Buying Into Nanny-State Safety Diktats: Dual-Circuit Brakes For the A100

Ralph Nader’s Unsafe at Any Speed was published in 1965. For the 1967 model year, cars and light trucks sold in the United States were required to have a dual-circuit brake system, so that a single hydraulic leak anywhere in the system would not result in total brake failure. Real drivers knew that they could come to a complete, safe stop using the emergency brake— that’s right, for emergencies— but that wasn’t enough for the feds. They rammed dual-circuit brakes down the throats of the American public, adding at least several dozen dollars to the cost of a new car. My Dodge van is a ’66 model, which means it was the last year for the single-circuit brakes that gave our forefathers their moral strength (though not as much strength as their forefathers, who relied on mechanical brake actuation instead of hydraulics), and a lifetime steeped in Naderite propaganda has convinced me that I’m better off with some margin of hydraulic safety. Upgrade time!

Rocket Surgery Racing Renault 4CV team captain Rich gave me a coupon for brake-line assistance for my birthday, so I decided it was time to take him up on the offer.

The new 1967-grade dual-circuit master cylinder cost well under 50 bucks, and new brake hoses plus some line and fittings didn’t add much more to the cost of the project. This would be an all-sweat deal.

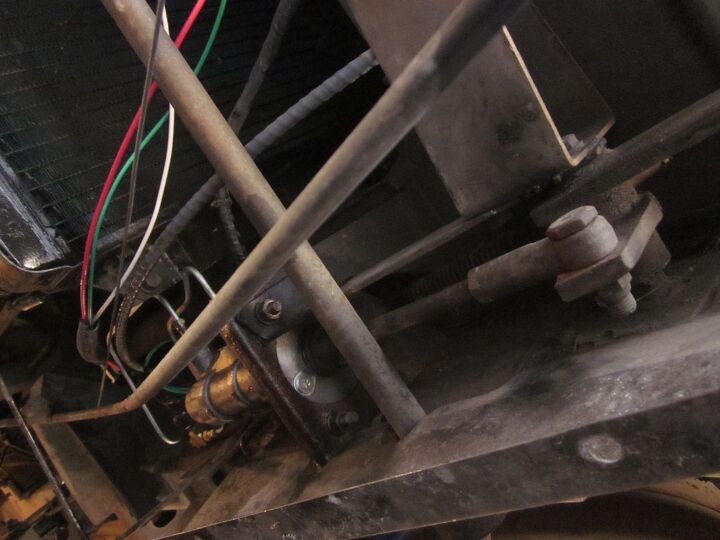

More sweat than we expected, because the A100’s forward-control setup necessitates a funky linkage-and-backward-mounted-master system. The master cylinder, which is actuated by a system of rods and pivots that appear to have been adapted from a piece of 1897 mining equipment, is located directly below the driver’s seat.

I’d assumed that Chrysler, once all their lobbyists had failed to fend off the dual-circuit brake demands of the US government— headed by arch-liberal integrationist Lyndon Johnson at the time, as if I needed to spell that out for you— would have found some cheap, bolt-in way of installing the slightly longer dual-circuit master cylinder, but it turned out that the ’66 master cylinder’s tack-welded-in-place splash shield didn’t have room for the ’67-and-up components.

So, the Sawzall had to be brought into play. This involved jarring loose 45 years of built-up crud, not to mention the opportunity to slice important stuff ranging from the wiring harness to the throttle cable.

Hacking this piece of sheet metal away means that some air destined for the radiator will slip past, so I might fabricate a replacement that fits the new master. I’ll see what happens when summer heat comes along; for now, the engine runs quite cool with this small opening next to the radiator.

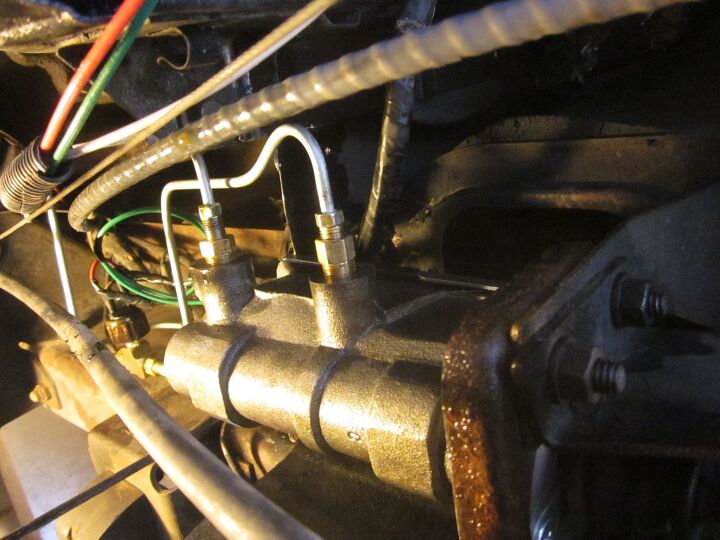

With the help of a $2.99 tube bender and some coat-hanger wire as a template, Rich starts work on the replacement brake lines.

I’ve never been able to do a double flare correctly, in spite of several very frustrating afternoons spent trying to do so in the past, so here’s the part I was especially glad to have Rich take on.

Modifying the plumbing was pretty straightforward; plug one port on the original four-way tee that once split the line from the master cylinder into one line to each front corner and one to the rears, using it for the front circuit only. Add another tee to send pressure to the rear brakes and signal pressure to the hydraulically-actuated brake light switch.

Bench-bleeding the new master cylinder.

To add fluid to the master cylinder in an A100, you must remove an access panel located on the floor just in front of the driver’s seat. Naturally, the access panel doesn’t quite fit the larger dual-circuit master cylinder, so a funnel must be used to get fluid to the rear reservoir. This process got brake fluid all over everything beneath, which made finding leaks a real challenge.

I didn’t trust the parked-for-12-years brake hoses, so I sprang for new ones all the way around.

After some bleeding, the new setup works fine. I’ll probably convert to front discs at some point, but for now I’m satisfied with drums that are less likely to fail. Anybody want to buy a genuine single-circuit A100 master cylinder?

Murilee Martin is the pen name of Phil Greden, a writer who has lived in Minnesota, California, Georgia and (now) Colorado. He has toiled at copywriting, technical writing, junkmail writing, fiction writing and now automotive writing. He has owned many terrible vehicles and some good ones. He spends a great deal of time in self-service junkyards. These days, he writes for publications including Autoweek, Autoblog, Hagerty, The Truth About Cars and Capital One.

More by Murilee Martin

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Orange260z I'm facing the "tire aging out" issue as well - the Conti ECS on my 911 have 2017 date codes but have lots (likely >70%) tread remaining. The tires have spent quite little time in the sun, as the car has become a garage queen and has likely had ~10K kms put on in the last 5 years. I did notice that they were getting harder last year, as the car pushes more in corners and the back end breaks loose under heavy acceleration. I'll have to do a careful inspection for cracks when I get the car out for the summer in the coming weeks.

- VoGhost Interesting comments. Back in reality, AV is already here, and the experience to date has been that AV is far safer than most drivers. But I guess your "news" didn't tell you that, for some reason.

- Doc423 Come try to take it, Pal. Environmental Whacko.

- 28-Cars-Later Mazda despite attractive styling has resale issues - 'Yota is always the answer.

- 28-Cars-Later Try again.

Comments

Join the conversation

On my 1981 Subaru GL, the Emergency Brake was actually connected to the front brakes. Sadly, if the brake pads decide to remove themselves from the front drivers side caliper (due to damage from a previous offroad excursion), not only will the regular brakes not work worth a damn, neither will the Emergency Brake. Needless to say this caused an airborn offroad excursion. Still drove the damn thing about a mile home with a nice trail of oil and antifreeze behind me.

I just saw this article 12 years after the fact when looking online to confirm that dual-circuit master cylinders were required starting in 1967. Please tell me that that first paragraph is a sick joke. These cars don't have "emergency" brakes. They have parking brakes, and if you've ever tried to stop by smashing the little pedal on the far left, you know that it does basically nothing. Yeah, if you're on an open road with several hundred feet of clear space ahead of you, you can stop safely, but if you're in traffic, you better jam into into first gear and pray.