The Making Of The Lexus LFA Supercar. An Inside Report, Chapter 4: Balance Of Power

In the preceding chapters, we followed the Lexus LFA from raw fiber to body, paint, and assembly. Today, the LFA gets its engine. Tomorrow, we’ll test it, and then, we’ll say good-bye to the LFA Workshop in Motomachi.

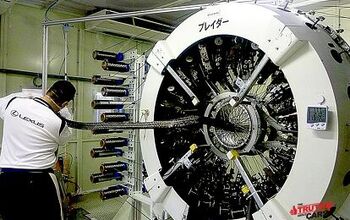

On its slow road to completion, the LFA travels down a main line, where it is met by components that come from smaller sidelines. One such subassembly is the LFA’s V10 engine. Covered by a thick sheet of plastic, it comes from Yamaha where it was built and assembled. The engine was a balancing act, in more ways than one.

Slowly, the LFA nears final completion

The engine sits behind the front wheels. The transmission, or rather transaxle, sits in the rear, balancing out to an ideal 48:52 front/rear weight distribution. Engine and transaxle are connected by a torque tube for a balance of lightness and durability.

The engine arrives pre-assembled from Yamaha

Through generous use of aluminum, titanium, magnesium and brain matter, the LFA’s engine is light. How light? I am unsuccessful in prying the engine’s weight out of the otherwise very forthcoming engineers. It will remain a secret until someone weighs the thing.

Mating ritual

“It makes no sense to save all that weight with composites, only to waste it on a heavy engine,” says Tanahashi. The LFA’s V10 is as small as a traditional V8, it is as light as a conventional V6, and yet delivers the power of a V12. The engine is light, but at 560 hp and 480 Nm (354 lb ft) of torque it certainly is no lightweight.

Here comes the power

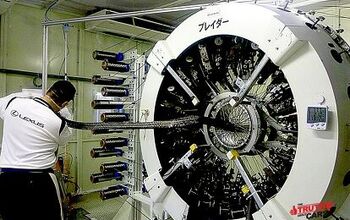

The torque band of some engines is so peaky that it can do double duty as a Jayne Mansfield look-alike. Dyno the LFA, and it will draw a diagram as flat as a Japanese beauty: 90 percent of the LFA’s peak torque is available from 3,700 rpm all the way to the rev limiter. In this case, flat definitely is the sexier choice.

Chain of custody.

Speaking of the dyno, every LFA goes on one, not just to check the engine or the brakes, but even for such prosaic exercises as checking the accuracy of the speedometer.

How much torque?

One instrument appears to be banned from the LFA’s philharmonic symphony. There is no staccato sound of the pneumatic torque wrench. It would be too imprecise, I hear. Instead, each bolt is torqued with a digital, however manual torque wrench. After each bolt, the worker stops and makes notation on a sheet.

Mountain of evidence

To my bafflement, I learn that the torque for every bolt in the LFA is recorded on what is called an “evidence sheet.” Not just the torque of every bolt. Everything that is touched, assembled, hand-laid, bonded, adjusted, or checked in each and every LFA made receives an entry in an evidence sheet. The sheet is signed by the person that enters the data, and then it is signed again by a foreman.

50 years from now, the evidence will still be there: Miyoshi and Tanahashi are checking the files

Whenever one of the each of the 500 LFAs leaves Motomachi, administrator Mami Murofushi puts four heavy file boxes, filled with a collection of thousands of evidence sheets, on a shelf in an archive room a few steps away from the LFA Works. Aligned by build number, the file boxes will sit there at least for the next 50 years.

FRP is forever.

Why will the evidence be kept for more than 50 years? For one thing, because the LFA likely will last longer than that. Honestly, Tanahashi does not know how long the LFA will last.

“I feel the material could live permanently,” says Tanahashi. “To be safe, let’s say semi-permanently.” Looking at a semi-eternal service life, Tanahashi is not worried about end of life issues. Some people are. They paint a picture of rust-resistant carbon fiber bodies that will pile up on landfills half a century after they can be made in an affordable way. Tanahashi has thought of that as well and says that if and when the time comes, the carbon fiber LFA can be “crushed and the material can be used for building reinforcement.”

A week’s work, lined up for inspection

7:14.64

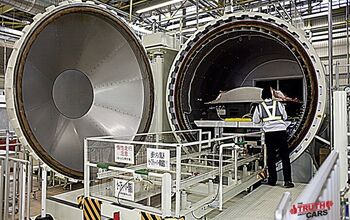

With that in mind, we travel to another hall at the northeastern end of the Motomachi complex. This is where cars receive a very intrusive physical before they get delivered. A full week’s worth of LFA production, all seven of them, are lined up for inspection.

One of the LFAs awaiting a physical is a Nürburgring Package version. The package is a $70,000 extra, and only 50 are being sold. I would not have noticed it, would Tanahashi not have pointed it out. It is the white one on the right.

Insert $70,000 right here

Those $70,000 buy you 11 additional horses. “That is the main difference,” says Tanahashi. The suspension has a different adjustment. There are little winglets on the side, and “slight changes inside of the engine room,” I hear.

Asked what those changes are, Tanahashi grins, he pops the hood and shows a silver oil filter, and a red-on black plaque that says “Handbuilt by Lexus LFA Works” instead of the regulation champagne-colored oil filter and plaque. If I had to ask …

Oil filter, special Nurburgring edition

“It is expensive, but it shaved 8 seconds off our Nürburgring lap time,” says Tanahashi, referring to the 7:14.64 Nordschleife lap time achieved on August 31, 2011.

Ignoring the lap times of three cars of dubious provenance, the LFA on regulation Bridgestone tires was the fastest production, street-legal car around the ring. For two weeks, it was. On September 14, a Dodge Viper ACR on Michelin Pilot Cup slicks came in two and a half seconds faster, and this is where things stand ever since.

I ask Tanahashi whether he will try again. He does not answer, and looks the other way.

Stay tuned for the final installment of The Making Of The Lexus LFA:

Monday, July 9: From A Bar To Bar None. How the LFA was born, and why it is made from carbon fiber.

Slowly, the LFA nears final completion

The engine arrives pre-assembled from Yamaha

Mating ritual

Here comes the power

How much torque?

Mountain of evidence

50 years from now, the evidence will still be there

A week’s work

Insert $70,000 right here

Oilcooler, special Nurburgring edition

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Tassos Tim is not that good with colors.The bright "pink" is not pink, but FUCHSIA. Both colors may look good on a woman's sweater, but not on steel panels.

- Tassos While I was a very satisfied owner of a much earlier Accord COupe 5 speed (a 1990 I owned from 1994 to 2016), I don't like the exterior styling of this one so much, in fact the 2017 sedan looks better. Or maybe it sucks in white. The interior of my 1990 was very high quality, this one looks so-so. The 157 k miles were probably easy highway miles. Still, Hondas are not Toyotas, and I remember the same service (like timing belt replacement) back then cost TWICE for an Accord than for a Camry. Add to this that it has the accursed CVT, and it's a no. Not that I am in the market for a cheap econobox anyway.

- 3-On-The-Tree My 2009 C6 corvette in black looks great when it’s all washed and waxed but after driving down my 1.3 mile long dirt road it’s a dust magnet. I like white because dust doesn’t how up easily. Both my current 2021 Tundra and previous 2014 Ford F-150 3.5L Ecobomb are white

- Bd2 Would be sweet on a Telluride.

- Luke42 When will they release a Gladiator 4xe?I don’t care what color it is, but I do care about being able to plug it in.

Comments

Join the conversation

I wonder why they won't disclose the weight of the engine. 1) They don't know. They never measured it. 2) Disclosing the weight would expose secrets about the construction and materials that are commercially sensititive and competitors could reverse engineer the whole thing if they just knew the weight. 3) They are giving a free iPAD to anyone who can correctly guess the weight. 4) They're too embarassed to tell you

Building an LFA comes down to one word: Craftsmanship BD