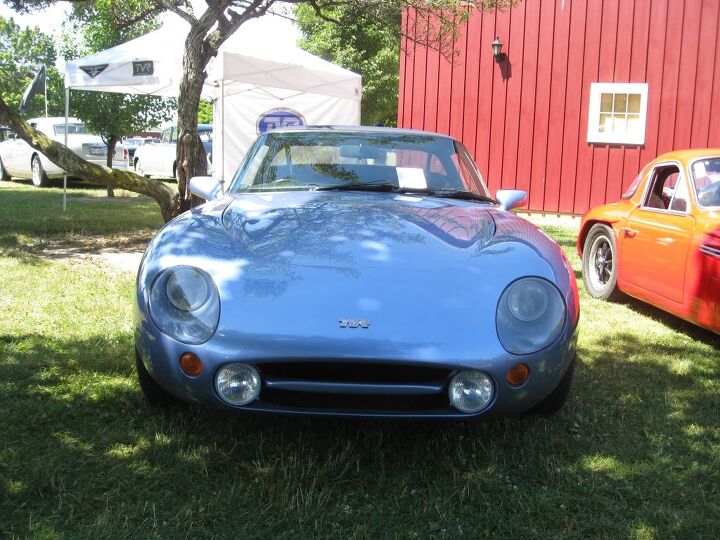

As the Marque is Revived, A Look Back at TVR's History and Cars

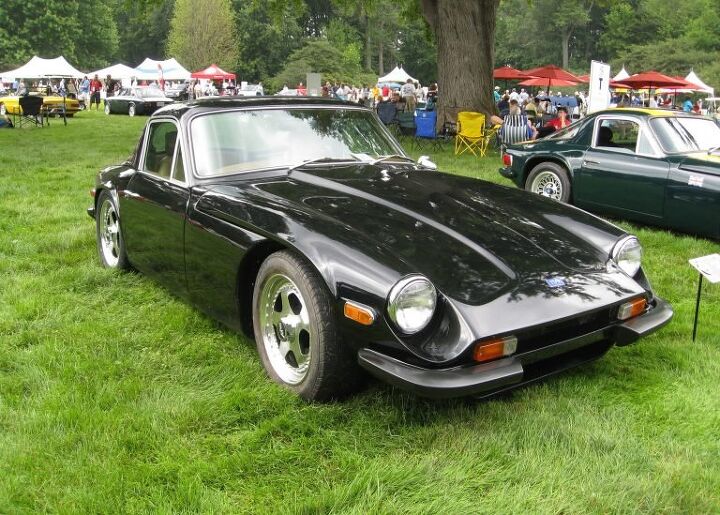

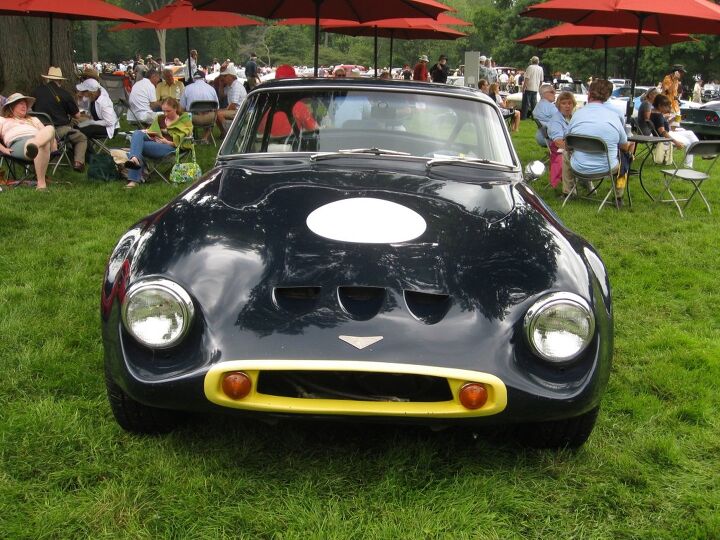

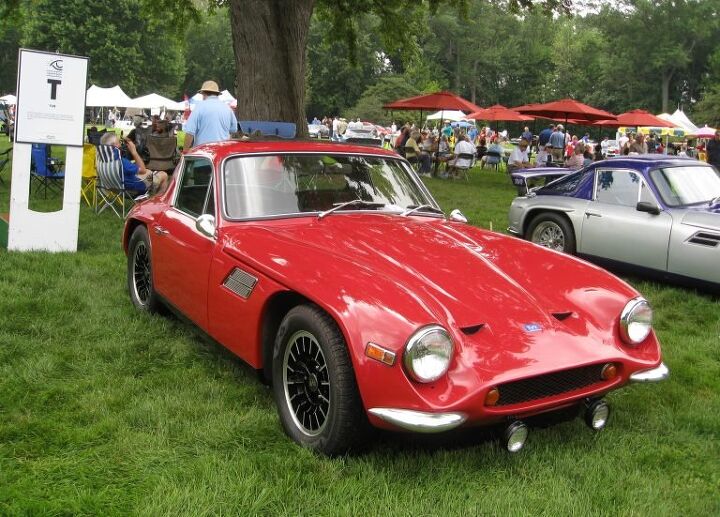

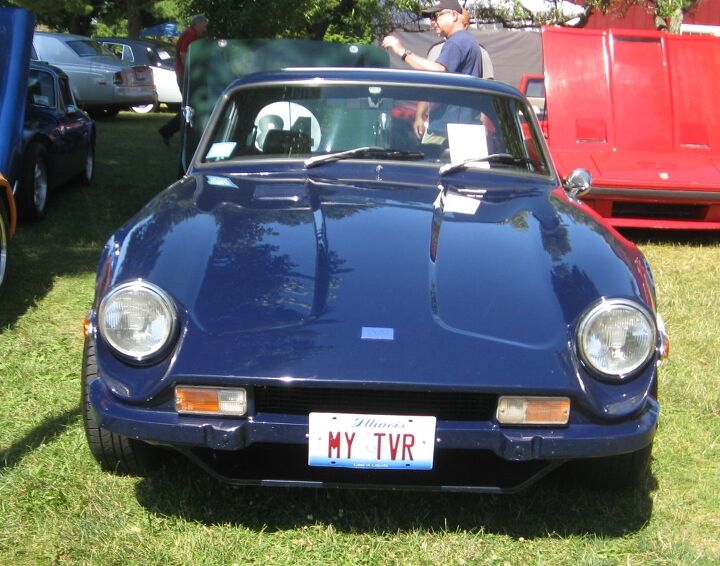

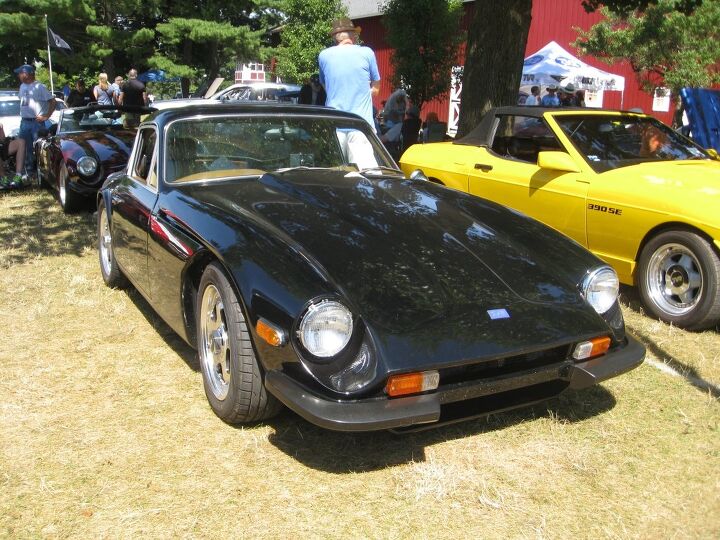

1963 TVR Grantura Mk III

There is the obscure, and then there is the arcane. When the revival of TVR was announced, with a grand touring car based on Gordon Murray’s iStream manufacturing technology, it is likely that more contemporary car enthusiasts were familiar with Murray than with TVR. Even most car enthusiasts have never heard of the marque. TVR is a specialist British sports-car maker that’s been around since the early 1950s. Over the years they’ve managed to produce a few thousand fiberglass-bodied cars with quirky styling, confusing names, and a passionate following despite repeated bankruptcies and numerous changes of management and ownership. Founder Trevor Wilkinson left the company in the mid 1960s, though the company retained its name, based on the letters of his first name.

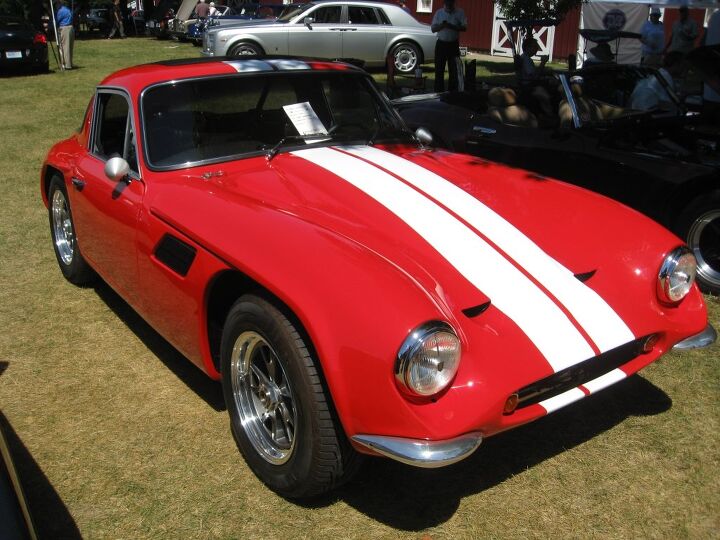

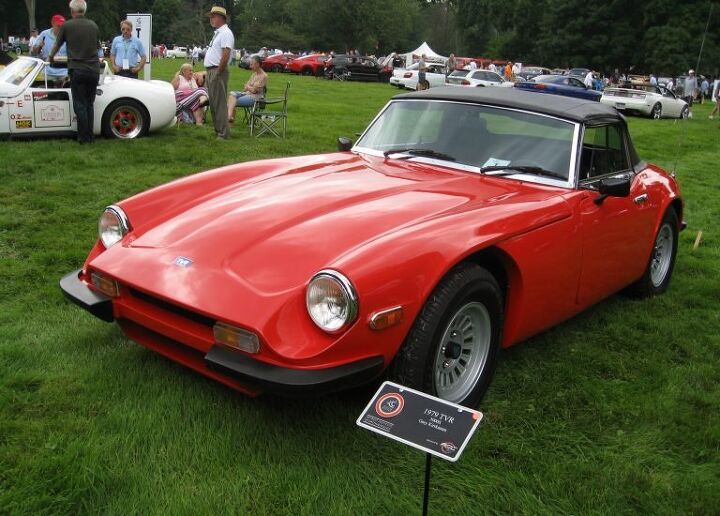

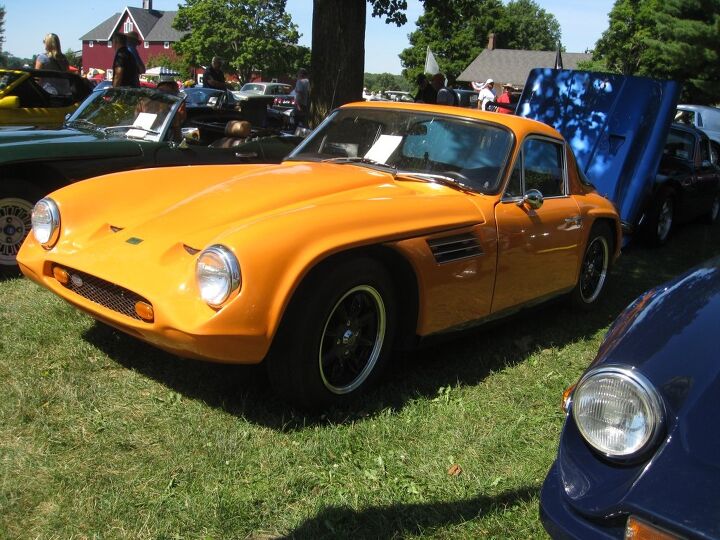

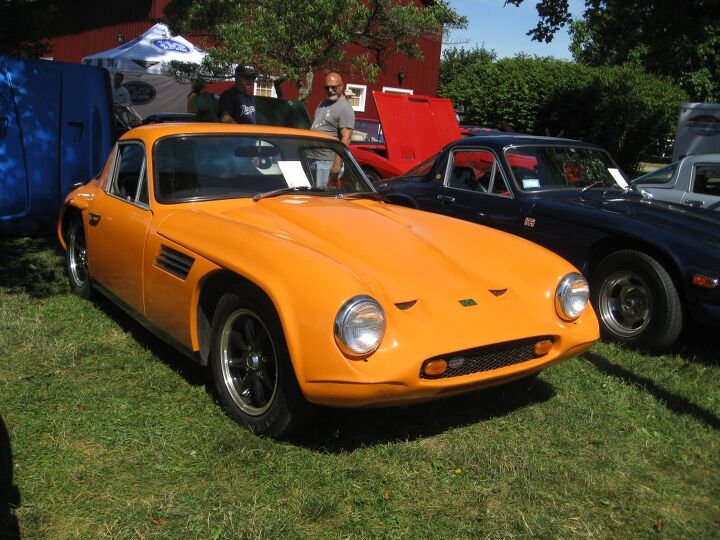

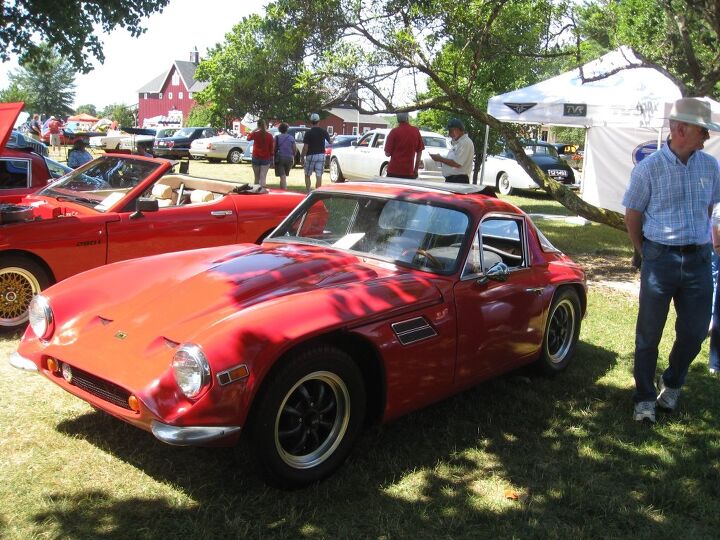

1965 TVR Griffith Series 200

After a series of specials, TVR’s first production car, the Grantura, was introduced in 1958. It had a tube space frame that surrounded a central backbone. Early Grantura’s used front and rear VW Beetle trailing arm suspensions and brakes from the Austin Healey 100. A variety of Coventry Climax, Ford, and MG engines were fitted. By the time the Mk III Grantura was introduced in 1962, it had a longer chassis with coil springs and independent suspension at all four wheels. The front end was restyled slightly and a little bit of chrome was added. Power was by MG 1.6 or 1.8-liter inline fours. That chassis was designed by John Thurner, who had bought an early TVR while working as an engineer at Rolls-Royce and liked it so much he quit his job and went to work for the sports car maker. The Mk III Grantura chassis would be used by TVR, with modifications, into the 1970s.

By the mid 1960s, Sydney Allard, Donald Healey, and Carroll Shelby had well proved that putting a powerful American engine in a lightweight British sports car was a winning combination. In the case of the Griffith TVRs, the combination almost killed the company. TVR started exporting chassis to America very early on in the 1950s. Jack Griffith was a Long Island Ford dealer who liked to race and he got his hands on a Grantura. Griffith dropped a 289 Windsor Ford V8 into his Grantura MkIII. Acceleration was even better than Griffith and Dick Monnich, an American associate of TVR, had hoped. The spindly chassis and standard brakes, however, were not up to the task, so David Hives, at the TVR shop back in Blackpool, modified John Thorner’s chassis to better handle the V8 and its power and built a second prototype with better brakes and handling. Satisfied with the results, the TVR works built three additional cars without engines and shipped them to Griffith.

That car was known as the Griffith Series 200. Plans were made for a Griffith 400 and Hives spent months sourcing components from other British car companies. A Griffith 600 was planned as well.

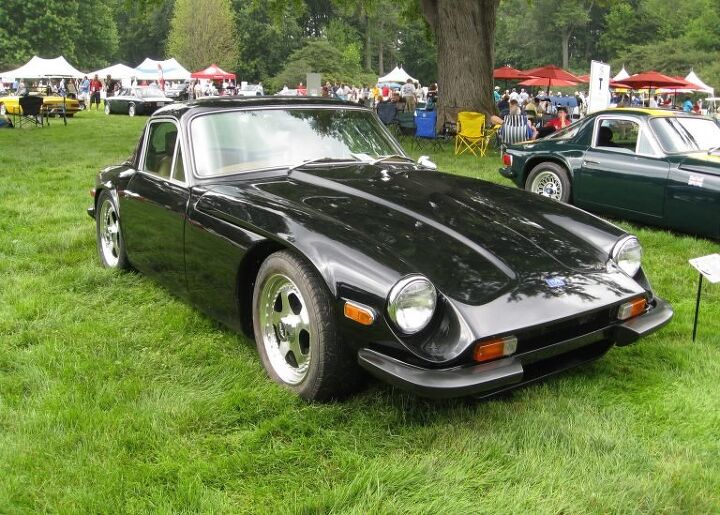

1971 TVR Vixen 2500 Coupe

In the spring of 1964, Hives went to America to join designer Robert Cumberford in styling a model and making the molds for what was hoped to be the Griffith 600. Hives and Griffith’s race mechanic George Clark also set up a small assembly line in Syosset, Long Island to install the Ford V8s into cars built by the TVR factory in the UK.

Unfortunately, 1964 did not turn out well for TVR. As one might expect from a tiny English car company in the 1960s, TVRs were not quite as reliable as VWs or Chevys. Customers started complaining. Then a dockworkers’ strike in the United States stopped the flow of engine-less cars to Griffith from TVR. Unable to fill orders, Griffith couldn’t pay Ford for the engines, so they cut off supply. Griffith also couldn’t pay TVR for cars already shipped to him. That put TVR, already in its usual precarious financial situation, beyond life support. In September, directors voted to stop production and close the factory. The company went into liquidation in late 1964.

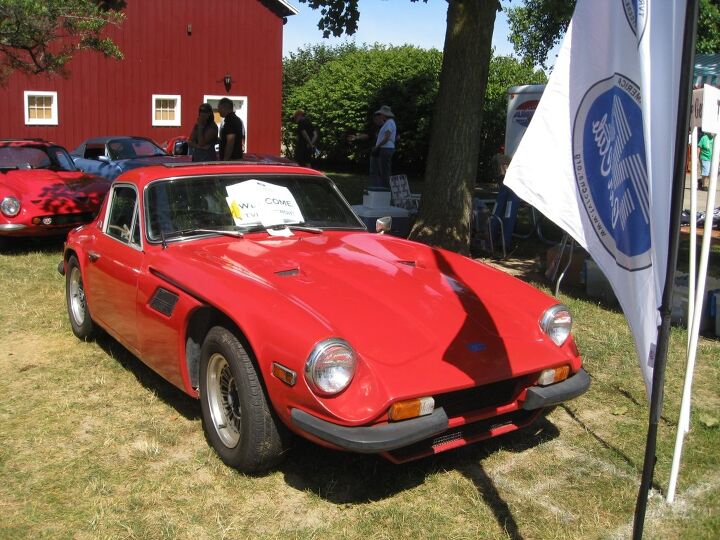

1971 TVR Vixen 2500

One might ask, if the styling was odd and the power was provided by off-the-shelf units sourced from other companies, what was the appeal of the TVR? Well, with tube frames and plastic bodies they were lighter and faster than the MGs with the same engine.

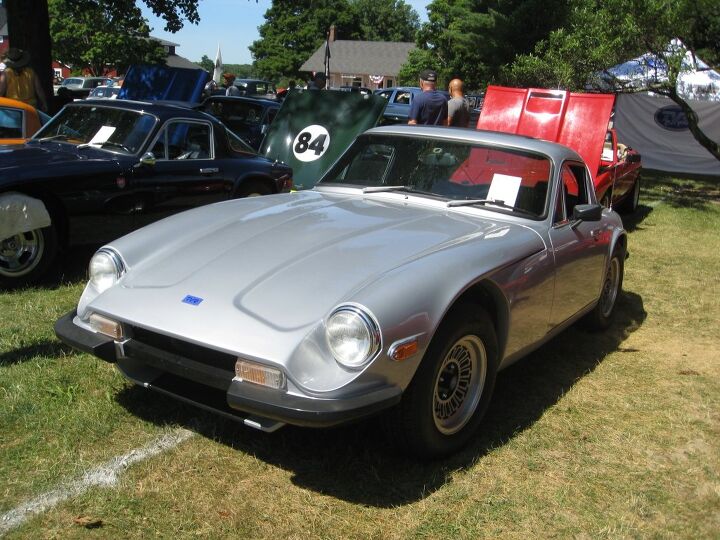

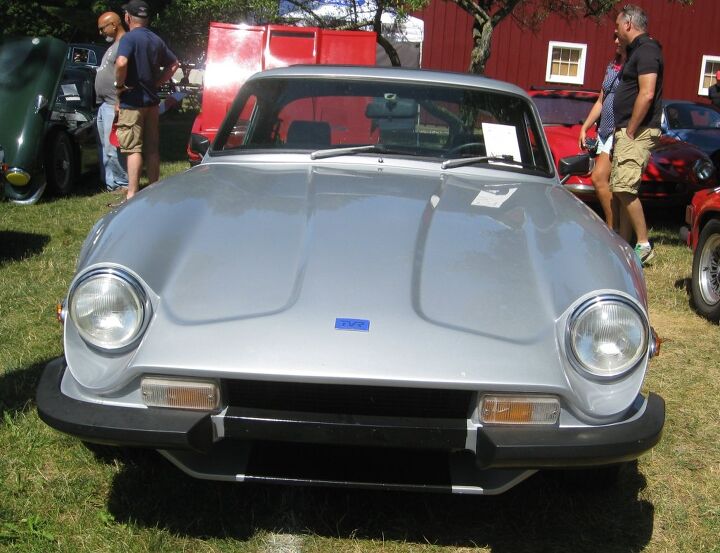

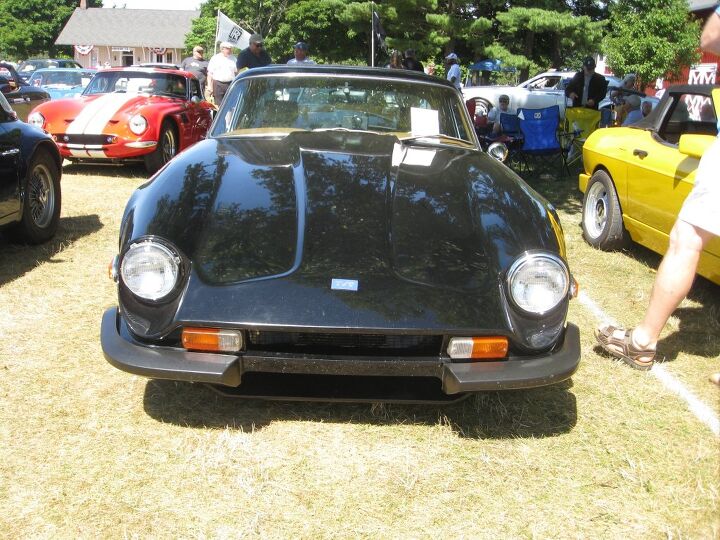

1977 TVR 2500M

To offset their losses of £2,000 worth of TVR stock in the 1965 bankruptcy, TVR distributor Arthur Lilley and his son Martin bought the assets of the company out of receivership and reorganized it as TVR Engineering Ltd.

1977 TVR 2500M

The company was in shambles. There were no outstanding orders, but there was outstanding debt to suppliers who needed to be compensated before production could begin again. Also, as they were being laid off, the previous employees had apparently stolen parts and vandalized equipment. The Lilleys hired new workers, put a management team in place and started producing the MkIII again.

In the meantime, a factory supported Griffith was doing well racing in America, generating much-needed positive publicity to offset the negative publicity generated by the crappy quality of the Griffith-finished cars. A new American distributor was set up and TVR Cars of America was established in 1967 with a small showroom and repair facility on Long Island.

1978 TVR 3000S

Plans to put the Trident, a new model with a stylish, less-dated body, into production were shelved when Martin Lilley failed to gain rights to the design. Production of the Griffith was stopped and the Tuscan V8 was introduced. It was not successful, though, and very few were built.

The Lilleys did manage to introduce a “new” TVR. The Vixen was first revealed at the British motor show in October of 1967 and generated enough new orders that the Lilleys decided to ramp up production for 1968, even though 1967 had shown a financial loss. The Vixen used the same tube-frame chassis as the Mk III 1800s, with double wishbone suspension fore and aft, and disc brakes up front. There were some minor styling changes but the primary mechanical difference was switching to the then new 1.6-liter version of Ford’s “Kent” block four-cylinder. Ford was less hassle to work with than MG and the engines were cheaper (and probably more reliable as well). Vixens were also fitted with the round taillights from the first generation Ford Cortina.

Though the Lilleys had experimented with a steel bodied concept, the Vixen used glassfibre reinforced plastic like other production TVRs.

For the Series 2 Vixens, introduced in 1968, that body, however, was now bolted to the longer-wheelbase Tuscan V8 chassis, rather than bonded as with previous TVRs. That made repairs much easier. More laminates were used to make the body stiffer and an attempt to improve panel fit was made. A better interior was fitted, and the steering wheel was mounted lower to address customer complaints. Slight styling changes were made to the hood/bonnet. With over 400 sold, the S2 Vixen was one of the better selling TVRs.

1978 TVR Taimer

The Series 3 Vixens had minor changes, while the S4 Vixens were transitional models that used the Vixen body shell and the later M Series chassis.

An economy model, the TVR 1300 was introduced in 1971. It used the 1296cc engine from the Triumph Spitfire. With just 63 horsepower and a top speed of 90, it was not popular and just 15 were sold.

The TVR 2500 (not to be confused with the later 2500M), marketed as the Vixen 2500 in the United States, was sold in 1971 and 1972. The car existed because Triumph’s 2.5-liter six was already certified by the U.S. EPA. The last 96 of 385 2500s that were built used the Vixen body on the M Series chassis.

For its next cars, TVR finally replaced John Thorner’s original space-frame chassis with one designed by Mike Bigland, an engineer and TVR dealer whose suspension modifications vastly improved the handling of the Thorner chassis cars. The new chassis was safer, more rigid, and cheaper to build. It would be the foundation for 1600M, 2500M, 3000M, 3000S, and Taimar, selling slightly less than 2,500 cars over nine years.

1979 TVR 3000S

The chassis has a center backbone with perimeter tubes, made up of both round and square 14- and 16-gauge steel tubing. Lilley invested in new fixtures that allowed TVR’s two chassis welders to make up to five frames a week. By leaving the oil film on the tubing from its manufacturing process, capping the ends and not using through-fasteners, TVR was able to offer a five-year guarantee against corrosion.

Using TVR’s traditional front mid-engine layout, with the engine behind the front axle, allowed Bigland to mount both the radiator and the spare tire in front of the motor. That not only freed up luggage space in the trunk, it helped with collision safety. As a matter of fact, when the UK’s Motor Industry Research Association crash tested a M Series car in 1971 it was the only car they tested that remained steerable after a 30 mph front collision.

Fully independent suspension was via double wishbones and coil springs all around. The differential carrier, suspension wishbones, and uprights were of TVR’s own design and manufacture but as with other specialist makers like Lotus, parts were sourced from bigger companies’ parts shelves. Brakes (11″ discs in front, 9″ drums in the rear) were from the Triumph TR6. A production Alford & Adler steering rack was connected to a British Leyland steering column. Motive force was provided by Ford, in the form of Kent fours and Essex V6s, and Triumph, using the TR6’s 2.5-liter inline-six.

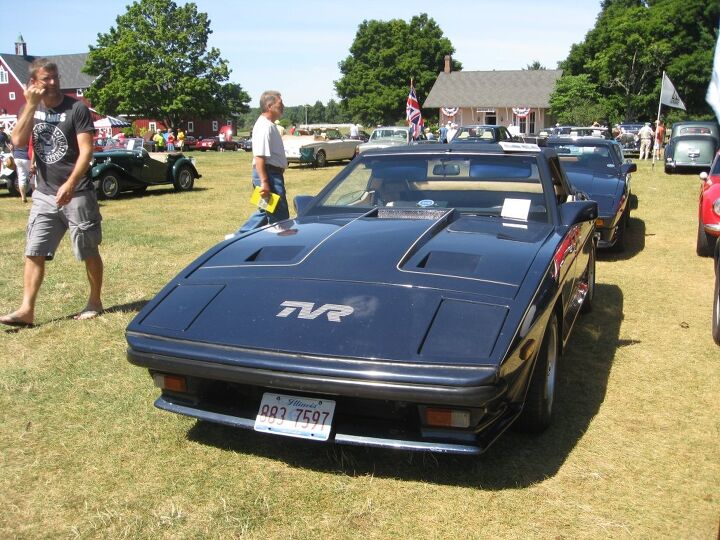

1985 TVR 380SE

The new cars got a newish body. To save money, the passenger cabin, including the doors, roof, front bulkhead, and Ford Consul windshield, remained the same. Bigland gave the bonnet/hood another restyling while Martin Lilley directed the shaping of a new rear end by company fiberglass specialist Joe Mleczek. Lilley also designed the new interior and trim. Depending on the models and how hot they ran, some M Series cars had vents on the hood and fenders.

Again, a variety of taillights were used, including Mk II Cortina lamps mounted upside down and switched left to right, Triumph TR6 taillamps, and stock square Lucas units. A variety of aluminum wheels were also offered. Chromed Triumph 2000 bumpers were used until 1974, when they were replaced with black foam – likely to comply with 1970s era bumper standards.

In January of 1975, several completed and nearly finished cars were destroyed when a fire broke out at the factory. The likely cause was faulty wiring on a 3000M factory demonstrator car (no Lucas jokes, please). Under the Lilleys, TVR tried to keep about three months worth of parts on hand and many of those were also destroyed in the fire. Sandblasters were used to remove soot but the sand ended up damaging equipment. Despite those setbacks and working without heat or electricity, TVR employees managed to get production running again, slowly.

1995 TVR Challenge Racer

The fire cut production to only ~150 cars that year and consequently only 20 cars were exported to the U.S. that year, crippling the brand in its most important export market.

Having kept pretty much the same general styling since the 1950s, by the late 1970s TVR cars were looking a bit dated. The need to comply with stricter safety and emissions standards were also an issue, so it was time for a completely new car. If you think that the TVR wedges look a bit like Lotus cars from the same era, there’s good reason for that. TVR owner Martin Lilley brought in a couple of Lotus alumni for the task. Oliver Winterbottom, who designed the 1970s era Lotus Elite four seater and its fastback derivative, the Eclat, rendered a new two-seat coupe body. Ian Jones designed the tube based space-frame chassis, now powder coated for better corrosion resistance.

A prototype, powered by a 2.8-liter German Ford V6, was fabricated in early 1979, but development was hindered by a lack of funds – a situation that was made worse when the U.S. government seized and impounded £100,000 worth of M Series cars for failing to meet pollution standards.

Again TVR used components from other manufacturers, in this case mostly Ford. Front suspension and steering came from the Cortina (rear wishbones were in-house designs), transmissions came from the Granada, Sierra and Cortina, and the front brakes were Granada units. For the rear end, TVR borrowed a popular American hot-rod swap, using the differential and inboard disc brakes from the Jaguar XJ-S. Engines were the 160 horsepower fuel-injected Ford Cologne 2.8-L V6 and, in just a few Tasmins, the 2.0-L four that was used in the Ford Pinto.

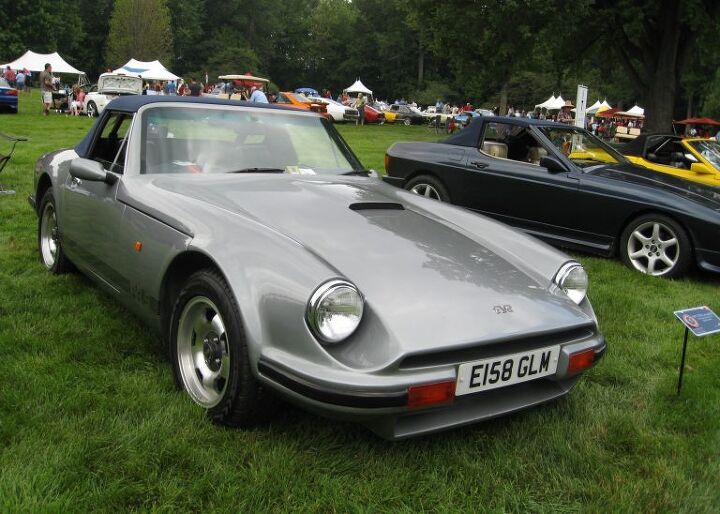

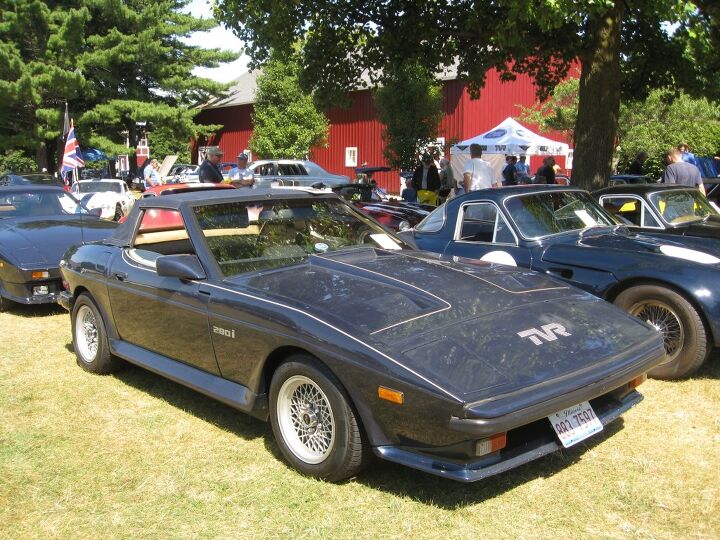

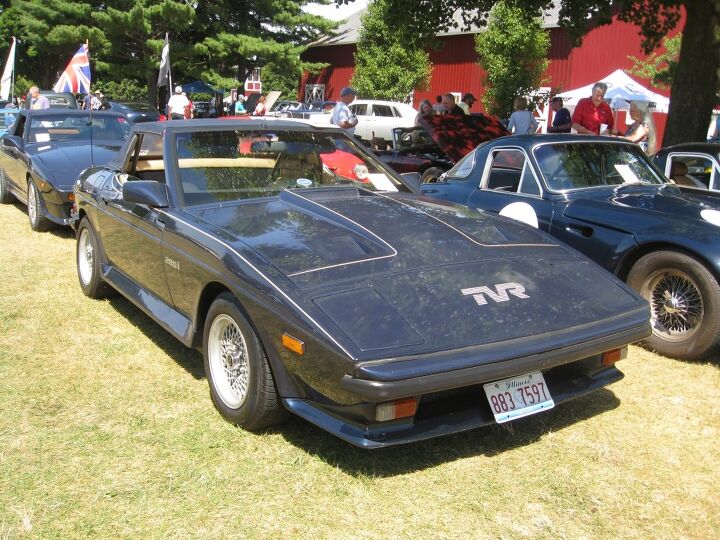

1987 TVR 250I

The finished car, introduced in 1980 as the Tasmin, got favorable reviews for its handling but didn’t sell well. Some blame the price, £5,000 more than the Taimar, while others blame Winterbottom’s styling. Even Martin Lilley was quoted as saying the styling was “a big disappointment”, but because of sunk costs and time constraints they decided to go forward. Sales were also disappointing, a situation exacerbated by the recession of the early 1980s in the UK. TVR sales in 1982 plunged to just 121 cars.

One more time TVR faced financial ruin. In December of 1981, Martin Lilley sold control of TVR to Peter Wheeler, a TVR customer and wealthy businessman.

Prior to the change in ownership, a series II wedge was introduced with significant improvements and a new name, the TVR 280i. The name was a reference to the 2.8-liter V6, which having been already certified by Ford to meet pollution regulations in the United States, allowed TVR to return to the U.S. market for the first time in six years. Relationships with TVR’s U.S. distributor, though, deteriorated, and by 1987 rising warranty costs and a more than 500% increase in the cost of their liability insurance in America eventually convinced Wheeler to withdraw from the U.S.

1987 TVR 350I

In total, 1,167 V6 cars were produced. Wheeler didn’t think the V6 cars were fast enough, so with some changes to the chassis the 190-horsepower, 3.5-liter Rover V8 (originally a Buick design) was dropped into the 280i, making it the 350i. Zero to sixty times dropped to 6.3 seconds, with a top speed of 130 mph. In addition to more speed, sourcing the engine from Rover helped with sales in the Arab world, where Ford’s business in Israel was an issue.

In all, about 1,000 350i cars were made.

In 1984, the 390SE was introduced. Andy Rouse, a Rover tuner increased the displacement of the Rover V8 to 3.9 liters, blueprinted the engine and fitted high lift camshafts, cylinder heads with improved gas flow, larger valves, and Cosworth machined pistons. A claimed 275 horsepower was produced. To cope with the additional power, a beefier clutch, limited-slip rear end, and wider tires were used.

The front end got a deeper air dam and in back they added an underbody airfoil that looks a bit like the car is wearing a diaper, but does help with the aerodynamics. Flared wheelarches gave the 390SE a more aggressive look and allowed for bigger 15″ wheels. The larger wheels accommodated larger ventilated front brake discs.

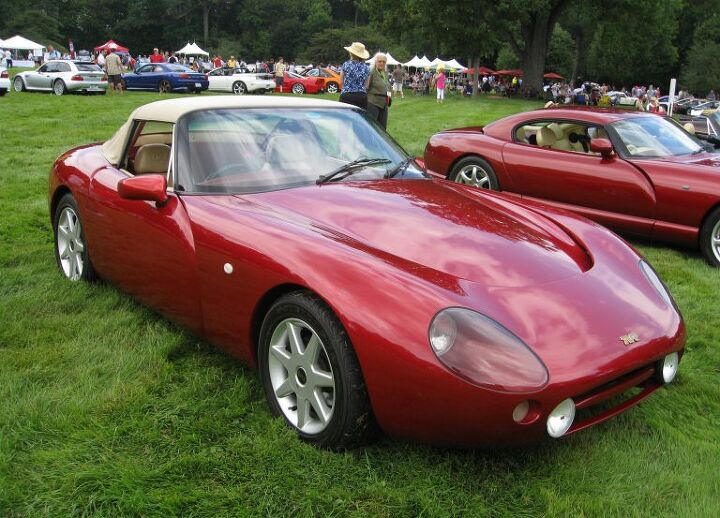

1987 TVR Convertible

TVR jobbed out the modifications for the Rover V8 to a number of companies but most of them were assembled by North Coventry Kawasaki, which was later bought out by TVR and made into TVR Power. About 100 390SE cars were made.

Though the TVR Tasmin and related cars mostly came to market under Peter Wheeler’s ownership of the company, they were designs that dated to Martin Lilley’s era. In the 1990s Wheeler put his own stamp on TVR, first with with the Griffith and Chimaera and later using TVR’s own AJP8 V8 engine with the Cerbera and the inline TVR Speed Six in the Tuscan.

The Griffith, later called the Griffith 500, was the first Wheeler era TVR, introduced in 1991. It had an entirely new backbone space frame and a completely new convertible body. Like its namesake of the 1960s, it had V8 power, in this case the 4.0-liter, 240-hp version of the Buick/Rover V8, powering the rear wheels through a five-speed manual gearbox. Later versions would feature the TVR developed 5-liter version of the Rover eight with an additional 100 hp. At just 2,310 lbs, performance in either case was at least brisk. Because of a complete lack of electronic stability systems (Wheeler said he didn’t think they were necessary, though they may also have been out of TVR’s technical or financial reach), a high power to weight ratio, and very quick steering, Wheeler era TVRs used gas pedals with exceptionally long amounts of travel, to help keep drivers from getting into trouble.

1995 TVR Chimera 400HC

The Griffith was produced in smaller numbers than its near mechanical twin, the Chimaera, which had a longer wheelbase, a softer suspension, and a different body. The Chimaera was seen more as a grand tourer and today we’d say that the Griffith was more track focused.

1995 TVR Chimera 400HC

By the mid 1990s, the Rover car company was purchased by BMW, and Peter Wheeler was concerned that the Bavarian company might discontinue the production of the Rover V8. As it worked out, that motor stayed in production until 2005, but Wheeler decided to pursue manufacturing TVR’s own powerplants and commissioned Al Melling Sports Cars to design what would be the AJP8. Borrowing architecture from Formula One, the AJP8, also known as the Speed Eight, was a 75-degree V8 with a flat plane crankshaft. With 4.2 liters of displacement it produced 360 horsepower, one of the highest specific outputs of the naturally aspirated engines of the day. Eventually a 4.5-liter version would produce 440 hp. Going with a narrow vee made the AJP8 compact and its all-aluminum architecture resulted in a weight of just 267 lbs. Apparently some of those claimed power figures were a bit optimistic, with production versions of the higher-displacement engines needing changes to the ECU, induction, and exhaust to meet advertised power levels.

Happy with the results of the AJP8 program, Wheeler commissioned the Speed Six, a 4.0-liter slanted inline-six with four valves per cylinder. That engine would power the Tuscan, introduced in 1996, but would prove to be unreliable, with many of the engines needing to be rebuilt under warranty.

1996 TVR Cerbera Speed 8

The AJP8 was intended for the Cerbera, TVR’s first four-seater. Though it’s much like a conventional 2+2 layout, with small back seats, TVR called this “3+1” seating, because the front passenger seat can move farther forward than the driver’s seat. The Cerbera got its own styling and own interior, distinct from the Chimaera and Griffith, though there’s a family resemblance. Weight was again very low, a claimed 1,110 kg, though real-world scales put Cerberas anywhere between 1,060 and 1,200 kilograms.

1996 Cerbera Speed 8

In 2000, the Cerbera’s styling was revised so the headlights would match the rather unusual headlamp array of the Tuscan.

In mid 2004, a Russian national named Nikolay Smolensky bought TVR from Peter Wheeler for a reported £15 million. Smolensky was just 24-years-old at the time. Two years later, when demand dropped and production plummeted from 12 cars a week to just three or four, there were layoffs and TVR announced that they were moving the factory to more-modern facilities. Wheeler still owned the current factory and was planning on redeveloping the real estate. Later that year Smolensky said body production and final assembly of TVRs would be moved to Turin, Italy, though engine production would remain in England.

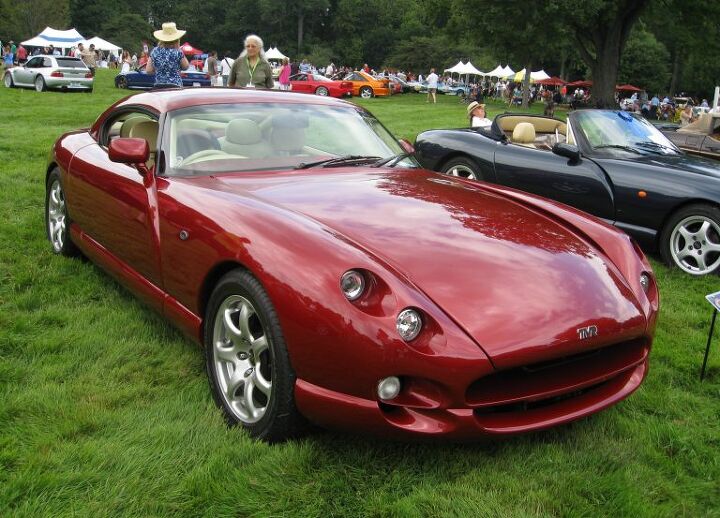

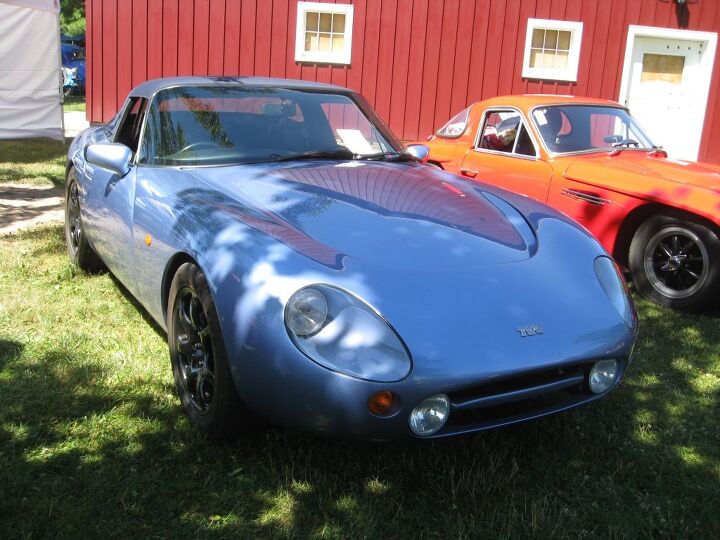

TVR Griffith 500

In reality, Smolensky was reshuffling TVR’s financial house of cards, splitting the company into a number of different firms that he controlled. When one of those companies, Blackpool Automotive, which owned the manufacturing assets, became insolvent, Smolensky himself bought it out of bankruptcy.

Smolensky continued to control the company, announcing that production would restart in 2008 with a target of 2,000 cars. Though a new Sagaris model was announced, nothing happened. In 2010, Gullwing, a German company with a minority interest in TVR said that they’d be producing an all-new TVR starting later that year. Again nothing happened.

2019 TVR Griffith 500

Finally, in June of 2013, TVR Automotive Ltd, a new company led by UK technology businessman Les Edgar, announced that they had acquired all of Smolensky’s TVR related holdings. Since then the company has reestablished sales of spares as well as service for all TVR models. Edgar later announced a technical partnership with famed designer Gordon Murray. It’s appropriate that at the 2017 Goodwood Revival, the revived TVR company revealed the fruits of that partnership, the Griffith 500. Based on Murray’s iStream carbon-fiber-intensive manufacturing process, the new Griffith 500 will be a 200-mph grand tourer, powered by a Cosworth-tuned naturally aspirated 5.0-liter Ford V8, and it is scheduled to go on sale in 2019.

As obscure, or arcane, as TVR is, the marque has an enthusiastic following. The 2015 Eyes On Design show at the Edsel & Eleanor Ford Estate and the 2016 Mad Dogs and Englishmen show at the Gilmore Museum both had TVR as featured classes, which is how these photographs came to be taken.

Image Source: Ronnie Schreiber

1963 TVR Grantura Mk III

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- EBFlex It’s ironic that the typical low IQ big government simps are all over this yet we’re completely silent when oil companies took massive losses during Covid. Funny how that’s fine but profits aren’t. These people have no idea how business works.

- Ajla Goldman Sachs 🥂

- Rna65689660 DVR and watch all that are aired. Has been this way for 40 years.

- Kwik_Shift_Pro4X The only car racing I'll watch is rally car.

- Offbeat Oddity The price is definitely too high, but this generation of Accord has still been very reliable- not far off from the Camry. I believe the CVTs in these have held up very well, so while not ideal, it wouldn't deter me- the mileage is just way too high.

Comments

Join the conversation

Great article! I learned of TVR in the late 1960s when one of my college roomies sold his '62 TR4 to a TVR dealer in New Jersey. Somehow, I ended up going with, and we sat in, I believe, a Vixen. I remember being impressed with a row of toggle switches, including one for the electric fuel pump.

I have always loved the 60s TVRs. I think a Griffith would make an outstanding kit car. I would love to have one with a modern four or V6.