Buckeye Pride – Acura's Performance Manufacturing Center

A full quarter of the names currently on The Truth About Cars masthead grew up in the Buckeye state, including yours truly, and plenty of contributors, past and present, have called The Heart of It All home.

The preceding message concludes the advertising section, brought to you by the Ohio Department of Tourism.

I mention this to remind the reader that there is more to the American auto industry than Detroit. Indeed, Honda has been building vehicles in Ohio for nearly forty years, with an engine plant, a transmission plant, and now three vehicle assembly plants. Journalists were given the opportunity to tour the newest facility, the Performance Manufacturing Center, to see how Acura turns out the exotic NSX – and now, the less-exotic but still remarkable TLX PMC Edition.

(Disclaimer: I drove to Marysville, Ohio from my nearby home. Acura fed me lunch.)

For three years, Acura has been building the hybrid NSX in a repurposed parts distribution facility adjacent to the four million square foot Marysville Assembly Plant, which churns out hundreds of cars like the Accord, ILX, TLX, and CR-V every day. By comparison, a serialized number badge about to be installed on a hand built NSX while I was touring had a number 2217. That’s less than a week’s production on one of the two lines at Marysville (MAP to insiders). You get the feeling that Honda/Acura executives took a look at the dismal NSX numbers and at the skill level of the team at PMC, and decided to do something about the disconnect. And thus, the PMC Edition TLX.

As a refresher, the TLX PMC Edition is basically a loaded TLX A-Spec, paired with the safety and luxury features on the Advance package — but finished at the Performance Manufacturing Center, with unique paint and trim. It’s limited to 360 cars, after which the Performance Manufacturing Center will start production on a similarly trimmed MDX PMC Edition.

Honda and Acura, per Andrew Quillin from Acura PR, “always intended to use PMC as a testbed” for new products and manufacturing techniques. The low volume certainly allows for a lower-pressure environment to try new things. Down the street at Marysville Assembly, for example, an Accord rolls off one of the two lines every 55 seconds. At max capacity, Marysville can turn out 180 of the TLX every day. Conversely, on the day we visited, the Performance Manufacturing Center expected to complete six TLX PMC models.

We didn’t see any unpainted TLX sedans, but a pair of MDX bodies-in-white sat off to the side after delivery from the East Liberty Plant — just a few miles northwest of PMC. This is how the TLX would be delivered to PMC from Marysville Assembly — with a base primer coat, but otherwise in need of final paint and assembly.

While there are a few robots at PMC — including one that applies a precise bead of windshield adhesive, much of the work is completed by hand. Here we see two workers lifting the glass and placing it precisely by hand with the help of suction cups, much as your friendly local window shop does when the neighbor kid errantly tosses a baseball.

As the PMC was initially meant for a low-volume supercar, the factory was designed for ultimate flexibility. No conveyor belts run through the facility, as each car is moved through the various stations by hand. Here, we see a pair of technicians gradually using a hydraulic lift to raise the engine, transaxle, and front suspension into place, gently guiding everything in by hand.

As the NSX is primarily made from aluminum, carefully starting each fastener by hand is critical to minimize the chance of cross-threading. That process carries over to the PMC editions. Note the torque wrench, which lights up and gives haptic feedback to the operator once each bolt is torqued to spec. Each torque wrench is connected via Bluetooth to computers that log each torque value and link it to the VIN of the car. Should quality issues arise, PMC will always be able to refer to the torques for every car.

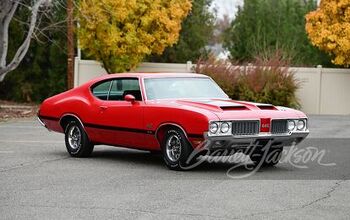

Much of the time involved in getting these limited production models ready is in the paint process. Here we see a gaggle of TLX wearing the gorgeous Valencia Red Pearl exclusive to the NSX and the other cars built at PMC.

Here, a glass-lined paint booth allows customers taking a PMC tour to see their car being painted. The Valencia Red Pearl on the TLX PMC wears up to 15 layers of paint, as well as tinted clearcoat to give even more depth to the finish.

After paint bakes and cures for a day, craftsmen work to hand polish the finish under intense lighting.

The alignment bay is one where the technicians get to sit down on the job. After all, an alignment on the NSX takes roughly 45 minutes. Thus Honda designed this adjustable seat beneath the alignment platform to make the job less of a strain.

Unlike at other Honda facilities, no PMC car leaves the building until it’s being delivered to the dealer. That means no outdoor testing that could mar the expensive paint. A four-wheel chassis dynamometer allows the car to be driven in a controlled environment, all while calibrating the all-wheel drive system and the vehicle stability control. Note the retractable fume hood behind the car — this raises from the floor to extract all exhaust gases.

After the dynamometer, the car drives forward into another inspection bay, again with intense lights. Beyond inspecting the finish, the car is tested on a four-post shaker rig to ensure the suspension is up to the challenge of all sorts of roads. It probably would have been cheaper for Acura to drive each car down US 33 twenty miles to Columbus, where the always-under-construction interstates often resemble a teenager’s acne-riddled forehead — but, again, that paint. Beyond the shaker rig is a car wash — both for a wash and to check for any water leaks. At that point, the car is ready for delivery.

We did get to see a few NSX bits on the tour that was primarily meant to highlight the TLX PMC, including the robotic MIG welders here joining various subassemblies of the aluminum chassis.

Over 900 MIG welds go into each NSX frame, along with 250 self-piercing rivets to join dissimilar metals like the steel structure over the doors. Here, Susan Dulik, quality assurance manager, shows off a completed NSX spaceframe.

Oh, and for inspiration, a first-generation NSX Zanardi Edition sits in the lobby.

In a prior career, I spent a good bit of time working as a supplier in several factories in many industries, including the automotive industry. Years ago, I had nearly free rein to walk through the Marysville and East Liberty Honda plants as part of that job, working with line workers and engineers. The environment within PMC is uniquely Honda, and yet so very different.

While I never saw line workers in the mainline Honda plants looking bedraggled by the work they were doing, there was clearly no time for chit-chat considering the pace of work. Conversely at PMC, everyone looked relaxed. Not slacking, by any means, but working at a comfortable pace and putting plenty of pride into their craftsmanship. Nearly everyone at PMC has twenty years with Honda at other factories, so they were the best of the best in their old roles and have moved onto this selective position in the highest profile Honda facility in the world.

PMC is a unique blend of high-tech manufacturing and old-school craftsmanship. The cynic within me wants to say the PMC edition TLX and MDX are simply busy work to keep these experienced workers doing something productive while Acura waits for more NSX orders, but after touring the plant and talking to the workers, I see much more than that.

Acura’s Performance Manufacturing Center is a showcase for what Honda can do, and more importantly, a showcase for what the best American workers can do when given the chance. That those best American workers happen to not be in Michigan warms this Buckeye heart.

[Images: © 2019 Chris Tonn]

Some enthusiasts say they were born with gasoline in their veins. Chris Tonn, on the other hand, had rust flakes in his eyes nearly since birth. Living in salty Ohio and being hopelessly addicted to vintage British and Japanese steel will do that to you. His work has appeared in eBay Motors, Hagerty, The Truth About Cars, Reader's Digest, AutoGuide, Family Handyman, and Jalopnik. He is a member of the Midwest Automotive Media Association, and he's currently looking for the safety glasses he just set down somewhere.

More by Chris Tonn

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Bill Wade I was driving a new Subaru a few weeks ago on I-10 near Tucson and it suddenly decided to slam on the brakes from a tumbleweed blowing across the highway. I just about had a heart attack while it nearly threw my mom through the windshield and dumped our grocery bags all over the place. It seems like a bad idea to me, the tech isn't ready.

- FreedMike I don't get the business case for these plug-in hybrid Jeep off roaders. They're a LOT more expensive (almost fourteen grand for the four-door Wrangler) and still get lousy MPG. They're certainly quick, but the last thing the Wrangler - one of the most obtuse-handling vehicles you can buy - needs is MOOOAAAARRRR POWER. In my neck of the woods, where off-road vehicles are big, the only 4Xe models I see of the wrangler wear fleet (rental) plates. What's the point? Wrangler sales have taken a massive plunge the last few years - why doesn't Jeep focus on affordability and value versus tech that only a very small part of its' buyer base would appreciate?

- Bill Wade I think about my dealer who was clueless about uConnect updates and still can't fix station presets disappearing and the manufacturers want me to trust them and their dealers to address any self driving concerns when they can't fix a simple radio?Right.

- FreedMike I don't think they work very well, so yeah...I'm afraid of them. And as many have pointed out, human drivers tend to be so bad that they are also worthy of being feared; that's true, but if that's the case, why add one more layer of bad drivers into the mix?

- ChristianWimmer I have two problems with autonomous cars.One, I LOVE and ENJOY DRIVING. It’s a fun and pleasurable experience for me. I want to drive my cars, not be driven by them.Two, if autonomous cars have been engineered to a standard where they work 100% flawlessly and don’t cause accidents, then freedom-hating governments like the POS European Union or totally idiotic current German government can literally make laws which ban private car ownership in their quest to save the world from climate change bla bla bla…

Comments

Join the conversation

Randomly-selected customer standing in front of randomly-selected Honda product on randomly-selected Honda dealer lot: "So the company that built this, knows how to build quality vehicles?" "Yeah." "Huh."

Unrelated to the article, but driving from the southwest corner of Ohio to the northeast corner is a seemingly never-ending slog.