Dodge Centennial: How To Build A Car And A Car Company, In Three Notebooks

The Dodge brand’s centennial celebration began this week with the announcement of special 100th Anniversary Editions of the Dodge Challenger and Charger. After more than a year of preparation, John and Horace Dodge went for a ride in public in a car with their own brand for the first time on November 14, 1914. That was after eleven years of supplying Henry Ford and his car company with every major component of Ford cars except for bodies, wheels and tires. The critical role that the Dodge brothers had in the success of Henry Ford and the Ford Motor Company is not widely known outside of serious Dodge and early Ford enthusiasts. It has been reliably estimated that from the founding of the Ford Motor Company in 1903 until 1914. when the Dodges ended their contracts with Ford, they supplied about 60% of the total value of the cars that Ford “built”. Without the Dodge brothers, Ford Motor Company would never have gotten off the ground.

Horace and John Dodge in the first Dodge automobile, Nov. 14, 1014. Photo taken in front of John Dodge’s Boston Blvd. mansion in Detroit’s prestigious Boston-Edison district.

It wasn’t a very smooth relationship. Henry Ford changed the world but in many ways he was a megalomaniacal and manipulative crackpot. Having lost the Henry Ford Company to backers who turned it into Cadillac, Henry didn’t want to be beholden to financiers and stockholders, but the realities of business meant that he did have a small number of investors in Ford Motor Co, including his business manager James Couzens, his lawyer Horace Rackham, and the Dodges, who were paid in stock when Ford was short of cash.

So while supplying Henry had its headaches, it also made Horace and John Dodge very wealthy men, doubly wealthy in fact. They made about $2 million supplying Ford and they made even more money, $5.4 million, from dividends on their Ford stock. Unfortunately, Henry ran the company as though he had no stockholders, sometimes hoarding company cash for his own plans rather than paying out customary dividends. Eventually there were lawsuits, threats by Henry Ford to start an entirely new car company to compete with FoMoCo, and low ball offers before he paid the Dodges $25 million in 1919 dollars (for their original 1903 investment of $10,000) but in 1913, that was well into the future.

While they already made two fortunes from their relationship with Ford, by 1913 they were not thrilled about continuing to make parts for the Model T. If you think automotive technology changes rapidly today, imagine how quickly things advanced a century ago. In five years the Model T went from state of the art to technologically lagging its competitors but Henry thought it was the perfect car. Ironically, by the time the T started selling in really huge numbers in the nineteen teens it was obsolete and being technologically surpassed by by more modern cars. The Dodges were good engineers, probably the best machinists in Detroit next to Henry Leland. The term “mechanical genius” could have been coined for Horace Dodge and his brother John was almost as adept with his own management skills. By 1914 the Dodge brothers, who already owned and operated what was probably most advanced automotive plant in the world in the Detroit enclave of Hamtramck, wanted to build modern machines.

If you look at the historical record, Henry Ford eventually had fallings out with many of his close associates, including his business manager, James Couzens, and his pastor, Samuel Marquis, so the Dodges’ disaffection from Henry Ford was not that unusual. Not only were they tired of dealing with Henry’s eccentricities, and tired of building an old fashioned car, they knew that they were increasingly vulnerable having such a big customer, a customer that had already started making many components himself, on his path to making FoMoCo perhaps the most vertically integrated manufacturing company ever. One reason why people don’t know about the Dodges’ role in Ford history is because Ford was later famous for making every part of their cars, including the raw steel and glass. In the early days, though, Ford, like most automakers then, was an assembler, buying components and subassemblies. The Dodges supplied other automakers like Cadillac and Oldsmobile, but Ford represented the lion’s share of their business. So the Dodges had plenty of reasons in 1913 to jump before they were pushed and in July of that year they gave Henry Ford a year’s notice that they’d no longer be supplying him. Soon, the automotive world was abuzz with the news that Dodge Brothers would be making a Dodge car.

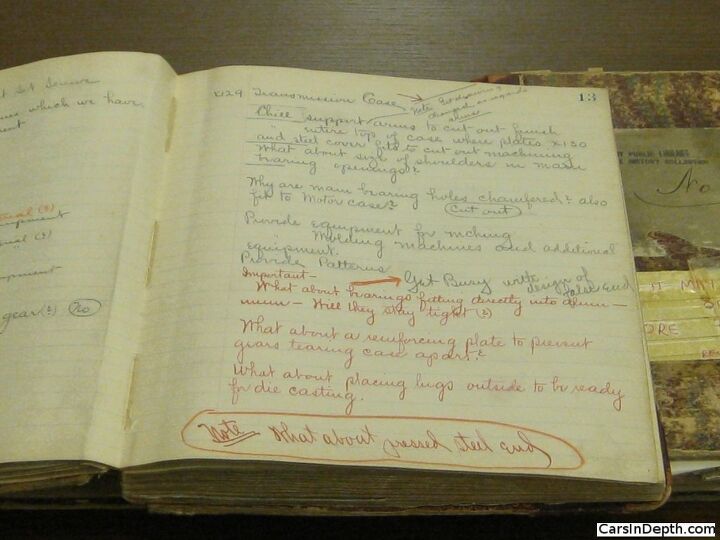

The thing is, though, you can’t just start a car company, even if you’re one of the largest automotive suppliers in the world, then or now. By 1912, the Dodges had already hired Frederick Haynes, an experienced “motor man” to both run their production facilities and start planning for the production of a Dodge automobile. Haynes and the Dodges planned the new car and the factories to build it in meticulous fashion, literally down to the bolts and nuts. We know just how meticulously they did all that planning because we have a mostly handwritten account of everything they did as they prepared to start building their own car and then put it into production.

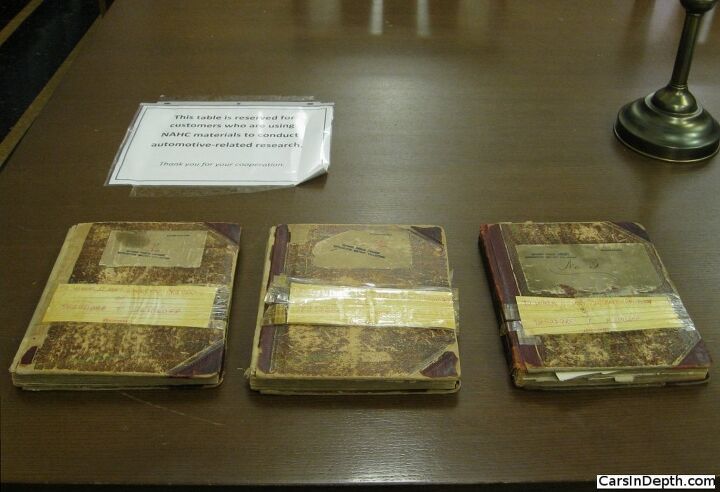

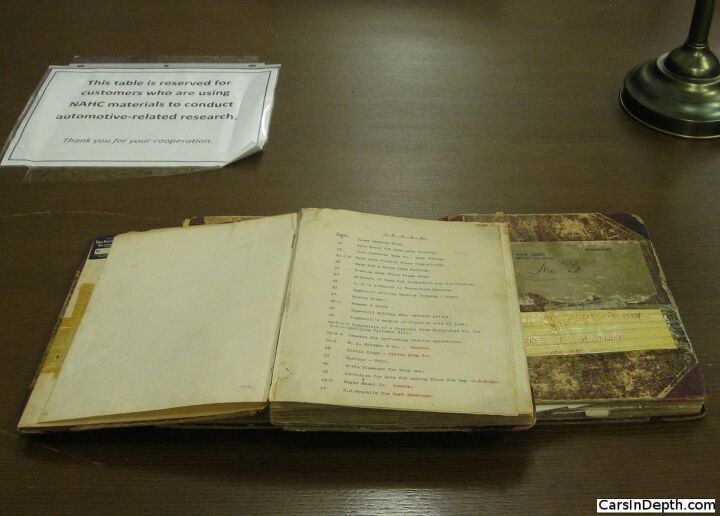

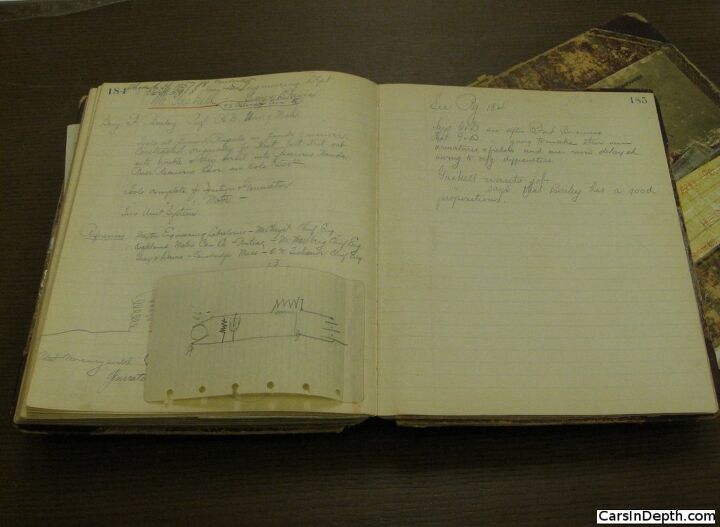

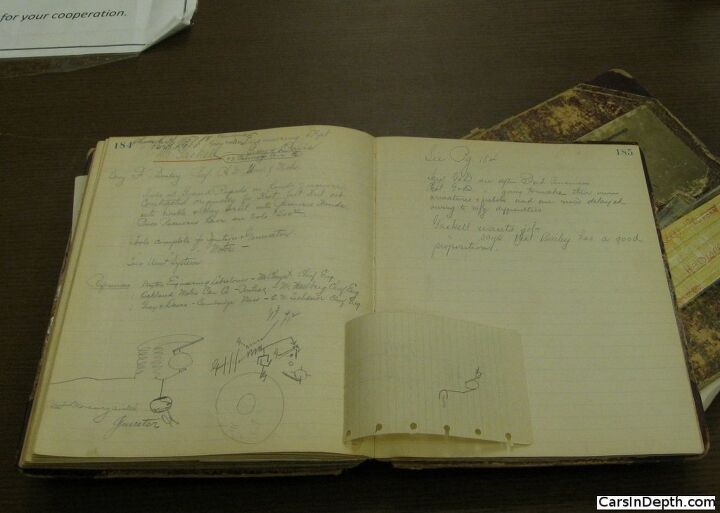

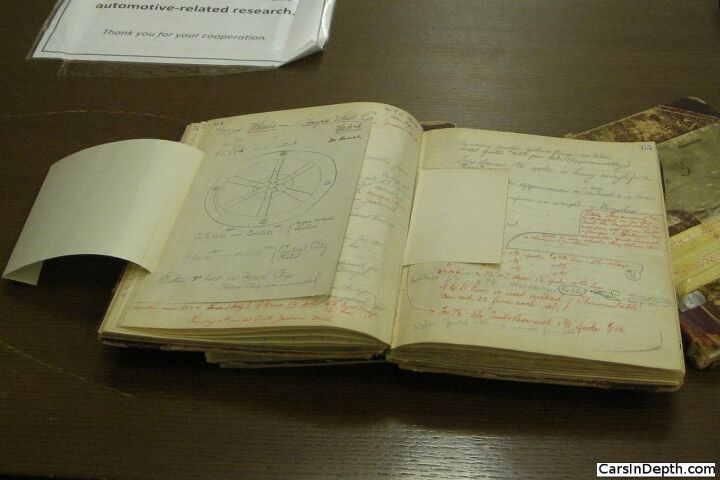

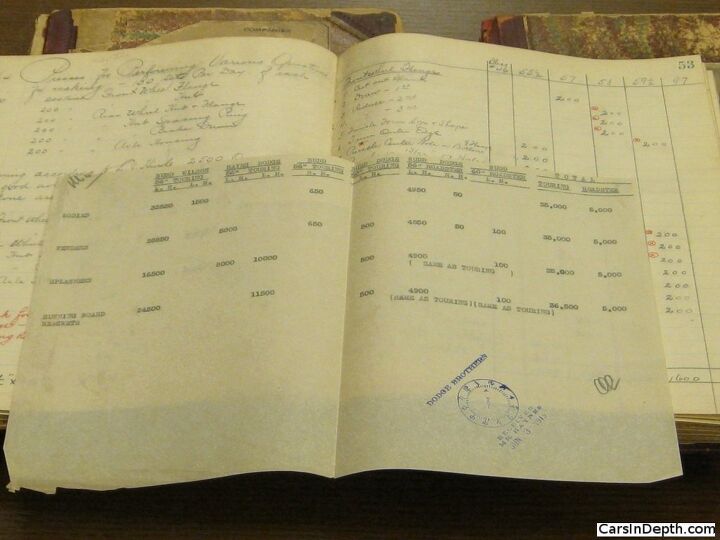

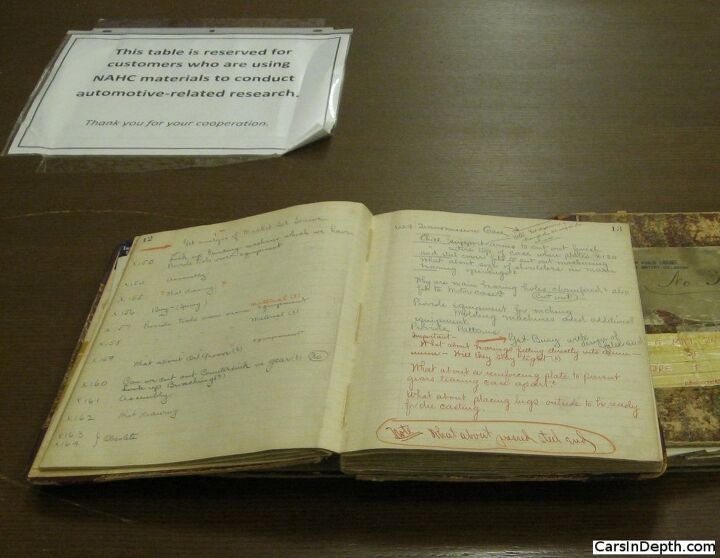

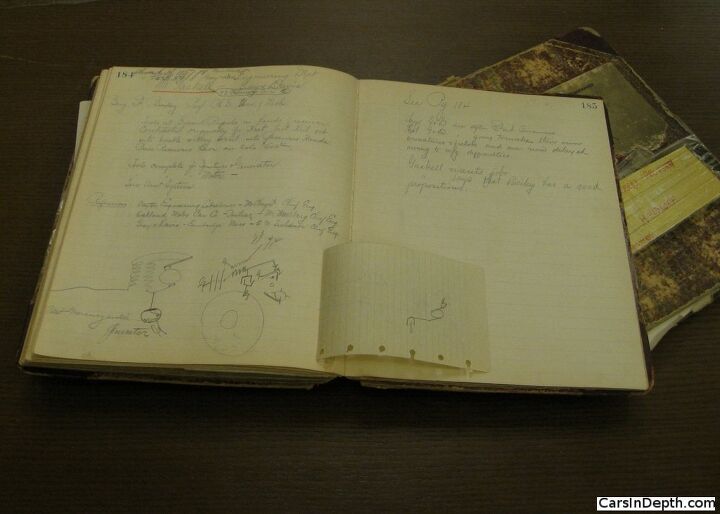

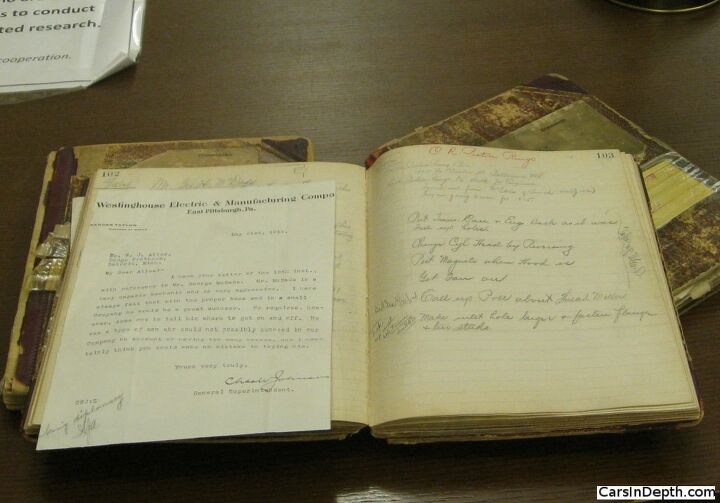

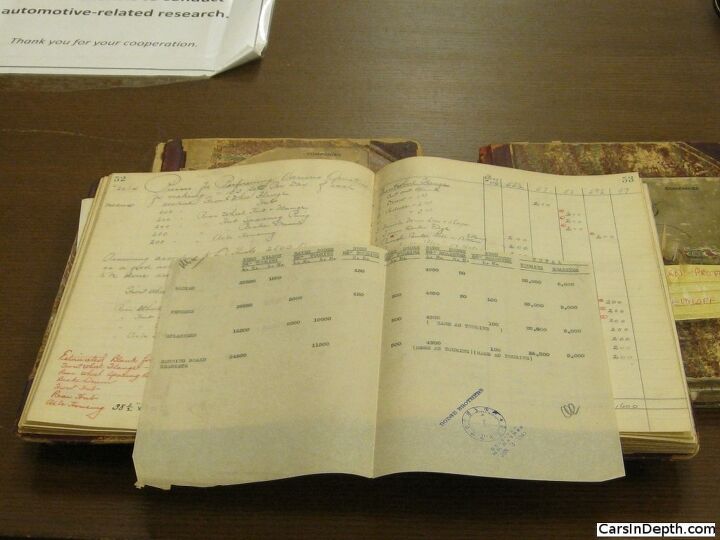

The account is in the form of three hardbound notebooks that are now in the National Automotive History Collection of the Detroit Public Library. Each has a label taped to the cover saying that it’s the property of one Theodore T. Heidloff but there’s little doubt that Haynes wrote and compiled it.

The first volume, which covers the period from March 1913 to July 1914, contains cost, specifications and quality information for components like frames, wheels, tires, bearings, pistons and piston rings, as well as batteries and ignition systems from more than a hundred potential suppliers. Also included are proposals from machinery suppliers and Dodge Brothers’ evaluation of the proposals and the machinery.

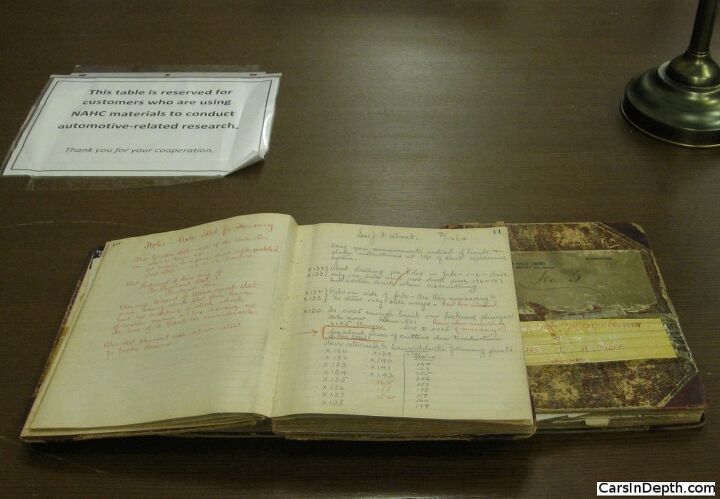

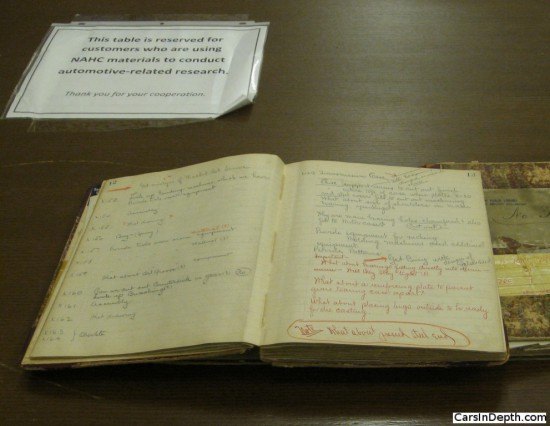

The notebooks show just how collaborative the process working with vendors was. One section of the first notebook has John Dodge’s detailed suggestions and drawings for improving and speeding up the process of drilling cylinders in engine blocks.

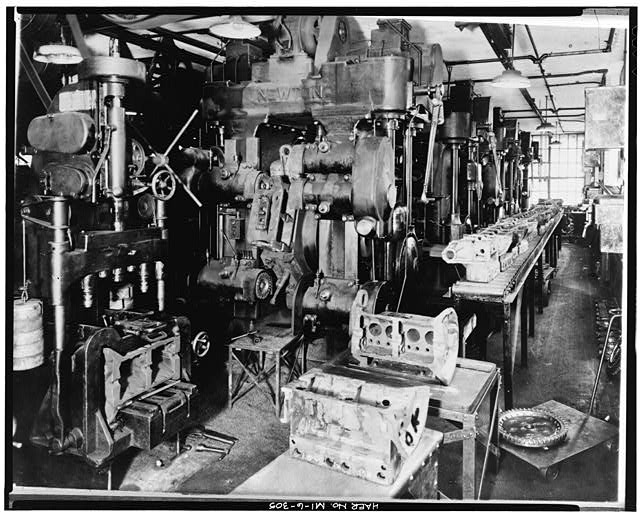

Dodge engine blocks being machined in 1915. If you searched, you’d find reference to all of those machines in the notebooks.

Once a vendor was chosen, blueprints had to be drawn and the notebook lists hundreds that the compiler had checked and approved.

Processes are suggested and then revised or alternatives questioned, usually in red pen. The evaluations of the suppliers are frank. In one case regarding a stamped part, a supplier said that it could be made with a single stroke, but just in case, they’d be building up the dies to withstand a second strike. The compiler notes that he doesn’t believe they’d be able to make the part with a single stamping operation.

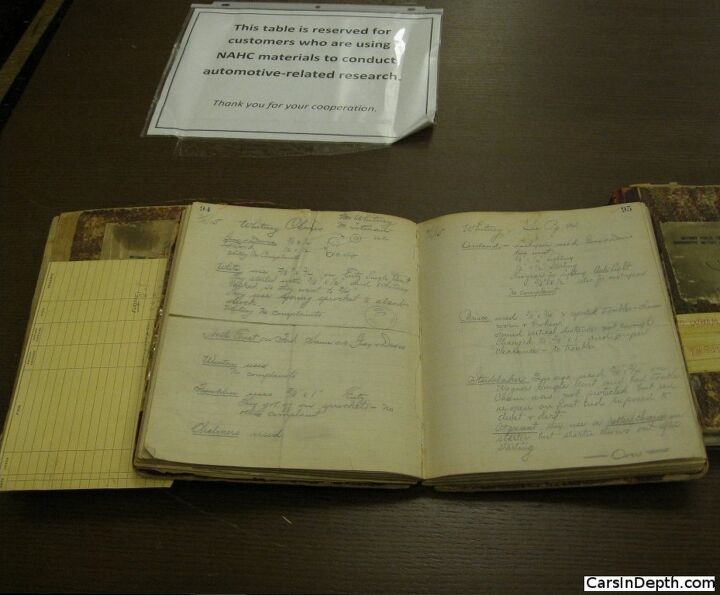

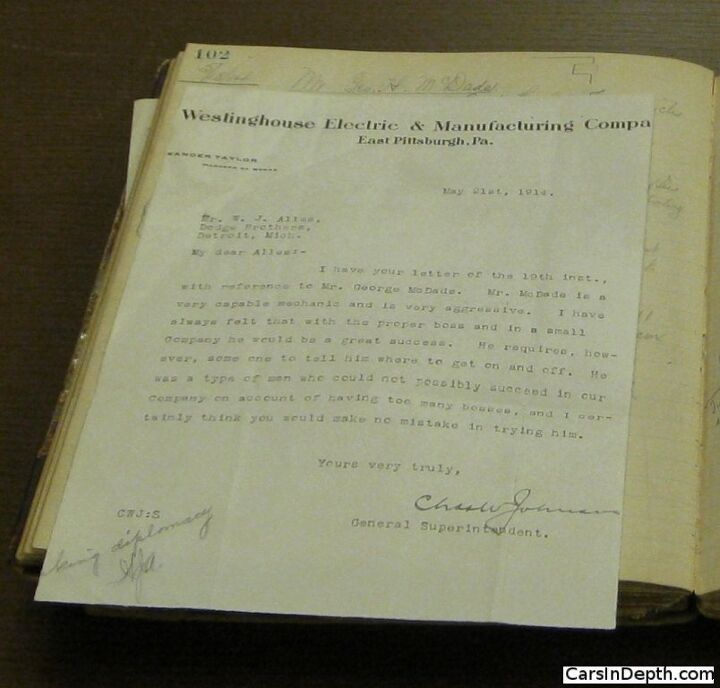

The second notebook covers the period, July 1914 to July 1915, when the Dodge Brothers automobile actually went into production. As a result, in addition to materials like in the first volume, the second notebook also contains detailed personnel information. When the Dodges started promoting their new company, even before the car was designed, they were flooded with applications from mechanics, engineers and managers looking for work. Included in some cases were letters of recommendation from previous employers.

While going through the notebooks, when I showed the NAHC librarian a recommendation letter for one Mr. George McDade, she laughed out loud and said that a former employer today would never send out such an honest letter:

Westinghouse Electric & Manufacturing Company

May 21st, 1914.

Mr. W. J. Alles,

My dear Alles:-

I have your letter of the 19th inst.. with reference to Mr. George McDade. Mr. McDade is a very capable mechanic and is very aggressive. I have always felt that with the proper boss and in a small Company he would be a great success. He requires, however, some one to tell him where to get on and off. He was a type of man who could not possibly succeed in our Company on account have having too many bosses, and I certainly think you would make no mistake in trying him.

Yours very truly,

Charles Johnson

General Superintendent

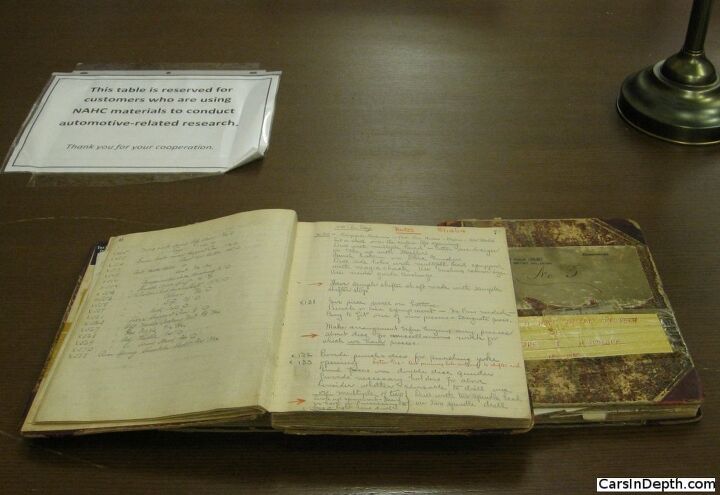

The second notebook also contains information on how the new factories were outfitted. There are pages of diagrams on the layout of the main plant including materials handling systems, machinery placements and die management. In addition to the manufacturing side of things, the notebook also covered administrative tasks under the heading “Our Office – Things to Do” followed by “How to Do Them” with a list of men appropriate for the tasks.

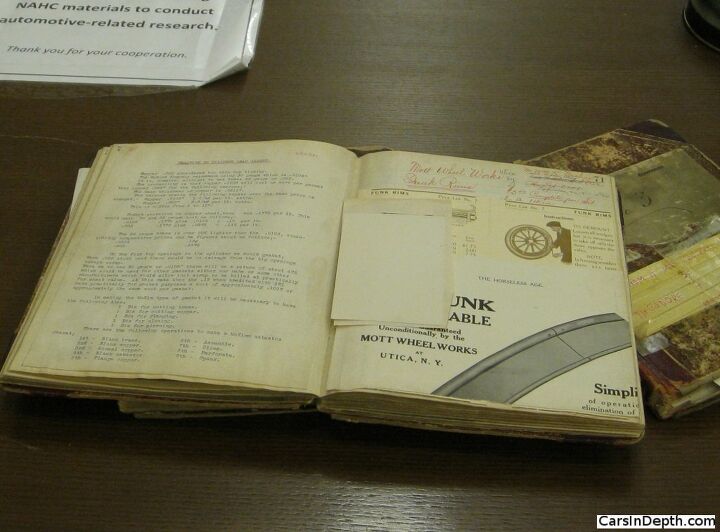

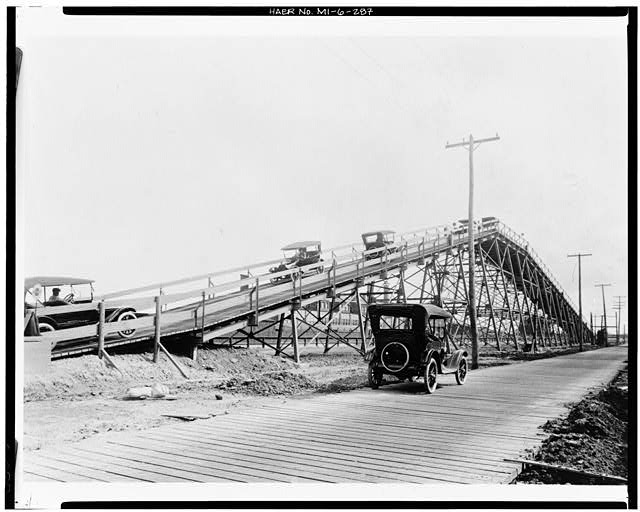

The third notebook, from April 1915 to June 1916, shows how conscientious the firm was about continuous improvements. It was in 1915 that Dodge built the first automotive test track in the Detroit area, adjacent to their Hamtramck factory, to test cars after production.

Dodge test track, Hamtramck, Michigan, 1915

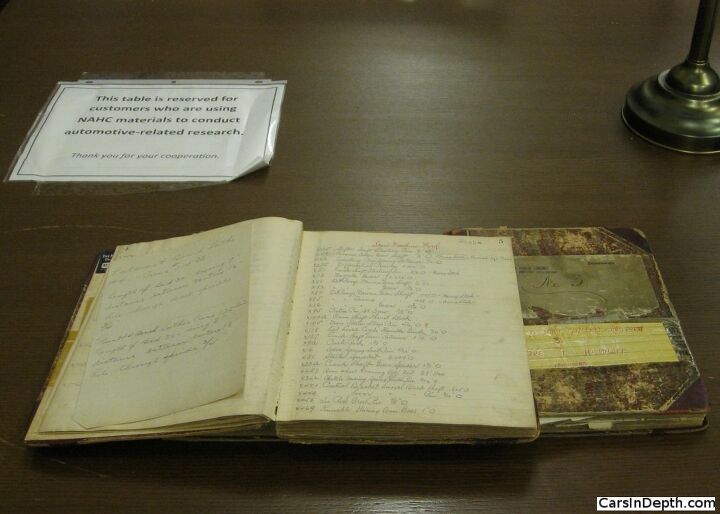

Volume #3 has more information on suppliers and alternatives. For example, there are ten pages of detailed comparisons between Exide and Willard batteries. The Exide was available worldwide, had a better reputation and it weighed significantly less, but it was also 30 cents per car more expensive.

The third volume also includes notes on visits made to seven different rolling mills, comparing plants, equipment and processes before deciding on a sheet steel vendor. Likewise they evaluated body suppliers before settling on the Edward G. Budd Mfg. Co. as a principal vendor. The notebook clearly indicates that the relationship was rocky. Numerous entries talk of “settlements” and “repair” work that needed to be done.

Besides being an irreplaceable historic artifact, the content in the Dodge Brothers notebooks at the NAHC gives us an incredibly unique and altogether fascinating look at the early days of automotive manufacturing and into the personalities involved as well, like Haynes, Budd and the Dodges. You get an idea of just how monumental a task it was to start a car company 100 years ago and though people use computers these days instead of paper ledgers, it probably wouldn’t be a bad idea for today’s automotive entrepreneurs to take a look at the Dodge Brothers notebooks. Small wonder that historian Charles Hyde (whose book on the Dodges provided much of the information in this post) describes them as “a primer on launching a new automobile”.

Ronnie Schreiber edits Cars In Depth, a realistic perspective on cars & car culture and the original 3D car site. If you found this post worthwhile, you can get a parallax view at Cars In Depth. If the 3D thing freaks you out, don’t worry, all the photo and video players in use at the site have mono options. Thanks for reading – RJS

Ronnie Schreiber edits Cars In Depth, the original 3D car site.

More by Ronnie Schreiber

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Tassos Tim is not that good with colors.The bright "pink" is not pink, but FUCHSIA. Both colors may look good on a woman's sweater, but not on steel panels.

- Tassos While I was a very satisfied owner of a much earlier Accord COupe 5 speed (a 1990 I owned from 1994 to 2016), I don't like the exterior styling of this one so much, in fact the 2017 sedan looks better. Or maybe it sucks in white. The interior of my 1990 was very high quality, this one looks so-so. The 157 k miles were probably easy highway miles. Still, Hondas are not Toyotas, and I remember the same service (like timing belt replacement) back then cost TWICE for an Accord than for a Camry. Add to this that it has the accursed CVT, and it's a no. Not that I am in the market for a cheap econobox anyway.

- 3-On-The-Tree My 2009 C6 corvette in black looks great when it’s all washed and waxed but after driving down my 1.3 mile long dirt road it’s a dust magnet. I like white because dust doesn’t how up easily. Both my current 2021 Tundra and previous 2014 Ford F-150 3.5L Ecobomb are white

- Bd2 Would be sweet on a Telluride.

- Luke42 When will they release a Gladiator 4xe?I don’t care what color it is, but I do care about being able to plug it in.

Comments

Join the conversation

Mr. Schreiber, thanks emensly for your article. The early 1900's are one of my favorite times in history. And the automobile industry and things pertaining to Henry Ford is one of my favorite subjects. As one who has studied and been in manufacturing for much of my life, such artifacts as this book are exciting for one like myself to discover and explore. Thanks for your interest in the material, bredth of coverage and overall contribution to this site.

Thanks Ronnie for the article and thanks to all those who have commented, I always find your articles and other TTAC articles informative and I always learn something that I didn't know before. The book about Steve Jobs and Microsoft is very much like this article. The stories of founders of Sony and Honda are similar to this as well even though they are from a different part of the World (Japan). I remember when one of the Dodge widows died in the early 70s and all the Dodge cars that were in her possession were sold off (many had been stripped of their parts). Thanks again for the great article and the great discussion.