Owner of Tesla With Cracked A-pillar Gets Action, But No Answers

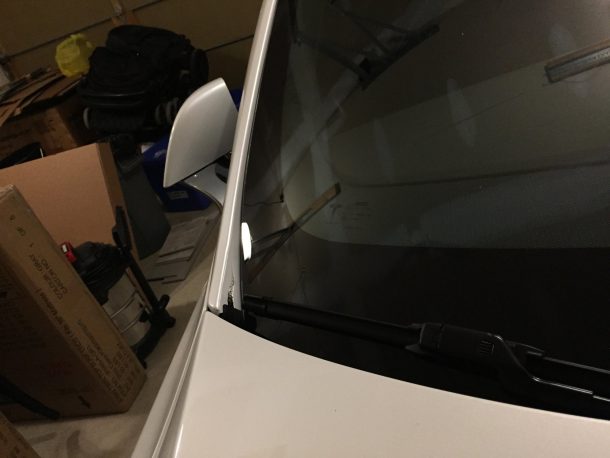

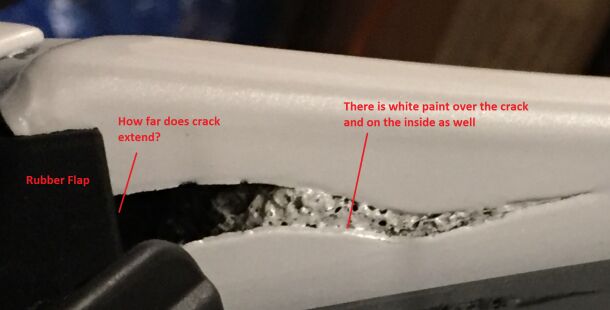

Earlier this month, we detailed the plight of a Toronto-area man whose newly delivered Tesla Model S 90D — a six-figure vehicle boasting cutting-edge technology — arrived from the factory with a sizable crack in the A-pillar.

Because the A-pillar forms part of a one-piece aluminum side member, the defect represented a structural fault that couldn’t be ignored. It wasn’t the kind of PR Tesla wanted, especially as it ramps up production (and stock value) ahead of the Model 3 launch, and it certainly wasn’t something a first-time owner and admitted Tesla fan wanted to find.

After airing his story on the Tesla Motors Club forum, the owner provided TTAC with updates on his vehicle’s status.

The owner, who goes by the name Snowstorm on the forum, acted quickly after finding the Red Sea-like crack. Though he ran into some attitude from his delivery specialist early on, the crack was obviously a manufacturing-related imperfection, not a fault of the new owner. So, after a some back-and-forth with his local Tesla service center, it was off to the certified body shop for his Model S.

And, in the body shop it remains.

“Right now, the car is at the local certified body shop,” the owner wrote on April 9th. “They just completed their evaluation and sent his assessment to Tesla engineering to determine how to fix this. The manager says if it is up to him, he’ll repair it rather than replace, as a replacement will be very invasive.”

That potential remedy rubbed the owner the wrong way, as he doubted the side member was capable of actually being repaired. After telling the service manager he’d like to have a new car built, he was told to wait to hear his options.

The next day, the owner received his wish.

“Dustin, the regional service manager here contacted me and said they’ll rebuild my car,” he wrote. “I don’t know how the logistics will work out due to the lease, [and] government rebate applications. The price and options are also different now for the Model S.”

At this point, the owner claimed he felt confident in the process, adding the Tesla team has been very accommodating. He returned to the online vehicle configuration page to help rebuild the new Model S, as there were options he neglected to check off the first time around.

Yesterday, more news from our Torontonian Tesla owner:

I’ve just send in my request for a re-build yesterday to Dustin who is now working with his team to figure out the logistics of how Tesla will take my vehicle back, build a new one and transfer the lease. I was planning to add the rear facing seats since I now have an extra child. The pricing structure has changed quite a bit since I last ordered mine 6 months ago and just changed again, so I am in uncharted territories on that now.

Eventually, an uncracked Model S will return to the owner’s driveway. Still, he wonders about what caused such a significant crack in the A-pillar, and how it passed under the noses of quality control inspectors at Tesla’s Fremont, California factory undetected. So far, no answers.

(We fielded several emails from auto industry employees who pointed to the stamping process as the logical source of the defect, but that’s up to Tesla to confirm.)

“My original car is still in the Toronto area body shop according to my app, but Dustin said they’ll be shipping it back to the factory for examination,” the owner wrote. “Hopefully, the original build process is well recorded so they can see what/who missed this and prevent this from reoccurring.”

If the owner hears anything from Tesla on that front, we’ll dutifully pass the information along.

[Image: Tesla Motors Club Forum]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Spectator Wild to me the US sent like $100B overseas for other peoples wars while we clammer over .1% of that money being used to promote EVs in our country.

- Spectator got a pic of that 27 inch screen? That sounds massive!

- MaintenanceCosts "And with ANY car, always budget for maintenance."The question is whether you have to budget a thousand bucks (or euro) a year, or a quarter of your income.

- FreedMike The NASCAR race was a dandy. That finish…

- EBFlex It’s ironic that the typical low IQ big government simps are all over this yet we’re completely silent when oil companies took massive losses during Covid. Funny how that’s fine but profits aren’t. These people have no idea how business works.

Comments

Join the conversation

With a pay scale of $17 to $21 per hr., you might have a workforce that is closer to the Chevy truck plant in terms of motivation. That and worker complaints about the lack of mechanical lifting and assembly assist machinery, common in other plants, leaves me wondering about the professionalism of Elon Musk's management team. http://www.mercurynews.com/2017/02/09/tesla-worker-long-hours-low-pay-and-unsafe-conditions/

My mistake. The article refers specifically to long hours, low pay - especially for a job in the Bay area, and unsafe working conditions. Also all workers are required to sign an overly broad non-disclosure agreement on hiring. The big picture here indicates that management isn't using the Toyota system as a model, at least for quality control. This is, at least, ironic, but it appears that they are improvising as they go, and the workers are picking up the slack. http://prospect.org/article/tesla-workers-file-charges-national-labor-board-battle-elon-musk-intensifies