Nissan Charging Forward on Electric AWD, Solid-state Batteries

The Nissan Ariya Concept seen Wednesday at the Tokyo Motor Show will likely become a reality with little change in outward appearance, but you don’t need a sit-down with a group of Nissan engineers to figure that out. While the company admits an EV crossover is in the cards for the coming year (probably 2021 for the U.S.), the vehicle’s internals remain something of a mystery.

Shedding some light on the vehicle’s underbody bits, the Nissan engineers also opened up on a potentially revolutionary battery technology — as well as a detail that could help hesitant American drivers get behind the wheel of a (mostly) electric vehicle.

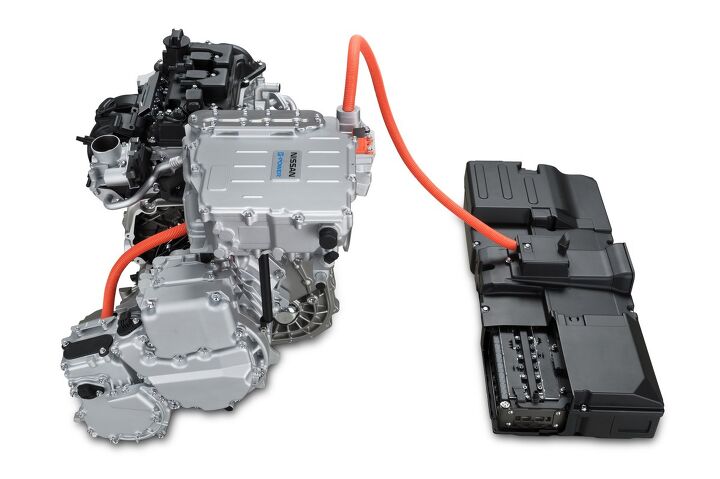

As reported by Automotive News, engineers speaking at Nissan’s tech center said the twin-motor AWD system found beneath the Ariya and a range of future products got its start beneath a Nissan Leaf test mule.

The prototype powertrain utilized twin 160-kilowatt motors front and aft, motivating each axle and drawing current from a 62 kWh battery pack sourced from the Leaf Plus. Models born from the joint Nissan-Renault dedicated architecture will use a different battery pack with different range and output, said lead system engineer Toshiyuki Nakajima.

In production vehicles, the system will meticulously tailor power delivery to the front and rear motors, with the brakes intervening to calm individual wheels in turns, he added. The project’s been underway for three years, with the home stretch apparently in sight.

Interestingly, Nakajima said the system can pair with something Americans might appreciate: Nissan’s e-Power system, which utilizes a continuously-running gasoline generator to provide current for the electric motors.

Already on sale in Japan, e-Power is expected to appear in Nissan and Infiniti vehicles in the near future. More efficient than having a gas engine power the drive wheels, e-Power is a novel take on the conventional hybrid. With this setup, torque-rich electric motors do all of the motivating, while nervous owners never have to worry about a battery pack running dry or finding a charging station. It’s like a range extender that never stops running. Another benefit is greatly reduced battery costs for that particular vehicle, and thus a lower sticker price.

The compatibility between the two-motor EV system and e-Power would allow Nissan to field BEV and gas-fired EV versions of models derived from the new platform.

As for batteries, Nissan has hopped on a bandwagon already populated by the likes of Toyota, among others. Hoping to increase energy density in EV battery packs while lowering overall costs, the engineers working on solid-state batteries also aim to reduce the size of today’s huge underfloor lithium-ion sleds. Don’t hold your breath, though.

As big as a breakthrough as solid-state batteries would be, it won’t be coming to a vehicle near you anytime soon. Even with the help of partners, Nissan doesn’t expect solid-state batteries in production vehicles until near the end of a 10-year window, according to Atsushi Teraji, the brand’s deputy general manager of powertrain and EV engineering.

[Images: Nissan]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Jeff I do think this is a good thing. Teaching salespeople how to interact with the customer and teaching them some of the features and technical stuff of the vehicles is important.

- MKizzy If Tesla stops maintaining and expanding the Superchargers at current levels, imagine the chaos as more EV owners with high expectations visit crowded and no longer reliable Superchargers.It feels like at this point, Musk is nearly bored enough with Tesla and EVs in general to literally take his ball and going home.

- Incog99 I bought a brand new 4 on the floor 240SX coupe in 1989 in pearl green. I drove it almost 200k miles, put in a killer sound system and never wish I sold it. I graduated to an Infiniti Q45 next and that tank was amazing.

- CanadaCraig As an aside... you are so incredibly vulnerable as you're sitting there WAITING for you EV to charge. It freaks me out.

- Wjtinfwb My local Ford dealer would be better served if the entire facility was AI. At least AI won't be openly hostile and confrontational to your basic requests when making or servicing you 50k plus investment and maybe would return a phone call or two.

Comments

Join the conversation

The "Solid State" batteries is what caught my attention. That would a giant leap forward. But, alas, a 10 year window? Much of technology tends to obsolete itself within 3-5 years! Just look how far we have come in cell-phone battery tech, or solid-state devices, or fuel-cell development, or ........

I'd much rather live in a world where the charging infrastructure is there to get rid of the ICE altogether, with its associated maintenance, complexity, and localized pollution, than where an ICE is needed as a crutch to make an EV workable. So I'm a lot more excited to hear about new charger installations and faster fast charging than gas generators. Always happy to hear about battery R&D, though. We still need to cut battery prices roughly in half before EVs will be cost-competitive on a lifecycle basis for non-fleet users.