in Kanegasaki, Iwate Prefecture. Here, 1,700 employees are working overtime to build Toyota’s Aqua / Prius c, for which everybody is screaming.

Toyota's Secret Weapon: Low Cost Car Factories

Today, I saw a new, and so far the finest specimen of Japan’s new export products: A car factory. Remember when the Nikkei wrote about a new Toyota factory in the Miyagi Prefecture with a U-shaped assembly line where the assembly time is cut down to a third? Not only did they get it wrong. They missed the best part of the story: Budget car factories, ready for export. Of course, that’s not how it was sold to the natives.

Ohira is a little village near Sendai. Sendai is a town two Shinkansen hours north of Tokyo. The area is famous for its beef tongue, not the hottest export item. Ohira was known for exactly nothing until Toyota decided in 2007 to relocate their factory from Sagamihara, in the outskirts of Tokyo, up into the woods of Ohira.

A year later, the whole region went into shock:

Recent Comments