#AssemblyLine

Tesla's Feverish Production Drive Sometimes Means Partial Assembly at Stores: Report

Never has the air of breathless futurism surrounding Tesla taken such a hit. Following a revealing earning report and numerous reports of continuing production bottlenecks, this week wasn’t a good one for either Tesla shareholders or Model 3 reservation holders.

The electric automaker pushed back its 5,000-vehicle-per-week goal to the end of the first-quarter of 2018, rather than the end of this year. Its 10,000-vehicles-per-week goal remains a question mark. Tesla also announced a decrease in Model S and X production to bolster resources for Model 3 builds. In reporting a quarterly loss of $619 million, Tesla made it clear it’s burning through piles of cash in an attempt to smooth out production line hurdles.

Now, a new report sheds light on the frenetic activity occurring inside its Fremont, California factory. One of the claims certainly won’t soothe those worried about a long-standing Tesla concern: build quality.

General Motors Extends Summer Plant Shutdowns, Layoffs Likely to Follow

If your current employment involves building a sedan for a domestic automaker, there’s both good and bad news awaiting you. General Motors is extending summer breaks at certain assembly plants and there may be an opportunity for some workers to extend that time off indefinitely, resulting in the least welcome vacations imaginable.

Stagnating sales and a bloated inventory is forcing GM to lengthen its traditional two-week summer shutdown to as many as five weeks for two U.S. factories, according to union officials. The affected plants are Lordstown Assembly, located in Ohio, and Kansas City’s Fairfax Assembly. Lordstown assembles the Chevrolet Cruze while Fairfax is responsible for the midsize Malibu, which has had a horrendous 2017. The Malibu had plenty of company in the doldrums, too. Through May, U.S. car sales were down 11 percent while truck and SUV sales rose by nearly 5 percent, forcing automakers to play favorites.

Honda's Revolutionary Assembly Line Makeover Takes Workers on a Ride

Henry Ford’s way of building cars was so 20th Century, so Honda tried something new.

Workers at the automaker’s new Thailand plant now stay in motion all day, moving with the vehicle as it travels down the assembly line, Automotive News reports.

Robot Kills Man in Germany VW Plant

According to report from German-language HNA, a robot has killed a contractor in a Volkswagen plant in Germany, near Frankfurt.

The 22-year-old man, whose name has not released, was crushed against a metal plate by the machine. According to officials, operator error may have caused the man’s death.

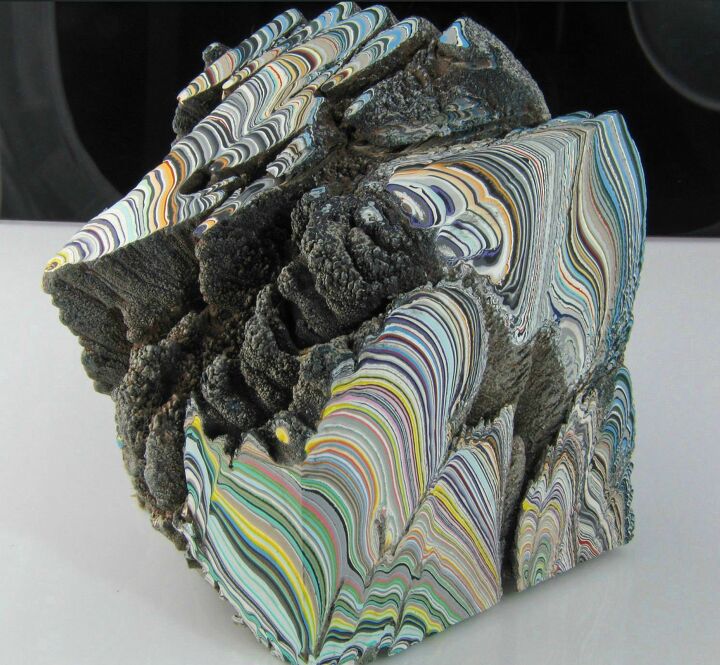

Beauty All Around Us: Artists Use Industrial Bi-Product To Make Jewelry

Imagine Detroit at its height, enormous factories and mile-long production lines running day and night, a roiling, churning symphony of man and machine where thousands of workers joined together parts, large and small, from a myriad of sources into single, working vehicle. Although I have toured modern factories in Japan, meticulously clean facilities where technicians in spotless coveralls only complete the tasks that robots cannot, I view the old factories, places like Rouge River that were built in in the first part of the last century, with a special sort of awe. The entirety of what went on there is, to me, unknowable and, like the great pyramids, all that is left of the human toil is the end product. That’s why, when some small piece of history, some bi-product of that mysterious past, catches my attention, I stop and look.

This Day In Automotive History: Model T Assembly Line Starts For First Time – October 7, 1913

Regardless of what you may read elsewhere today, October 7, 1913 was not when the first automotive assembly line was started up. Yes, 100 years ago today, after some experimentation at the Piquette Ave. factory, and then tested with magneto assembly, Henry Ford’s lieutenants at his Highland Park factory for the first time started up a moving conveyor line for the assembly of complete Model T automobiles. Ford Motor Company, though, was not the first automobile manufacturer to use an assembly line process.

Preservation Group Crowdsources Purchase of Ford's Highland Park Buildings, Reprises "Five Dollars a Day"

What remains of Ford Motor Company’s Highland Park plant, where the moving assembly line was developed and implemented.

Ford Motor Company’s Highland Park plant was the location of the first moving automotive assembly line a century ago this year. Henry Ford started to build the Highland Park complex in 1910, needing more capacity than he could produce in the Piquette Avenue plant. Getting away from Detroit taxes and more effectively being able to influence politics in the small municipal enclave within the Detroit city limits were also factors in Ford’s move. Much of the large complex, designed by famed architect Albert Kahn, has long since been demolished but a Detroit economic and community development group is trying to buy the plant’s office building, which still stands, and turn it into a center for information on automotive related attractions in the Detroit area.

Recent Comments