972 Views

BMW Partnering With Kymco For I3 Range Extender

by

Derek Kreindler

(IC: employee)

Published: March 19th, 2013

Share

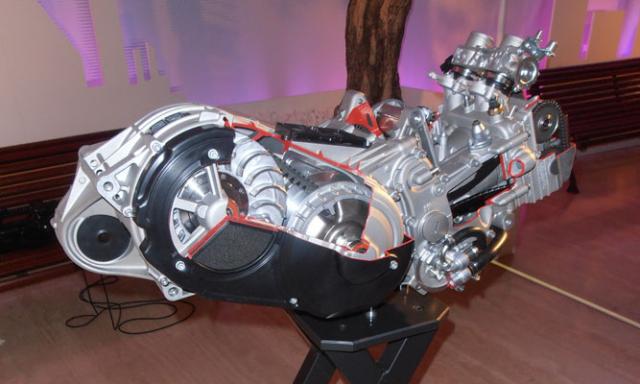

The gasoline range-extender that will be optional in BMW’s i3 electric car will be built by Kymco, a Taiwanese firm that is best known for its scooters.

BMW and Kymco have worked together in the past, with Kymco building engines for the BMW G450X dirt bike. The two-cylinder motor was designed in Germany but built by Kymco’s Taiwan factory – and the i3 will likely have a similar arrangement, given the familiarity between the firms. The parallel-twin will apparently be given extensively changes for the i3, especially given that the requirements for a motorcycle engine and a range extender being run at a constant load are very different.

Derek Kreindler

More by Derek Kreindler

Published March 19th, 2013 1:58 PM

Comments

Join the conversation

Volvo had a Turbine/electric concept car in the 1990s called the ECC. Introduced with great fanfare in the buff books, it vanished with nary a whimper. It would be nice to find out what Volvo learned from its experience.

This is a good idea, since it will be a more optimal package than a standard ICE transplant (like the Volt).

Oh I can see it in the near future. Some preening hipster exclaiming in the Whole Foods parking lot: "It's a BMW and Electric; it's just so green and eco-friendly!!! Nevermind the range extender was built in Taiwan and shipped to Germany and then the whole car was shipped from Germany to the US. Yeah, that's green.

If one would listen to the "laundry list" of how environmentally "unfriendly" EV's are, one would think twice about buying one. Which is exactly what Big Oil wants. There are people (admittedly, well-off) who own EV's and have solar/wind power at home who can literally drive for free (once the initial investment is out of the way). Yes, they're a very small minority, but it just proves that IF WE REALLY WANTED TO, we could do most of our personal driving with NO OIL. It's feasible.