Detroit Wrapping on Ventilator Production, Returning to Cars

General Motors and Ford Motor Company are about to conclude their prolonged stint of ventilator production. In case you were unaware, these businesses typically manufacturer automobiles (cars, for the layperson) and have allocated a portion of their factory space to build medical equipment that was assumed to be useful during the pandemic. However, the United States now has more ventilators than it knows what to do with, and most of them seem like they won’t be required — so it’s mission accomplished, unless COVID-19 suddenly becomes a much more vicious illness.

Either way, GM and Ford both plan to re-prioritize vehicle production. The Blue Oval moved core staff off ventilator lines and back to their normal places of assembly months ago. Some of the remaining temporary workers hired to assist with the medical equipment are said to have an opportunity building the new Ford Bronco. Meanwhile, GM says it wants to move ventilator production to a facility in Kokomo, Indiana, next month, where it will hand operations over to Ventec Life Systems as it regains the union employs allocated for the project. Temporary hires will be absorbed by Ventec.

According to Reuters, GM and Ventec are in the last leg of completing their joint contract to deliver 30,000 critical care ventilators by the end of August under a $489 million contract with the federal government. Ford has reportedly assembled around 47,000 of the 50,000 ventilators it agreed to supply with help from General Electric Co. That contract is worth roughly $336 million.

From Reuters:

[Health and Human Services] said it has received more than 69,000 ventilators assembled by GM, Ford and their partners, and “both of these delivery schedules are nearly complete.”

Ford and GM earlier this year said they would employ a total of as many as 1,500 people on ventilator assembly lines. Automakers likened the efforts to their switch from making cars to tanks and planes during the Second World War.

While roughly 12,000-15,000 ventilators have been issued to U.S. hospitals, the Health and Human Services (HHS) department reported that the government has nearly 110,000 ventilators stockpiled. While President Trump suggested a large portion of those will be issued to other countries in need, demand has come down immensely. We know the United States shipped heaps of personal protective equipment to China before COVID-19 officially became a global pandemic, and that the plan was to continue doing so while incorporating breathing machines (though the latter would not be donated) once the U.S. had a reliable supply for itself. It was also made clear that other nations would be given priority, as Trump said he planned to donate 200 to the United Kingdom in April.

But treatment strategies changed.

Invasive ventilators have been replaced with sleep apnea machines for at-risk patients or simply rolling them onto their sides and giving them helpful prescriptions. The HHS also confessed that the U.S. probably never needed quite so many units as were being manufactured. “States initially requested far more ventilators than they actually needed,” an HHS spokeswoman explained, adding that orders were placed at at time where the nation had more questions than answers.

Even though ventilators are being taken off the table at automotive plants, the industry will still manufacture personal protective equipment (masks, face shields) for the foreseeable future. Demand for PPE has not diminished in the slightest, and the situation is unlikely to change while face coverings are still required to interact with the public. It’s a situation we don’t see changing, even as Sweden ( a country that went largely mask-free, didn’t do lockdowns, and still avoided mass contagion) has started to claim that masks are effectively useless against the virus. The rhetoric is quite different here, though not terribly distinct from most first-world nations that wanted to exercise the maximum amount of caution.

Presidential candidate Joe Biden recently said that “ every governor should mandate mandatory mask wearing” and recommended their continued use until at least November of this year. The right has been more flippant about the usefulness of face coverings in general, but even President Trump offered his own tepid endorsement this summer.

We figure this will result in automakers tossing together masks until at least 2021, though the demand this places on companies is much lower than ventilator manufacturing and shouldn’t interfere with the core business of building cars.

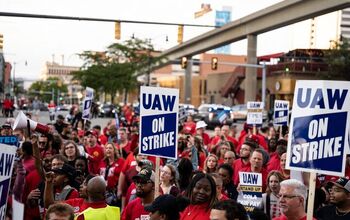

[Image: John Gress Media Inc/Shutterstock]

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Kjhkjlhkjhkljh kljhjkhjklhkjh A prelude is a bad idea. There is already Acura with all the weird sport trims. This will not make back it's R&D money.

- Analoggrotto I don't see a red car here, how blazing stupid are you people?

- Redapple2 Love the wheels

- Redapple2 Good luck to them. They used to make great cars. 510. 240Z, Sentra SE-R. Maxima. Frontier.

- Joe65688619 Under Ghosn they went through the same short-term bottom-line thinking that GM did in the 80s/90s, and they have not recovered say, to their heyday in the 50s and 60s in terms of market share and innovation. Poor design decisions (a CVT in their front-wheel drive "4-Door Sports Car", model overlap in a poorly performing segment (they never needed the Altima AND the Maxima...what they needed was one vehicle with different drivetrain, including hybrid, to compete with the Accord/Camry, and decontenting their vehicles: My 2012 QX56 (I know, not a Nissan, but the same holds for the Armada) had power rear windows in the cargo area that could vent, a glass hatch on the back door that could be opened separate from the whole liftgate (in such a tall vehicle, kinda essential if you have it in a garage and want to load the trunk without having to open the garage door to make room for the lift gate), a nice driver's side folding armrest, and a few other quality-of-life details absent from my 2018 QX80. In a competitive market this attention to detai is can be the differentiator that sell cars. Now they are caught in the middle of the market, competing more with Hyundai and Kia and selling discounted vehicles near the same price points, but losing money on them. They invested also invested a lot in niche platforms. The Leaf was one of the first full EVs, but never really evolved. They misjudged the market - luxury EVs are selling, small budget models not so much. Variable compression engines offering little in terms of real-world power or tech, let a lot of complexity that is leading to higher failure rates. Aside from the Z and GT-R (low volume models), not much forced induction (whether your a fan or not, look at what Honda did with the CR-V and Acura RDX - same chassis, slap a turbo on it, make it nicer inside, and now you can sell it as a semi-premium brand with higher markup). That said, I do believe they retain the technical and engineering capability to do far better. About time management realized they need to make smarter investments and understand their markets better.

Comments

Join the conversation

Another example of why it is so important for a nation to maintain manufacturing capabilities. And in particular auto manufacturing. Germany, Japan, Italy and France (all nations that surrendered during WWII) realize this and maintain strict government intervention/interference to retain a domestic auto industry. The USA which was the arsenal of democracy utilized its auto industry to overwhelm the Axis powers by manufacturing a multitude of aircraft, tanks, trucks and assorted other weapons of war. In times of crisis a nation often needs to depend on its own internal capabilities.

@don1967 - If one factors health care costs like insurance into the equation, Canadians are on par with the USA for cost of living. Canada scores much higher on other indices. Trade unions aren't a destabilizing force unless they get too strong which rarely happens. What is more important than cutting regulations and dropping taxes is to have a stable "level" playing field. "Strict government action" as you put it isn't necessarily required unless you are dealing with countries like China. Countries with similar economic, social, and politically democratic standing don't tend to need government intervention in business or trade.