IIHS Wants Bigger, Harder Crashes for Its Side Impact Tests

While the Insurance Institute for Highway Safety (IIHS) has gradually evolved its testing procedures since its inception, it has hit the accelerator over the past few years, eager to crash into a new era of knowledge… Alright, so it actually just wanted to assess problematic crash trajectories and headlight safety for insurance companies. Still, they’ve been making meaningful changes in a bid to boost overall safety.

On Thursday, the institute said it plans to continue evolving its crash-test procedures. It claims it’s gotten so good at developing side-impact assessments, “the current side ratings no longer help consumers distinguish among vehicles or point the way toward further improvements.”

The solution? Slam bigger, heavier items into a vehicle’s profile and see what happens.

“This is an opportunity to build on what we’ve learned in more than 15 years of side testing,” said IIHS Senior Research Engineer Becky Mueller. “We’ll update the things that need updating, but we don’t need to throw out the things that still work well.”

Basically, the group feels the current metrics it uses to assess damage/injury are fine. It plans to use the same dummies and equipment inside the victim car. The only real change is the ferocity of the impact, as it believes the old standard was working so well that the automotive industry no longer has any incentive to make additional safety improvements.

From IIHS:

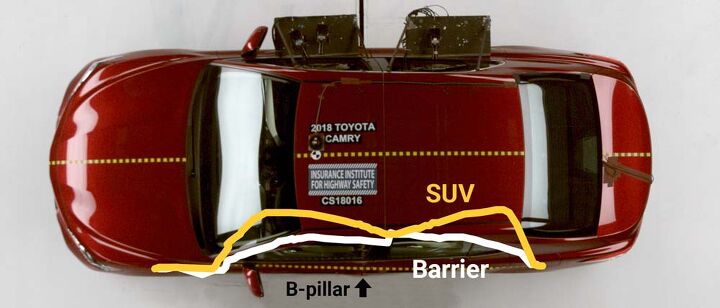

The IIHS [side] test proved more challenging than the NHTSA test because the movable barrier mimicked the height and shape of the front end of the typical SUV or pickup on the road at the time. IIHS also used dummies representing a small woman or 12-year-old child. The combination of these two things meant that the barrier struck the vehicle at about the height of the dummies’ heads.

To achieve a good rating in the test, automakers strengthened side structures and equipped vehicles with head-protecting side airbags ahead of a federal regulation that made them essentially mandatory. Only about 1 in 5 vehicles tested earned good ratings in the beginning. Today, 99 percent of rated vehicles earn a good rating, and the remainder are acceptable.

The improvements translated into lives saved. A 2011 study of 10 years’ worth of crash data found that a driver of a vehicle rated good is 70 percent less likely to die in a left-side crash than a driver of a vehicle rated poor.

The IIHS is looking for gaps in its testing, noticing that hitting an automobile with a mobile barrier (which can be crashed repeatedly) doesn’t behave exactly the same as striking a car with a real SUV. Barriers create a more uniform impact zone and can often push a car away. But a vehicle with a less uniform surface can create hot points that push further into the victim car, potentially even pitching it toward the impact zone. They’re also likely to weigh more than the 3,300 pound barrier.

While still in the exploratory phase, the IIHS is toying with the idea of increasing the barrier’s overall weight to 4,200 pounds (the average weight of a 2019 model SUV), reshaping its face, and upping impact speeds to 37 mph (from 30). Muller said the combination generates 82 percent more energy than the group’s current side rating test — likely forcing a bunch of previously good-rated vehicles into the gutter.

“Our goal is to create a barrier that creates the same type of damage as a typical late-model SUV or pickup would in a 37 mph crash,” Mueller explained. “That way, we can be confident that the changes automakers make in hopes of achieving good ratings in the new side test will result in better protection for vehicle occupants in real-world crashes.”

[Images: IIHS]

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- MaintenanceCosts Whenever the topic of the xB comes up…Me: "The style is fun. The combination of the box shape and the aggressive detailing is very JDM."Wife: "Those are ghetto."Me: "They're smaller than a Corolla outside and have the space of a RAV4 inside."Wife: "Those are ghetto."Me: "They're kind of fun to drive with a stick."Wife: "Those are ghetto."It's one of a few cars (including its fellow box, the Ford Flex) on which we will just never see eye to eye.

- Oberkanone The alternative is a more expensive SUV. Yes, it will be missed.

- Ajla I did like this one.

- Zerofoo No, I won't miss this Chevrolet Malibu. It's a completely forgettable car. Who in their right mind would choose this over a V8 powered charger at the rental counter? Even the V6 charger is a far better drive.

- Offbeat Oddity Nope, I won't miss it. I loved the 2008-2012 Malibu, but the subsequent generations couldn't hold a candle to it. I think the Impala was much more compelling at the end.

Comments

Join the conversation

Could this new testing be funded by the car makers who gave up sedans? I'm sure they are eager to prove how right they are.

Hey, strengten the hit cars by adding more steel. Hence making the cars crashing into them, also such strengthened, heavier. Requiring more steel and more weight.... If endangering others lives imposes a cost on them, the optimal equilibrium is best found by ensuring the cost is be borne by the guy doing the imposing. Not by way of some arms race trying to pawn the cost off on the guy being passively hit. In the contest of this, that means crashing the vehicles, then tacking on a fee to those vehicles who do more damage to those they hit. And handing that fee back in the form of a subsidy, to those vehicles who do less. Do that, and you just about may get somewhere halfway efficient and non silly.