Sayonara, Toyota Quality

Parts suppliers in Japan had near death experiences when they opened their Nikkei [sub] this morning. Parts suppliers in China and the rest of the world suffered heart and respiratory problems when the news of Toyota’s latest plan hit the news-wires.

In search of money to save, Toyota plans to slash its parts procurement expenses by 30 percent over the next three years.

Toyota told parts manufacturers to cut prices for auto parts to be used in cars that will be released in and after 2013. The cuts affect more than 200 power train, body and chassis components.

This is easier said than done. Parts sold to OEMs are typically made at razor-thin margins. There is only one way to come close to the cost reductions planned: Make the parts from less expensive materials, and dispense with the really expensive parts,

In that vein, Toyota spokesman Takanori Yokoi said the automaker had made “various suggestions including cost reductions” to suppliers, says Reuters. Toyota plans to overhaul its car designs to help cut costs.

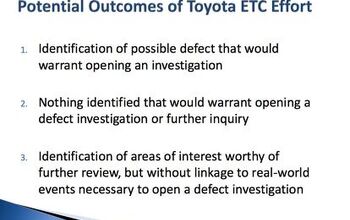

This can only mean one thing: The previously vaunted Toyota reliability, which already started to suffer a while ago, will go further down the drain. The reliability problems were one of the results of a cost-cutting campaign by Toyota that started in 2006.

The news was received with “Hurrah!” on the top floor of the Volkswagen-Hochhaus in Wolfsburg. VW wants to dethrone Toyota by 2018. The cuts in quality will play right into the hands of Volkswagen. They had to contend with their own quality problems ,and had stomach convulsions whenever a German J.D. Power study came out with Toyota on top, and VW down below mediocre.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Comments

Join the conversation

Why build a vehicle that someone will buy and keep 10+ years when you can build a POS that people will lease every 2 years?

The solution is obvious for "cutting the part count in engines by 20%." Air-cooled two-cycle motors like Lawn Boy mowers used to have! They'll have to bring 'em in while the EPA is on coffee break, of course. Menno, nice to hear from you again. Hope the Subaru serves you well in this new era of DIY highway maintenance.

Jeez... Reduction in cost.. Whatever happened to working the pricing out in the standard build / design procedure of the average vehicle? Are they taking notes from GM? I feel like they / we are on the top of a roller coaster.. looking up.. and slowly click click click click clicking the way over the top.. before the loong ride down.