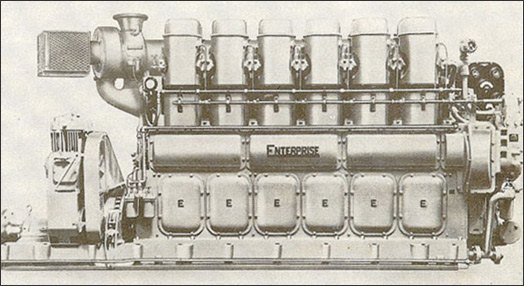

There's No Replacement For Displacement: 10,000 Cubic Inch Enterprise DSG-36 Diesel Fires Right Up After 30 Years

It does sounds like it should be the name of a spaceship on Star Trek but the Enterprise DSG-36 engine was made for more earthbound vessels. Enterprise Engine and Foundry dated back to the 19th century and they started building engines for stationary and marine purposes in 1917. Located near San Francisco, they were known for “their very heavily constructed four-stroke cycle diesels that had operating speeds on the lower end of the medium speed range.” The DSG-36 is a six cylinder four cycle diesel with a 12 inch bore and a 15 inch stroke. If I remember my geometry, that works out to 1.7 liters of displacement per cylinder, over 10,000 cubic inches total. In normally aspirated form it was rated at over 600 horsepower @ 600 rpm and with a turbocharger, more than 900 hp. During World War II, Enterprises engines were in high demand by the military and some can still be found in marine service. From the landscape in the background and the patina on the engine, this particular Enterprise DSG-36 hasn’t been near water for a while. It looks like it was used to run a generator, perhaps having been purchased as war surplus. Enterprise’s reputation for heavy duty construction appears to have been well earned. According to the poster on YouTube, it hadn’t been started in 30 years and it seems to have started right up. Time to call the Blastolene boys.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can dig deeper at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks for reading – RJS

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Comments

Join the conversation

I see your DSG-36 and raise you a V-2: https://www.youtube.com/watch?v=n_aDMqFrUV8 It is a smaller displacement, but it's mounted on a vehicle that moves under its power, so there.

How about this marine diesel for the container ship Emma Maersk. Look at the size of this shaft! http://gcaptain.com/emma-maersk-engine/ They say that shaft is a bad mu (Shut your mouth) I'm just talking 'bout shaft.

When I read the book of yachts and Men by William Atkins, It was fascinating to read that he often designed engines for the large yachts he designed and sometimes even built parts of the engine in his own machine shop, the early days of US engineering were a little different than today. As I recall he described the stroke of one of the engines in feet rather than inches, thats one I would have liked to see running.

Was I the only one watching how the dogs were completely unimpressed by this event. Neither fear nor excitement.. meh.