Digging Deeper Into Volkswagen's MEB Platform Plans

Volkswagen walked journalists through its much-hyped electrification strategy at the 2019 Chicago Auto Show, giving the automotive media a preview of the automaker’s plans.

MEB, which is an acronym for the German Modularer Elektrobaukasten, is the platform underpinning the company’s push from internal-combustion engines to electrified vehicles. The company intends to roll out 50 battery-electric vehicles and 30 plug-in hybrids across Volkswagen Auto Group’s 12 global brands between this year and 2025 as part of a larger strategy to field 300 electrified vehicle models across the dozen brands by 2030.

That’s obviously an aggressive strategy — one requiring a closer look.

The usual caveat applies – VW was presenting to the media, so the company of course put its best face forward. That said, the automaker faced many good questions – and I am happy to pass good questions from the comments on to VW. If some of those queries stand out, and VW is willing to answer, maybe we’ll do a future post.

Until then, here’s a clearer look at what VW is trying to achieve.

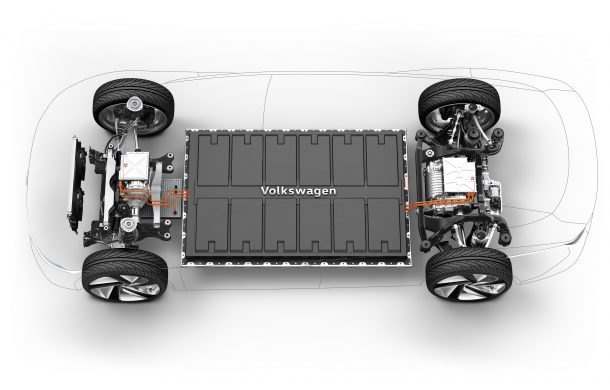

Starting with the basics, the MEB platform will be centered around the battery. Drivetrains will be all-wheel and rear-wheel drive, there will be a central computer system, and no center tunnel. VW estimates that trunk volume will be comparable to an internal-combustion engine vehicle.

That central computer will be able to provide over-the-air software updates, and there will be some level of autonomous driving capability. Customers will also have access to additional apps and services.

Range is always the key question when it comes to EVs, and Volkswagen estimates the MEB platform will provide at least 200 miles of range, with scalability up to 300 miles.

VW expects the MEB platform to have the flexibility needed to underpin vehicles of different heights, lengths, and widths. That’s due, in part, to the under-floorboard location of the battery. That battery location will also allow any MEB-based vehicle to feature a longer wheelbase and shorter overhangs than a comparable vehicle from the same class. VW says it will also offer more space in both the front and rear areas of the interior, as well as a higher seating position — again, when compared to vehicles in the same class, whichever class that may be. There’s also the option of outfitting a vehicle with larger wheels.

The choice of rear-drive or all-wheel drive is aimed at fulfilling VW’s desire for more responsive handling. Rear-drive vehicles will have a single electric motor mounted on the rear axle, while not surprisingly, the all-wheel drive models will have another electric motor mounted on the front axle.

Power specs are tentative, but we were told that the first rear-drive miles will have electric motors generating about 150 kilowatts of power. That’s a hair over 201 horsepower.

Chargers will be Level 3, which means an 80 percent “fill-up” will take under an hour. Still, VW expects most customers to charge overnight at home, using a lesser plug. The company also expects to have EV production online at its plant in Chattanooga, Tennessee by 2022.

As is usually the case when it comes to OEMs speaking on-record about future product, VW’s spokesman, Matthew Renna, vice president for e-mobility, North American region, was mum on much more than the basics. Exact vehicle types, names, and pricing are all under cover, although Renna made it clear that pricing will be aimed at mainstream buyers, and not just the well-heeled.

It’s an ambitious plan, to be sure. Not to mention a reaction to the diesel emissions scandal that is still rocking the company nearly four years after it began. Fifty new battery-electric vehicles in six years seems about as ambitious as me trying to complete stage one of American Ninja Warrior, although, to be fair, VW probably has better odds of success.

As Matt pointed out earlier this month, VW feels it has economies of scale on its side, and tightening emission regulations in Europe and China may push consumers towards EVs. Problem is, while VW would seem to have a leg up, most of its competitors are also preparing for any market shift.

The flexibility of the MEB platform is the key to potential success. That flexibility may keep costs low while also allowing VW to quickly add new models and variants to appeal to the broadest range of consumers possible.

Volkswagen is betting a lot of its future on MEB. Still, given the regulatory climate and the rapid advance of technology, it’s not necessarily a dangerous gamble.

At least Volkswagen hopes not.

[Image: Volkswagen]

Tim Healey grew up around the auto-parts business and has always had a love for cars — his parents joke his first word was “‘Vette”. Despite this, he wanted to pursue a career in sports writing but he ended up falling semi-accidentally into the automotive-journalism industry, first at Consumer Guide Automotive and later at Web2Carz.com. He also worked as an industry analyst at Mintel Group and freelanced for About.com, CarFax, Vehix.com, High Gear Media, Torque News, FutureCar.com, Cars.com, among others, and of course Vertical Scope sites such as AutoGuide.com, Off-Road.com, and HybridCars.com. He’s an urbanite and as such, doesn’t need a daily driver, but if he had one, it would be compact, sporty, and have a manual transmission.

More by Tim Healey

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- 3SpeedAutomatic Elon took his eye off the ball while pre-occupied with "X" (formerly Twitter). Now, Tesla is coming around and biting him on the arse!!In the car business, you need to keep you finger on the pulse. Momentum will only carry you so far. If in doubt, think Lordstown and Fisker. He thinks technology will solve his problems. However, Telsa has moved from premier product to commodity with other manufacturers entering his exclusive domain. Time for Elon to fly back to Tesla HQ and come up with a long term plan. 🚗🚗🚗

- Irvingklaws Anymore seems I want a color that is not black, white, red, or some shade of silver/gray. Though I coveted them when I was younger, I also seem to have developed an aversion to all-black interiors. I have a deep negative reaction to any vehicle identifying as "triple black". Don't even get me started on black wheels...I'm not the only one. We're looking to replace my wife's silver CX-5 and one of her few non-negotiable prerequisites is that it be "a color" not in the aforementioned list. It's looking like a Cascade Green Forester with a light gray interior is in her future.

- Bd2 I dig it, Pure Pazaak!

- 3-On-The-Tree My C6 is all blacked out, the rims are matte black and interior all black with no contrast. I was never a fan of chrome rims and lots shiny chrome/silver trim etc.

- JMII Here are all the colors I've owned in order: tan, red, black, red, yellow, green, green, black, blue, silver, white, orange, red, blue and blue.So yeah I love colors...

Comments

Join the conversation

This MEB platform is dead on arrival. Why? Because charging will take about an hour and only charge 80 % of the battery! Those specifications are simply unacceptable for a vehicle of any propulsion type in 2019. Charging the battery to 100 % shouldn't take more than five minutes. VW better go back to the drawing board, or this MEB will be a fiasco of such proportions that Dieselgate will pale in comparison.

Aufbocken, aufbocken, aufbocken und es wird sich gut verkaufen!