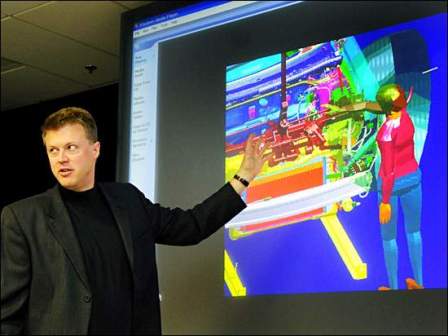

Ford Shows Off Virtual Production

Ford invited journalists over to check out its "virtual assembly" technology. (Our invitation was lost in cyber-space.) The Detroit Free Press came, saw and geeked out, leading off their breathless coverage with "If you want to know why Ford Motor Co.'s quality is improving so much…" But what exactly is this strange and mystical technology which makes otherwise credible journalists into so many ad copy writers? Combining motion-capture and computer modeling technologies, Ford "builds" model factories and inhabits them with avatar workers who virtually assemble vehicles. By analyzing how production operates virtually, Ford engineers can streamline and simplify the process. The result: better ergonomics and fewer injuries for production workers, improved production efficiency and quality improvements. AND the computer modeling allows Ford to develop production processes faster, so it can bring new products to market in less time. (Where? What?) Ford is so proud of their sim factory it boasts that productivity master Toyota is curious about the technology. Then again, ToMoCo knows that the map is not the territory.

More by Edward Niedermeyer

Comments

Join the conversation

The problem is that when the Detroit guys do take a 100,000 mile test car apart and lay the parts out, most of those parts are replacements of the originals. So, when the engineer looks at, say, an alternator and thinks it's in great shape after 100,000 miles, he's really looking at a third replacement alternator with 9,000 miles on it.

The problem from my point of view with the 100K mile test done under severe conditions is that it does not address things that happen with age. Plastics that get brittle, gskets that shrink or fail, etc. This does not necessarily address alot of scenarios that a car endures under normal use for a decade. An example the hot/cold cycling that the drivetrain does. Now, I'm an engineer and I have not worked as a durability test engineer so my opinion is worth only .005 cents more than any other guys. Anybody able to tells us the difference between the test procedures of an averager quality car like the Ford and that of a "star" preformer like the Accord? How would you explain a car that does okay and a car that really lasts and lasts. What is the difference in the way those cars are tested or designed?

I don't think a car get to 100K miles with replacement parts and nothing happens. It DOES in fact happens: the part that failed gets returned to the supplier or is analyzed, even if the test hasn't finished. Manufacturers also conduct durability tests on plastics, fabrics, etc... in labs under controlled conditions. As example, every metallic bolt in the car is tested inside a saline chamber for an amount of time at a given temperature to check if the covering resists corrosion... I agree with what was previously said here, it's like a 6 years old kid bragging about he can talk english. Ford, GM, Chrysler and Toyota and many others have been using these technologies for years... is not a big deal. If I am not wrong, Chrysler used it to set up the plant for the 1st Neon. And they have too, a mass production plant is very complex, standard operation time has to be reduced to a minimum and every bottleneck should be ruled out when the car enters production. And simulating the plant before entering production actually helps improve the assembly process, then assembly quality ;)