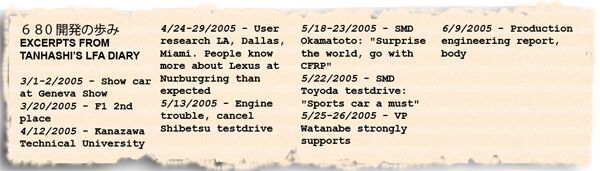

The Making Of The Lexus LFA Supercar. An Inside Report, Chapter 3: Call Me Names

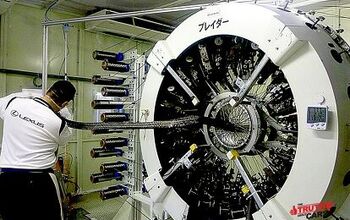

LFA carbon fiber body

After a general introduction in the first chapter, the last chapter of this inside report showed us how the body-in-white of the LFA is hand-made layer by layer, and that it is actually a body-in-black. When finished, the body goes on a transfer cart and travels one third of a mile to the second stage of the LFA production, painting and final assembly. We take a bus.

Tanahashi and entourage on their way to the assembly hall

In the bus, we talk about the name of the LFA. There are all kinds of apocryphal stories of how the name came about and what it stands for, that it means “Lexus Future Advance”, or whatever. Tanahashi say it is all nonsense, and as I listen to him talk, I know that I am finally hearing the true story.

Bodysnatcher

“Like all cars, the LFA started as an internal project, code 680,” Tanahashi says. Now you know what the 680 means in Tanahashi’s diary.

“At the Detroit Motor Show 2005, we showed a concept. We needed a name. At Lexus, concept cars for the motor show follow a strict name regime. LF for ‘Lexus future’, then a dash, followed by two letters. I racked my brain for a good two letter combination. I could not find one, and settled on A.”

The concept was shown as LF-A. Four years later, Tanahashi gave the name equally short shrift:

“In 2009, we announced the car at the Tokyo motor show, and we needed a real name. Again, I had a hard time. I thought, why not simply remove the hyphen? The LFA was born.”

Many decisions in the car industry happen that way. Rich and deep symbolism often is an after-the-fact addition born from an insatiable quest for meaning.

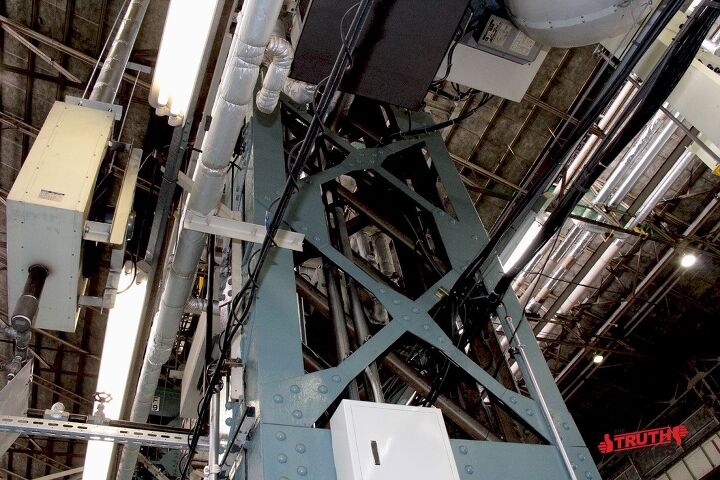

New meets old

The titanium muffler.

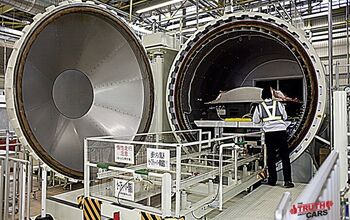

We are back at the LFA’s assembly building. Painting and assembly is a place where Toyota’s past meets Toyota’s future. This was an old press shop before the LFA moved in. The trusses and riveted girders of this 10,000 sqm hall remind more of the Brooklyn Bridge than of a breeding ground for yet to come car architectures. A large overhead crane, now retired, could, if reactivated, travel the full length of the hall. During the LFA’s prototype phase, birds had entered the building and left their signatures on cars and workers. Now, piano wires invite the birds to sit elsewhere.

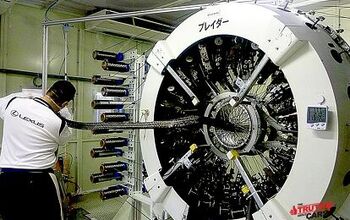

A quarter of the hall is walled-off to house the LFA’s paint and assembly shop. Most of the LFA’s body, 65 percent to be exact, is made out of carbon fiber reinforced polymer, or CFRP, the remainder is made out of aluminum. Attempting to apply my newfound knowledge, I point at a shiny metal object, and am told that it is a muffler.

Titanium muffler

“It is made from titanium,” says Tanahashi.

The SR-71 Blackbird spy plane ($ 33 million MSRP) was made largely from titanium, the LFA uses the metal for a muffler. Titanium has the highest strength-to-weight ratio of any metals. Titanium is strong as steel, at approximately half the weight. The only heavy part of titanium is its heavy price: Titanium costs approximately 20 times as much as steel. To replace that muffler – not that you would ever have to, titanium is extremely corrosion resistant – would cost the price of a Corolla, I am told.

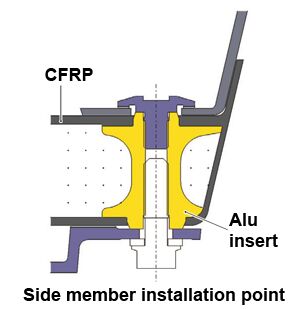

When the bonded body-in-black rolls into the assembly hall, it already has fasteners in place to which other parts are mounted. Lighter parts, such as wire harnesses, are attached with fasteners that are bonded to the surface of the CFRP body.

While we are discussing fasteners, Tanahashi brings a cutaway piece of foam-cored carbon fiber. What he shows is testament to the compulsive attention to the minutest detail. In the LFA, through-fasteners don’t simply go through holes that are cut into the shell. They use special aluminum inserts that prevent the carbon fiber from being weakened by the pressure of a lug nut, or the chafing of a thread.

Fender being fitted to the non-monocoque LFA

“Definitely not a monocoque.”

At this point, a discussion ensues. I call the body of the LFA a monocoque, because this is what everybody seems to call it. Tanahashi and Tamura disagree. In a monocoque, the external skin supports the load of an object, I am told. An egg is a monocoque. The hen is not. In the LFA, the car’s structure is delivered by a rigid center cell with attached front and rear subframes. To that, removable body panels are applied, and I watch how they do it.

These panels act like a skin, for internal protection and outward beauty, but not for bearing the LFA’s load. When we discuss the architecture, Chief Engineer Tanahashi declares with deep conviction and utmost finality that this is “definitely not a monocoque.”

Panels being fitted to the non-monocoque LFA

Asked what it is, Tanahashi describes it as a “body-kokkaku” which can loosely be translated as “body frame structure.” After a long discussion, we come to the conclusion that “space frame” probably comes closest, but not close enough for a tough Tanahashi, who thinks it is an old-fashioned term, “suitable for the birdcage of, say, a Maserati Tipo 61.” Once again, the LFA defies definition.

Japanese laquerware.

Painting takes place in another cleanroom. The body panels are first wet-sanded and sealed with a gelcoat. Next comes a middle coat in one of four colors, depending on the final color. Then comes the top coat in the requested color, and finally, a clear coat. The layers are dried at 90 C for 20 minutes. Every coat is inspected under special bright lights.

Check of the paint

The LFA can be had in 30 colors. Strangely, the simplest ones, matte black and whitest white are the most difficult. Matte black cannot be polished and is tricky to handle. The paint specialists are glad that this much talked-about color is in low demand. Only 12 out of 500 LFA have been ordered in matte black.

Still checking

The by far most popular color is whitest white. Its base coat is covered with a layer that shines in blue and white under fluorescent light, on top of that comes an enamel coat that in turn is covered by a clear coat. “Regular” pearl white is the second-most requested color, followed by regular black and red.

Whitest white is highly popular with the paint booth staff also. That color is so complex, “it creates overtime,” says Tanahashi.

It’s a roof side rail garnish. (We asked.)

The Natural.

Assembly of the LFA takes four days, the second half of the supercar’s eight day metamorphosis from space-age twine to blissful bolide. In those four days, the car crawls down a slow, but deliberate assembly line. It is manual work, but it is the manual work of a symphony orchestra. Each grip, each part, each turn of a wrench has its set time and purpose. The orchestra has its sheet music: Placards at every station list what needs to be done when. One can feel the rhythm, even hear the distinct melody of the line.

The coach

The LFA’s 170 piece orchestra of course has its conductor. His name is Shigeru Yamanaka, and he cuts an imposing figure. Before he managed the LFA Works, Yamanaka was the coach of Toyota’s corporate baseball team.

Yamanaka will disappoint you if you are fishing for a story of him selecting only the very best and most highly skilled workers that are run through some astronaut-type selection process.

Instead, Yamanaka surprises us with refreshing honesty.

100% dedication

Asked how he picks his team members, Yamanaka replies: “I request them from Human Resources.”

“I look for passion,” says Yamanaka. “I look for people who want to make special things. Skills I can train. Enthusiasm you are born with.”

Indeed, I see only two types of facial expressions as I walk down the line: Smiling faces. Or deeply concentrated ones. The LFA is made 65 percent from CFRP, 35 percent from aluminum alloy, and 100 percent from dedication.

Assembly hall

PS: With all the innuendo and supposition about the Tiffany blue LFA, how could anyone miss the fact that the original project code was 680, the same number 680 that was on the license plate of the blue LFA?

It’s good they did. “It was one of those coincidences,” I am told.

Stay tuned for tomorrow’s installment of The Making Of The Lexus LFA. How long do you think this car will last?

Monday, July 9: From A Bar To Bar None. How the LFA was born, and why it is made from carbon fiber.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- MaintenanceCosts Whenever the topic of the xB comes up…Me: "The style is fun. The combination of the box shape and the aggressive detailing is very JDM."Wife: "Those are ghetto."Me: "They're smaller than a Corolla outside and have the space of a RAV4 inside."Wife: "Those are ghetto."Me: "They're kind of fun to drive with a stick."Wife: "Those are ghetto."It's one of a few cars (including its fellow box, the Ford Flex) on which we will just never see eye to eye.

- Oberkanone The alternative is a more expensive SUV. Yes, it will be missed.

- Ajla I did like this one.

- Zerofoo No, I won't miss this Chevrolet Malibu. It's a completely forgettable car. Who in their right mind would choose this over a V8 powered charger at the rental counter? Even the V6 charger is a far better drive.

- Offbeat Oddity Nope, I won't miss it. I loved the 2008-2012 Malibu, but the subsequent generations couldn't hold a candle to it. I think the Impala was much more compelling at the end.

Comments

Join the conversation

Sorry. I`d rather tour the Ferrari plant.

and hype their product.....